2024 Expo Plasticos Guadalajara | Organizer Executive Jeorge

Dive into our exclusive interview from the Mexico Plastics and Rubber Industry Expo 2024, where we explore the event’s commitment to sustainability and circular economy practices. This year’s expo features 100% recyclable carpeting, aligning with ESG goals and showcasing the industry’s push toward a greener future. The event has attracted numerous professional buyers, with a bustling atmosphere fueled by nearby factories and industries in Guadalajara. Join us as we uncover the organizers’ objectives and hopes for this year’s exhibition. After watching, visit our PRM platform for a comprehensive post-show report to see if these goals were met. Don’t miss out on the highlights and insights from one of the industry’s most vibrant events!

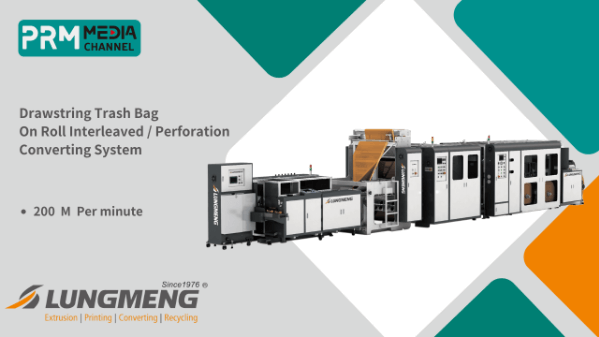

ELS High Speed Rotogravure Printing Machine | WORLDLY-

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY Machine Specifications - Max machine speed: 350 m/min - Web width: 1000 / 1200 / 1300 mm - Printing cylinder circumference: 350 - 900 mm - Material diameter: 800 / 1000 mm - No. Color: 10 colors

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine. Email: [email protected]

Turkish Plastic Market Evaluation | PDA GLOBAL Interview (POLYSTAR Agent)

PRM Media Channel continues to share with you the most current industry insight into local markets around the world. This time our guest of PRM Industry Insight program is Mr. Emrah Cakir from PDA GLOBAL company, as well as the agent of POLYSTAR in Turkey. We have touched on many current topics of the plastics machinery industry including the shipping obstacles, current plastic packaging machinery demand of the Turkish market due to emerging needs, advantages of having a local agent in the Turkish market, the fluctuation in the foreign currency in the Turkish market, and so on. Let's take a look at the video and hear more from Mr. Cakir about his solution suggestions to the current issues in the market. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

Cutter Compactor Plastic Recycling Machine - KRIEGER Series | GENIUS

Machinery in the Video: GENIUS KRIEGER Series - KR-125 Cutter Compactor Recycling Machine [VIDEO HIGHLIGHTS] 0:00 Plastic Recycling Machine - KR-125 0:28 Belt Conveyor 0:41 Cutter Compactor 1:00 Main Extruder 1:11 User-Friendly Control Panel 1:26 Dual-Piston Filter 1:36 Die-Face Cutting Pelletizing [KEY FEATURES ] Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc. Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials. High torque precision gearbox. Low noise and steady operation. Die-face pelletizing is expected to reduce manpower costs. The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation. SAVE cost, energy, and time. The single extruder is suitable for clean materials such as injection leftovers and production waste. [COST SAVING] Saves energy cost up to 20% Reduces labor cost as only 1~2 operators are needed to operate the whole plant. [SUPERIOR FEATURES] /Compacting & feeding/ The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity. /Multiple Cooling/ Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. /Flexible Customization/ GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.

2023 IPF Taiwan Manufacturer Interview | WORLDLY

Worldly Industrial is a very well-known Taiwan manufacturer in the flexible packaging industry in Bangladesh. In the interview, Perrys Chang has shared with us how to do business in Bangladesh, we have learnt that the aftercare and maintenance is important as well. She has also shared her observation on the industry after 3 years of pandemic, what policy or changes have Bangladesh made. Let us see the interview to know more about Worldly and how they operate in the flexible packaging market.

CHINAPLAS On-site Tour Hall No.1-6 | PRM-TAIWAN

Hello everyone! It's been a long time since last CHINAPLAS Let one of partner from PRM—— Joey Show you all the fantastic things at CHINAPLAS Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~

Contribution to Circular Economy & ESG Implementation | GEORDING

In recent years, many manufacturers in the plastics industry have been aware of the environmental issues to reduce waste and protect our environment. GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well. Through the interview with the sales manager, Jessica Liu, she expressed the implementation of Reuse, Reduce and Recycle are core concepts to GEORDING. With the Refuse Derived Fuel production line, they could share the idea and provide assistance to lower greenhouse gas emissions. Supporting their customers is the priority of after-sale service. Even though the pandemic has been affecting the world, GEORDING still maintains an excellent relationship with customers by arranging video meetings and providing the service of remote tests. Therefore, they have been awarding the OEM cooperation with a long-term partner in Japan. One of GEORDING’s customers in Japan uses their RDF (Refuse Derived Fuel) to plant vegetables by using their equipment. As a result, we could tell that more and more manufacturers value the sustainability of ESG. 【Video Outline】 00:00 - Introduction 00:39 - Contribution to the circular economy 02:03 - RDF production line for ESG 03:06 - After-sales service for installation & maintenance 04:01 - OEM cooperation 04:39 - R&D developments 06:20 - Customer success stories 07:40 - Closing

2024 CHINAPLAS Interview | ANIPAC

It’s our great honor to interview Mr. Aldimir Torres Arenas from ANIPAC He shared his insight for the China and Mexico market. Check our video for more information!

Second Life to Recycled Plastics | BoReTech

Have you wondered how PET bottles have been recycled? Where do recycled plastics go? BoReTech is a leading company in the plastic recycling industry, who strives to solve plastic waste and give it a second life. With more than 30 years experience in the industry, BoReTech is able to process different materials from different countries and gain know-how experiences. Lately, BoReTech has redesigned their washing line in a smaller footprint, which is 50% less surface area compared to their standard line. Here are four improvements of the latest washing line called ES-process PET Bottle Recycling System. Smaller Foot Print Convenient in Maintenance Environmental Protection and Sustainability Quality Improvements To be a global pioneer in the plastic recycling ingenuity, BoReTech has gradually moved towards the research, development, and design of the all-plastic recycling process. Let's keep our environment in ecological balance and promote global sustainable development. 【Video Outline】 0:00 Reduction of Carbon Emissions 0:52 BoReTech's Plastic Recycling Solution 1:32 Journey to Plastic Recycling 3:11 Development of BoReTech 3:54 Innovation & Integration to meet food-grade demand 4:38 BoReTech PET Bottle Recycling System 5:10 ES-process PET Bottle Recycling System 7:07 Market share of BoReTech in India & Japan 8:51 Service from BoReTech 9:46 Future Development & Mission

2022 Intelligent Asia - Automation Intelligence and Robot | PRM Exhibition Tour

Let's PRM take you to the on-site through our online touring video!! In the video, you will be amazed how automation intelligence and robots applied in machinery to improve the efficiency and production. 2022 Intelligent Asia has 9 major manufacturing sectors that includes Automation, Robots, Logistics, Cold Chain, 3D Printing, Molds & Dies, Laser, Fluid Power, and Smart Machinery.

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Bag Making Automation Solutions at K 2022 | PLAS ALLIANCE

It's such a great honor to interview Eugene Chiu, the Sales Manager from PLAS ALLIANCE LTD. In the interview, he mentioned influences by the pandemic. In the end, he also talked about the trending topics in recent years, for instance, Circular Economy. PLAS ALLIANCE LTD. also has excellent customization ability. They provide customized machinery, especially when their customers are searching for Biodegradable Materials applications.

2024 CHINAPLAS Interview | Shubham Extrusion

We were delighted to have CHINAPLAS at the ETERLONG booth and meet their largest buyer in India for an interview with us. Mr. Nirav Shah shared that 15 years ago, TAIPEIPas found their trusted partner through PRM-TAIWAN

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

Blown Film and Recycling Machines (Chinese Version)- POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, our PRM Director Alice will be carrying the interview with the CMO Mr. David Lo. During the interview, Mr. David Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

6 Colors High Speed Flexo Stack Printing Machine PKF-1000-6 | PRINTPLAS

6 Colors High Speed Stack Flexo Printing Machine PKF-1000-6 | PRINTPLAS The Central Impression drum surface is precisely grinded and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transported and precisely printed. Machine framed with 80MM cast metal plate, provide a very steady, vibration free foundation for the printing work. High sensitive feed in and feed out tension controlling system, incorporated with synchronized motion control to ensure constant tension during printing. Super fine printing adjustment device to secure printing accuracy at each printing station. Long arch drying tunnel with strong blower to ensure drying of ink during high speed operation. Machine controlled by Japan PLC system with full color user friendly HMI. Full servo system with PLC memory module auto printing controlling system can be added to achieve a high level automation. Quick change over sleeve system can be adopted as optional.

PP Woven Automatic Cutting-Sewing (Conversion) Line (CS-series) | BOTHEVEN

*Accurate bag length control by Servo Motor *Gripper bag transfer system, most advanced design *Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap *Union Special Sewing machine customized model available For more information, visit http://www.botheven.com.tw