|

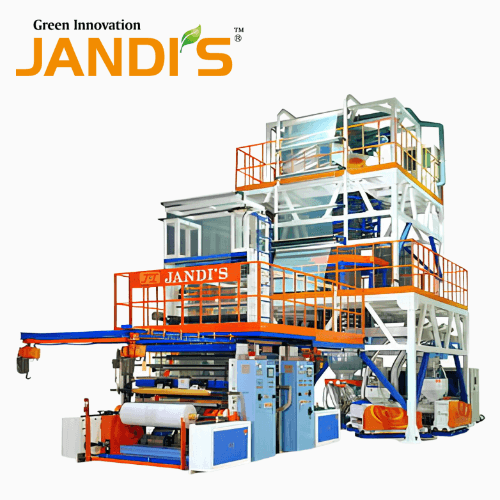

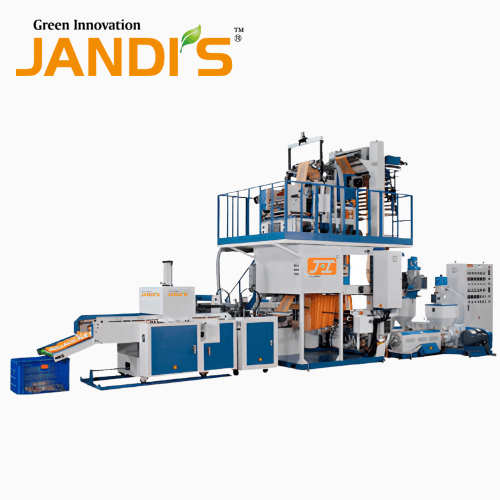

A-B-C 3 LAYER CO-EXTRUSION FILM INFLATION MACHINE |

||

|

|

MODEL |

GF-L3C-MT-1800 |

|

FEATURE |

MATERIAL TO BE USED |

LDPE / LLDPE / mLLDPE / HDPE / EVA / PP |

|

MAX. FILM WIDTH |

FLAT FILM 1800mm ; WITH GUSSET 2500mm (5000mm OPEN WIDTH) |

|

|

FILM THICKNESS |

0.020 ~ 0.20mm (THINNER or THICKER GAUGE REQUIRED, TO BE SPECIFIED BY BUYER) |

|

|

LAYER RATIO |

1:1:1 TO 1:3:1 |

|

|

EXTRUSION OUTPUT |

Max. 650kg/hr |

|

|

MAX. PRODUCTION CAPACITY |

550kg/hr for

1:1:1 |

|

|

REAL PRODUCTION OUTPUT |

REAL PRODUCTION OUTPUT DEPENDS ON THE MATERIAL, FILM SIZE, OPERATION CONDITIONS, SKILL & EXPERIENCE |

|

|

THICKNESS TOLERANCE |

+/- 3 to +/-

10% |

|

|

EXTRUDER

(THREE SETS)

|

SCREW DIAMETER

|

75mm x 2 |

|

SCREW L/D RATIO |

30:1 |

|

|

DRIVING MOTOR |

100HP X 2,

INVERTER CONTROL |

|

|

EXTRUSION CAPACITY |

75mm : Max.

200kg/hr |

|

|

CO-EXTRUSION DIES |

ψ400mm (or to

be specified by buyer), EUROPEAN DESIGN |

|

|

CONTROL PANEL

|

TYPE |

INDEPENDENT TYPE SWITCH BOARD (BOX), CE STANDARD |

|

TEMP. CONTROL |

PID

TEMPERATURE CONTROLLERS, COLD-START PROTECTION |

|

|

COOLING UNIT |

EXTERNAL COOLING |

FULL-AUTOMATIC

THICKNESS CONTROL, EUROPEAN DESIGNED FLYER AIR RING |

|

INTERNAL COOLING |

EUROPEAN DESIN

IBC DISKS |

|

|

AIR BLOWER |

20HP, INVERTER CONTROL |

|

|

TAKE-UP UNIT |

FIXED TOWER, HEIGHT |

12.5 M |

|

OSCILLATING HAUL-OFF |

HORIZONTAL

TYPE, SITTING ON SLEWING RING BEARING, |

|

|

TAKE UP ROLLER |

1900mm |

|

|

TAKE UP MOTOR |

3HP, INVERTER CONTROL |

|

|

TAKE-UP SPEED |

MAX. 60M/min or TO BE SPECIFIED BY BUYER |

|

|

BUBBLE GUIDE |

CAGE TYPE,

UP/DOWN BY MOTOR DRIVEN |

|

|

STEADY PLATE |

MOTOR DRIVEN TYPE , MADE OF ALUMINUM ROLLERS |

|

|

GUSSET BOARD |

450mm DEPTH, MOTOR DRIVEN |

|

|

GUIDE UNIT |

TWO SETS A.C. MOTOR + INVERTER |

|

|

WINDING UNIT |

SCGC TYPE |

SURFACE / CONTACT / GAP / CENTER, 4-IN-1, FULL-AUTOMATIC, HMI CONTROL, TWO STATION WINDER |

|

BOBBIN CHANGE |

PNEUMATIC SYSTEM |

|

|

FILM CUTTING |

PNEUMATIC SYSTEM |

|

|

EFFECTIVE WIDTH |

1800mm |

|

|

WOUND-UP DIAMETER |

Max. 800mm |

|

|

SURFACE WINDING |

2HP, INVERTER CONTROL |

|

|

CONTACT/GAP/CENTER WINDING |

3HP, INVERTER CONTROL, SERVO MOTOR FOR POSITIONING |

|

|

AIR SHAFTS |

3” x 3 PCES ON

EACH WINDING STATION, TOTAL 6 PCES ; |

|

|

SIDE-OPENING |

TWO SETS, AIR BLOWING TYPE |

|

|

SLITTING DEVICE |

SINGLE-BLADE UNIT X 2 SETS, DOUBLE-BLADE UNIT x 2 SETS |

|

|

TENSION CONTROL |

AUTOMATIC TYPE, WITH LOADCELLS |

|

|

UNLOADING UNIT |

HYDRAULIC SYSTEM, ONE ON EACH SIDE |

|

|

OTHERS TO BE INCLUDED |

- 4-COMPONENTS GRAVIMETRIC DOSING UNIT

x 3 SETS

- EXTRUSION CONTROL (YILED & GRAM PER METER CONTROL)

- 4-IN-1 MATERIAL AUTO LOADING SYSTEM* 3 SETS

- PRESSURE & MELTING TEMP. GAUGE x 3 SETS

- AUTO FILM GAUGING SYSTEM WITH OSCILATING RING TO WORK WITH AUTO AIR RING

- AUTOMATIC WIDTH CONTROL

- MONITORING & SUPERVISING SYSTEM, WITH 15” HMI SCREEN, TO CONTROL

MATERIAL RECIPES / PRODUCTION OUTPUT / FILM WIDTH / FILM THICKNESS / IBC.

- EDGE POSITION CONTROL (EPC)

- AIR CHILLING SYSTEM, WATER COOLING TYPE (WITH COOLING TOWER & WATER

PUMP)

- EDGE-TRIM WINDER, 2-SPINDLE TYPE

|

|

|

OPTIONS |

5.0 KW CORONA TREATER, HEAT-SLITTING UNIT, 6” AIR SHAFTS or 6” AIR CHUCKS, CENTER POSITION CONTROL(CPC), AIR COOLING TYPE AIR CHILLER ….etc. |

|

|

REMARKS |

* Final specifications of the co-extrusion machine depend on the film application, material to be used, accepted thickness tolerance, and your special requirements. |

|

-

Équipement Auxiliaire & Automatisation Intégrée

Compresseurs d Systèmes d'assemblage Machine de Soudage Automatique Presse à balles Équipement de contrôle Équipement de refroidissement / refroidisseurs industriels Machines de découpe Équipement de dosage et de mesure Séchoirs et déshumidificateurs pour matières plastiques Mangeoires Machines à poinçonner hydrauliques Équipement de pulvérisation Indicateurs et capteurs Robots industriels Logiciel industriel Équipement d'inspection et d'essai Machines de Chargement et de Transport Stockage de matériel Systèmes de changement de moule Machine de meulage en plastique Auxiliaires de machine d'impression Changeurs de Filtres / Filtres Séparateurs Équipement de traitement de surface

-

Machines de Moulage par Soufflage

Machines de moulage par soufflage automatiques Machines de soufflage multicouches Machines de moulage par soufflage par stations Machines de cristallisation Machines de moulage par soufflage électriques Machines de soufflage par extrusion Machines de soufflage horizontales Machines de soufflage hydrauliques Machines de soufflage par injection

-

Extrudeuses et Lignes d'Extrusion

Extrudeuses de film / feuille à bulles d'air Extrudeuses de film soufflé Machines de soufflage par coextrusion Machines de revêtement par extrusion Machines de plastification par extrusion (type enduction à chaud) Lignes d’extrusion pour filaments et fils Lignes d’extrusion pour tuyaux et profils Lignes d'extrusion de films et de feuilles Extrudeuses de Mousse Machines de Plastification Industrielle Medical Tubing Equipment Machines de fabrication de tubes en plastique Machines de revêtement par héliogravure Extrudeuses Monovis Machines d’Extrusion de Rubans Extrudeuses Bi-vis

- Produits Finis / Semi-finis / OEM / ODM

-

Machines de Moulage par Injection

Machine de Moulage par Injection Automatique Machines de Moulage par Injection Électriques Machines de moulage par injection à haute pression Machines de Moulage par Injection Horizontales Machines de Moulage à Fermeture Hydraulique Dans les machines de moulage par injection d Machines de Moulage par Injection selon la Couleur Machines de moulage par injection par boucle Machines de Moulage par Injection par Type de Plaque Machines de moulage par injection de moulage par insertion Machines de moulage par injection basse pression Machines de moulage par micro-injection Machines de moulage par injection de préformes Machines de moulage par injection à verrouillage à genouillère Machines de Moulage par Injection Verticales

- Moules et Filières

-

Machines d’Emballage

Machines de capsulage Machines d’emballage de capsules / comprimés Machines à cartonner Machines d'emballage à sec Machines à étiqueter Machines de Conditionnement de Liquides Machines de Soudure Machines d’Étiquetage Thermorétractable Dispositifs d Machines de cerclage Machines d'emballage de paille Machines d Équipements d’Emballage

- Pièces et Composants

-

Machines de Conversion du Plastique

Machines de fabrication de sacs par application Machines à gaufrer Machines à tricoter industrielles Machines d'inspection Ligne de production non tissée Machines de fabrication de sacs en papier Machines de fabrication de sacs plastiques Fendeuses et rembobineuses Machines de fabrication de sacs tissés

-

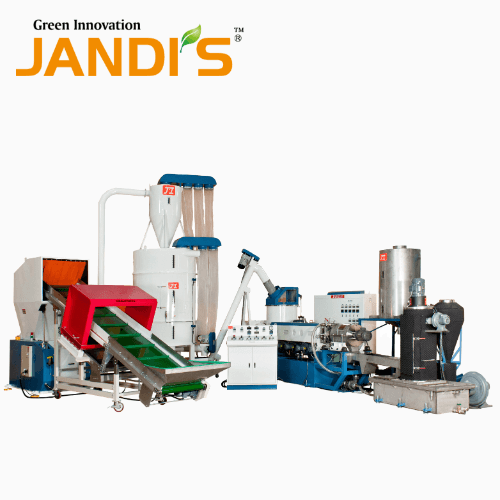

Machines de Recyclage et de Traitement des Matières Plastiques

Lignes de recyclage de bouteilles Classificateurs et systèmes de dépoussiérage Lignes composées Granulateurs Ligne de fabrication de mélanges maîtres Machines de traitement des matériaux Mélangeurs et mixeurs Autre Concasseurs en plastique Machines de granulation en plastique Broyeurs Ligne de lavage en plastique Machines de recyclage des déchets plastiques

-

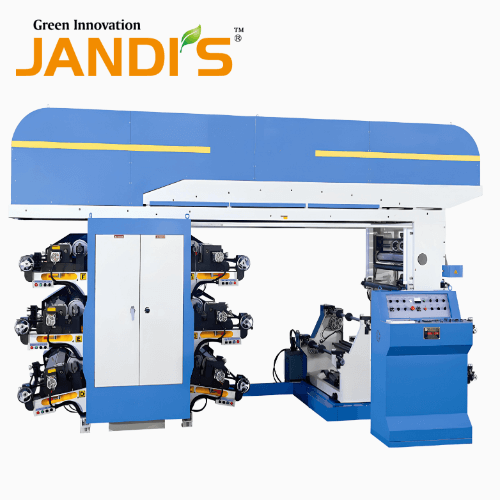

Machines d’Impression

Machines d'impression flexographique Machines d'impression par transfert de chaleur Machines d'estampage à chaud Machines de transfert hydrographique / d'eau Machines d Machines d Machines de tampographie Machines de séchage d Machine d'impression de profil en PVC Machines d'impression par héliogravure Machines d Machine d'impression de sacs tissés

-

Matières Premières et Additifs

Résine ABS Additifs Alliages Résine ASA Matériau composite Plastiques techniques Résine HDPE Résine LDPE Mélanges maîtres Autre PA (polyamide) / nylon Résine PC Résine PE Résine PET Résine PLA Résine PP Résine PS Granules de plastique recyclé Caoutchoucs / caoutchoucs synthétiques Produits chimiques spécialisés Résine synthétique Résine thermodurcissable TPE (élastomère thermoplastique) TPR (caoutchouc thermoplastique) TPU (polyuréthane thermoplastique)

-

Machines de Traitement du Caoutchouc

Machine de moulage par injection de bakélite Machines à calandrer / broyeurs de malaxage Machines de moulage par compression Pétrins à dispersion Machines de refroidissement en caoutchouc Machines de polymérisation / vulcanisation du caoutchouc Machines de découpe de caoutchouc Lignes d'extrusion en caoutchouc Machines de moulage par injection de caoutchouc Mélangeurs en caoutchouc Machines de recyclage du caoutchouc Machines de moulage par injection de silicone

-

Machines de Fabrication de Chaussures

Machines de moulage par injection de bottes de pluie Machines de moulage par injection de chaussures de type rotatif Machines à fabriquer des sandales Machines de moulage par injection de chaussures Machines de fabrication de semelles de chaussures Pantoufles faisant des machines Machines de fabrication de chaussures de sport

- Machines de Thermoformage

CATÉGORIES

-

Équipement Auxiliaire & Automatisation Intégrée

Machines de découpe | Machine de découpe de manche de tambour | Machines de découpe hydrauliques | Machines de découpe d'étiquettes | Machines de découpe d'emballage | Rouleau de papier à la machine de découpe de feuilles | Machine de découpe de sacs tissés en PP | Sheet Cutting Machines | Machine d'en-tête de bouteille |

-

Machines de Moulage par Soufflage

Co Machine de moulage par soufflage d'extrusion | Machines de moulage par soufflage entièrement automatiques | Machine de moulage par soufflage d'extrusion pneumatique | Rouler sur la machine de fabrication de billes creuses | Machines de moulage par soufflage semi-automatiques | Machine de moulage par soufflage |

-

Extrudeuses et Lignes d'Extrusion

Machine à film soufflé PLA/PBAT biodégradable | Machine de film soufflé de sac de vêtement | Mini machine à film soufflé | Extrudeuses de film soufflé multicouche | Extrudeuses de film soufflé à une couche | Machine de film soufflé en plastique | Machines de gonflage en plastique | Machine à film soufflé soluble dans l'eau PVA | Machine de soufflage de film étirable | Machine de film soufflé par sac à fermeture éclair |Machines de fabrication de fils plats | Lignes de production de fils entièrement orientées | Machine de fabrication de tissu soufflé par fusion | Lignes d'extrusion de monofilaments | Machine à monofilament en nylon | Machine de fabrication de corde PP | Machine à monofilament à fermeture éclair |Ligne d'extrusion de feuilles ABS | Machines de fabrication de membranes agricoles | Machines d'extrusion de panneaux | Lignes d'extrusion de film de coulée | Film de coulée de co-extrusion | Ligne d'extrusion de feuilles HIPS / PS | Lignes d'extrusion de feuille de profil creux | Machine de fabrication de feuilles | Machine de fabrication de fichiers de papeterie | Machine de fabrication de film tubulaire |Machine de revêtement et de laminage | Machine de stratification sèche/humide | Machines à plastifier à sec | Revêtement et laminage en ligne | Machines de stratification à base de solvant | Machines de stratification sans solvant | Machines à plastifier humides | Machine tissée de stratification de sac/papier |

-

Produits Finis / Semi-finis / OEM / ODM

-

Machines de Moulage par Injection

Machine de moulage par injection verticale entièrement électrique | Machines de moulage par injection verticales à serrage horizontal | Machines de moulage par injection verticales à table rotative | Machine d'injection d'appâts en plastique souple | Machine de moulage par injection rotative de barre de liaison | Machines de moulage par injection horizontales à serrage vertical | Machine de moulage par injection verticale à serrage vertical |

-

Moules et Filières

-

Machines d’Emballage

-

Pièces et Composants

Crépines |Vis d'extrudeuse | Baril de moulage par injection | Vis de moulage par injection | Vis et baril pour le moulage par soufflage | Vis et baril pour machines à film soufflé | Vis et barils pour moulage par injection | Vis et baril pour extrudeuse de profilés | Vis et baril pour injection de caoutchouc | Vis et baril pour extrudeuse de feuilles et laminage | Vis et baril pour extrudeuses doubles | Vis et baril pour la machine de granulation de recyclage des déchets de plastique | Vis pour machine de moulage par extrusion |

-

Machines de Conversion du Plastique

Machines de fabrication de sacs agricoles | Machine de fabrication de sacs de courrier/cargo | Machine de fabrication de sacs à fleurs | Machine de pliage triangulaire | Machine de fabrication de sacs à vêtements | Machines à fabriquer des gants | Machine de fabrication de sacs à linge | Machines de fabrication de masques | Machine de fabrication de poche pour carte de visite | Machine de protection de feuille | Machines de fabrication de sacs pour t-shirts | Machine de fabrication de couverture de table |Machine de fabrication de sacs en rouleau | Machine de fabrication de sacs | Machine de fabrication de sacs en plastique biodégradables | Machines de fabrication de sacs à joint inférieur | Machines de fabrication de sacs à joint central | Machines de fabrication de sacs à ordures | Machines de fabrication de sacs géants | Machines de fabrication de sacs perforés | Machines de fabrication de sacs en plastique | Machines de fabrication de sacs à joint latéral | Machines de fabrication de sacs à valve | Machine de fabrication de sacs à fermeture éclair/sacs à poignée |Machine de refendage et de rembobinage de rouleaux de papier | Machine de perforation et de refendage | Inspection de la rembobineuse | Enrouleurs | Machine à refendre en caoutchouc | Rebobineuse-refendeuse sans arbre | Inspection de la découpeuse | Coupeuses | Coupeuses pour fil plat | Machine de rembobinage de film étirable | Machine de torsion de ficelle |

-

Machines de Recyclage et de Traitement des Matières Plastiques

Mélangeurs gravimétriques | Mélangeurs de matériaux / Mélangeurs | Mélangeurs de granulés en plastique | Équipement de mélange de caoutchouc | Mélangeurs statiques | Mélangeurs verticaux | Mélangeurs volumétriques | Mélangeur de déchets en plastique | Mélangeur de refroidissement WPC | Mélangeurs WPC |

-

Machines d’Impression

Machines d'impression flexo de type CI | Machines d'impression flexo en ligne | Machine d'impression flexographique de sacs géants | Mini machine d'impression flexo | Machine d'impression flexographique de type hors ligne | Machine d'impression flexo bobine à bobine | Machines d'impression flexo de type pile |

-

Matières Premières et Additifs

-

Machines de Traitement du Caoutchouc

-

Machines de Fabrication de Chaussures

-

Machines de Thermoformage