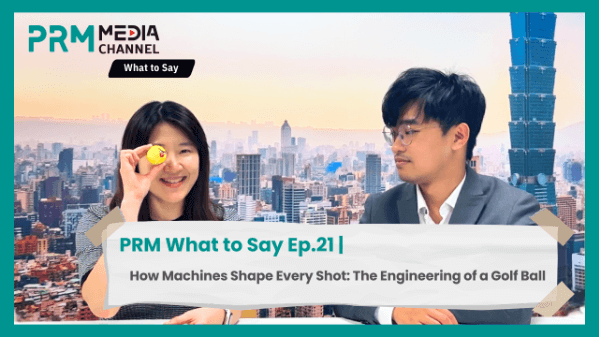

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

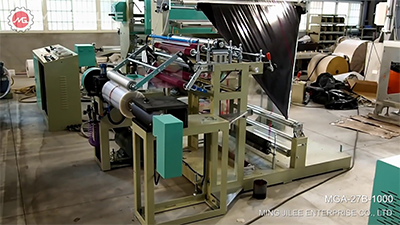

Triangle Folding Machine & 1 Color Rotogravure Printing Machine | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000, MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Air Bubble Film Extrusion Line - CHI CHANG

Air Bubble Film Extrusion Line - 2.5M Wide 3-layer Air Bubble Sheet Extrusion Line The 2.5M Wide, 3-layer Air Bubble Sheet Extrusion Line produced by Chi Chang Machinery Enterprise Co.,LTD has excellent quality and an outstanding reputation. The Air Bubble Film Extrusion Line includes Take-off unit & winder, In-line lamination, T-Die & laminating unit and EPS/EPE reclaim system.

Turkish Plastic Market Evaluation | PDA GLOBAL Interview (POLYSTAR Agent)

PRM Media Channel continues to share with you the most current industry insight into local markets around the world. This time our guest of PRM Industry Insight program is Mr. Emrah Cakir from PDA GLOBAL company, as well as the agent of POLYSTAR in Turkey. We have touched on many current topics of the plastics machinery industry including the shipping obstacles, current plastic packaging machinery demand of the Turkish market due to emerging needs, advantages of having a local agent in the Turkish market, the fluctuation in the foreign currency in the Turkish market, and so on. Let's take a look at the video and hear more from Mr. Cakir about his solution suggestions to the current issues in the market. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

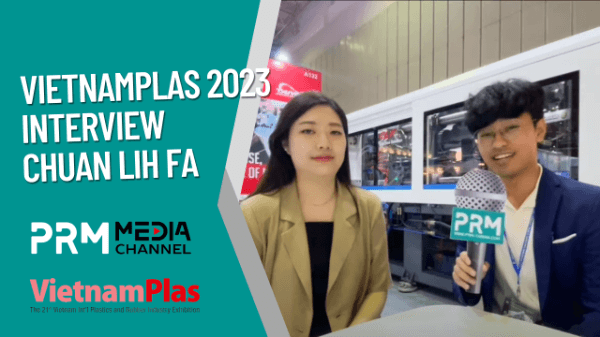

2023 VietnamPlas Interview | CLF

It's our great honor to interview Jenny from CLF, introducing their injection molding machine TWII 250.

CHINAPLAS On-site Tour Hall No.1-6 | PRM-TAIWAN

Hello everyone! It's been a long time since last CHINAPLAS Let one of partner from PRM—— Joey Show you all the fantastic things at CHINAPLAS Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

GENIUS MACHINERY: Innovation & Current Situation in the Plastic Recycling Industry

We are very excited to announce that we have published a Live stream with GENIUS MACHINERY CO., LTD. on October 16th, 21:00 (GMT +8) . Mr. Peter Tsai, General Manager of the company will be our guest that we are expected to have the latest insight from the industry. It was a great opportunity to understand more about one of the main players in the Recycling industry in Taiwan. We covered different topics such as company introduction but also the general introduction of their products, including their Plastic recycling machines, plastic washing plants, pelletizing systems, drying machines of plastic washing lines, and also their shredders and crushers. Within their items will also explain their KRIEGER-Series that are cutter compactor recycling machines, RECO-series recycling machines with side force feeder, and DW-series squeeze dryer. During this 2020 year, one of the main highlights has been the up and down and uncertainty for the Plastics industry, Mr. Peter will explain to us all the different ways they have been doing to overcome a variety of challenges, such as many methods to maintain close interaction with the customers.

Calcium Carbonate Compounding Pelletizing Plant | GENIUS

Calcium Carbonate Compounding Pelletizing Plant-Genius Specializes in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant, GENIUS MACHINERY CO., LTD. was established in 1992, professional in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature Applicable materials For PP、LDPE、PS. For adding in plastic product production; maximum caco3 up to 80%~90%. • Save cost, reduce expenditure, strengthen competition. • Pellet is round and flat in shape, smooth feeling, well plastified, good dispersibility. • Easy operation

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com [email protected]

TaipeiPLAS 2022 Live | PRM x KAOLU x PIDC

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 9/30(Fri.) 15:00 (GMT+8) 【KaoLu Enterprise】 Kao Lu Enterprises Co. Ltd., established in 1980, has been dedicated to manufacturing and supplying premium quality pneumatic components such as valves, cylinders, and ancillary accessories. 【Plastics Industry Development Center | PIDC】 What's the key role that PIDC plays in Taiwan society and how they provide services to plastics manufacturers. By interviewing General Manager of Dr. Hsiao, he would share the insight of SDGs, 2050 Net Zero programme, and also provide advice to Taiwanese enterprises.

Interleaved Draw Tape Bag On Roll Converting System ft. Labeling Device | LUNGMENG

【Feature】 High-speed servo-driven system Special sealing system, keeping the production speed steady regardless of the film thickness and length Convenient sealing knife system, with easy changeovers of sealing knives, making production more flexible Unique perforating knife system for various film materials Intellectual rotary interleaved winder with the 2-in-1 system applicable to bags on roll and interleaved bags User friendly touch screen control system Reliable & multi-functional system, capable of producing star sealed bags, wave type bags, table covers and many more through modular system changes 【Company Introduction】 Lung Meng Machinery also known as Dragon Plastic Machinery was established in 1976 as a professional plastics converting machinery manufacturer. In 1983 Dragon Plastic developed “All In Line System”, which allows blown film extruders, printers and bag machines to work together in-line. Lung Meng Machinery's wide range of innovative machines are the very solution to exceed customer's expectation at a satisfactory price. After 46 years of continuous research and development, Dragon Plastic has become the only company that can integrate all three kinds of machines together in an in-line process.

PRM-TAIWAN @ CHINAPLAS 2021 | Exhibition Opening

PRM Media Channel is happily reporting from CHINAPLAS 2021! In recent years many exhibitions have been canceled or postponed. Despite the COVID-19 pandemic, by implementing strict safety regulations, CHINAPLAS opens its door today once again to assist many exhibitors and the visitor to cultivate plastics and rubber industry. There will be many on-site and online activities expected to take place concurrently. Stay tuned to PRM Media Channel and PRM-TAIWAN B2B platform to gather more insight into CHINAPLAS 2021 activities. We will be posting more content and news about the event.

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

Quick Mold Change - Clamping System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Seaming Machine | WEBCONTROL

Seaming Machine-300(K2)-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

Shanghai World of Packaging (swop) 2024

Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd. will join hands to present the Shanghai World of Packaging (swop) from 18th to 20th November 2024 at Shanghai New International Expo Centre (SNIEC). As a member of the interpack alliance, in addition to continuing to exhibit the packaging industry chain, swop will discuss industry-leading keywords with packers, brands, OEM/ODM, including lightweight, light assets, youth, intelligence, personalization, new materials, new technologies, sustainability, new design trends and other popular topics, sharing packaging cutting-edge concepts and technologies. From materials, equipment, and products to design and marketing, swop is definitely your 360° solution provider in the packaging industry! Find out more at https://adlnk.cn/A3Qm7K5

SIAF 2021 Guangzhou Exhibition Opens Door | PRM-TAIWAN

【 PRM-TAIWAN on SIAF Guangzhou 2021 Exhibition 】 Info: Great news for PRM-TAIWAN, Taiwanese Suppliers, and all the buyers who have put their trust in us! Despite COVID-19, we are glad to announce that thanks to our branch office in China, PRM has come back to the international exhibition ground to do what we do best - Provide professional services to international buyers! PRM-TAIWAN Plastics and Rubber B2B Platform: https://bit.ly/377P7Vv To keep updated about the latest news of the Plastics and Rubber Industry, please follow us on our Social Media Channels: PRM-TAIWAN Facebook: https://www.facebook.com/PRMTAIWAN PRM-TAIWAN LinkedIn page: https://www.linkedin.com/company/prm-taiwan/

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

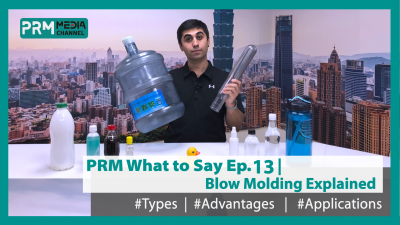

Plastic Blow Molding Process Explained | PRM What to Say EP 13

In blow molding, hollow plastic components are formed through a producing process categorized into three main methods: injection, extrusion, and injection stretch blow molding. In this episode of PRM What to Say, the plastic blow molding process is explained. Besides, we also mentioned some common benefits of the blow molding production method. For more info and machine manufacturer info, you can refer PRM-TAIWAN Blow Molding Machine category at Blow Molding Machine Category Since blow molding allows freedom for design and engineering, the range of applications that you can manufacture by blow molding is really wide. The automotive industry, Appliance components, Medical supplies and parts, Children’s toys, Packaging, Sporting Goods, and Industrial bulk containers are where we see blow molded products often. The blow molding process is very suitable for automation. Especially using the robot technology for take out units and packaging offers the benefit of faster production. Besides that, you can also reduce labor costs by using automation.

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

sleeve seaming machine | WEBCONTROL

sleeve seaming machine -K1-SEAM200-Webcontrol - shrink sleeve seamer Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

Injection Molding Process & Benefits | PRM What to Say EP10

Have you ever wondered how daily used plastic materials are made? Plastic materials are a part of our everyday life. Many of them are made by Plastic Injection Molding process. Starting from toothbrushes, cups, plates, automobile parts, hand tools, electric and electronic hardwares, and so on. So, why is plastic injection molding commonly used for plastic materials manufacturing? We answered these questions and listed 6 benefits of the plastic injection molding process for you. Come take a look at the video to discover more about the plastic injection molding machines and production process.

High Speed Co-Extrusion Coating and Laminating Machine WCL-H-1300| WORLDLY

High Speed Co-Extrusion Coating and Laminating Machine WCL-H-1300 (300 m/min) WORLDLY In this fast-changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds of resin or more by two or more extrusion units to create multi-function extrusion layers. The variety of resin after melted and go through the feed block then join into the T-die. The side screw has corrosion resistance treatment. It’s fine to work with acid copolymer resin, such as EVA, EAA, EMAA, and Surlyn, etc. The barrel heated by a ceramic heater to ensure more energy-saving and short start up time. Worldly also developed the exclusive extrusion output control system with Germany leading dosing system company. So it provides the very accurate and stable output and coating gauge control during the production. It can save more material especially for the long run jobs. The high-speed H series version of the rewinding splicer adopted with a tracking roller device. It provides two kinds of gap & contact winding mode and gives a uniform and perfectly straight finished winding during high speed running. Also the taper tension can properly control the winding from the beginning roll. So it can reduce the wastage and avoid the wrinkle generate at the inner roll. Worldly utilizes only high quality imported T-dies and maintains a ±3% thickness variation. The inner deckle system is customized in-house to reduce trim and provides uniform high-speed production.

2022 Intelligent Asia - Smart Mold, 3D Printing, Logistics & IoT | PRM Exhibition Tour

Let's PRM take you to the on-site through our online touring video!! In the video, you will be showed the advance technology of 3D printing, application of IoT in logistics and high quality of smart mold & die. 2022 Intelligent Asia has 9 major manufacturing sectors that includes Automation, Robots, Logistics, Cold Chain, 3D Printing, Molds & Dies, Laser, Fluid Power, and Smart Machinery.