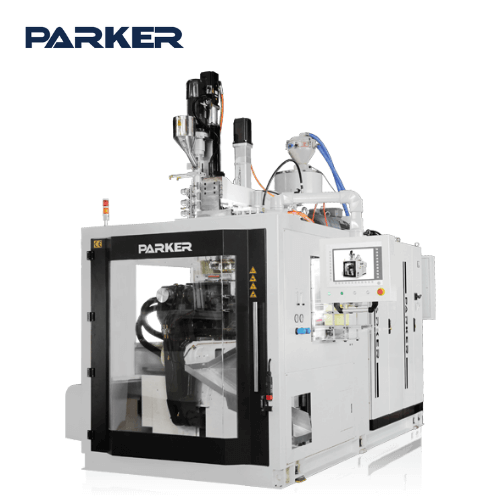

Classification: Machine de moulage par soufflage entièrement électrique / hybride,

Applications:

Agriculture

Toutes sortes de bouteilles et conteneurs

Équipements médicaux

Produits liés à l'alimentation et aux boissons

Mode de vie et cosmétiques

Jerricans

Barils de pétrole / Bouteilles / Barils

Bouteilles de détergent

Bouteilles de lubrifiant

Bouteilles en plastique

Bouteilles de solution saline

Bouteilles de jus

Bouteilles de lait

Bouteilles PET

Bouteilles de Popsicle

Bouteilles de sauce

Bouteilles d'eau/thé

Bouteilles cosmétiques

Pays: Taiwan

Téléphone: 886-4-23396828

Fax: 886-4-23394679

Personne de contact: Joyce Chen

Features for Full Electric Machine

- Stable, precisely, low noise and faster cycle time.

- Lower energy consumption 50~60% compared to equivalent hydraulic machine.

- Improve production efficiency 20~25% compared to equivalent hydraulic machine.

- Electric Parison control with 10~15% lower energy consumption than Hydraulic system.

- Clean and no oil pollution and no oil leaking problem and annoying piping work.

- Extremely low maintenance

Application

|

Dairy |

Jerry Can |

Cosmetic / Personal care |

Edible Oil |

|

Toys |

Lub-oil Containers |

Household Chemical |

Household Chemical |

- Single/Double Station

- Single/Double/Triple/Quadruple..8 Head

- Production volume:2ml~35L

- Multi layers: Co-Extrusion 1-6 layers

- Multi cavities: 1~8 cavities

- Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material

- Special function:View stripe

- Clamping system:Ultra locking system/Toggle/Tie bar

- Driven model: Precision servo gearmotor/Hybrid servo motor drive system/High performance hydraulic power saving system/ close loop proportional valve

- Support full electric/Full hydraulic parison controller/Auto deflashing/Atuo recycling/Auto material feeder/Remote trouble shooting function/IML

| MODEL | UNIT |

PK 45-e/PK 45-H |

PK 55-e/PK 55-H |

PK 70-e/PK 70-H |

PK 80-e/PK 80-H |

PK 95-e/PK 95-H |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material To Be Used | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | ||||||

| EXTRUDER | |||||||||||

| Screw Diameter | mm | 45 | 55 | 70 | 80 | 95 | |||||

| Main Drive | kW | 20HP(15kW) | 25HP(18.7Kw) | 30HP(22.5kw) | 50HP(37.5kW) | 75HP(56kW) | |||||

| Max. Extruding Output/ Per Hour | kgs | 35 | 45 | 70 | 115 | 175 | |||||

| DIE HEAD | |||||||||||

| Cavity number | mm | 1-4 | 1-4 | 1-6 | 1-6 | 1-8 | |||||

| Twin Cavity Center Distance | mm | 80-100 | 80-120 | 80-140 | 80-160 | 80-250 | |||||

| MOLD PLATEN | |||||||||||

| Max. Opening Stroke | mm | 330 | 330 | 410 | 410 | 545 | 545 | 600 | 600 | 700 | 700 |

| Min. Clamping Stroke | mm | 150 | 80 | 210 | 100 | 225 | 140 | 300 | 160 | 350 | 260 |

| Platen Size (W×H) | mm | 320×275 | 320×275 | 460x430(Toggle) | 460×485(Toggle) | 600×485(Toggle) | |||||

| Carriage Stroke | mm | 410 | 410 | 520 | 600 | 720 | |||||

| Clamping Force | kN | 65-85 (Tie Bar) | 65-85 (Tie Bar) | 100-150 (Toggle) | 150-180 (Toggle) | 180- 210 (Toggle) | |||||

* All specifications and designs are subject to change without notice.