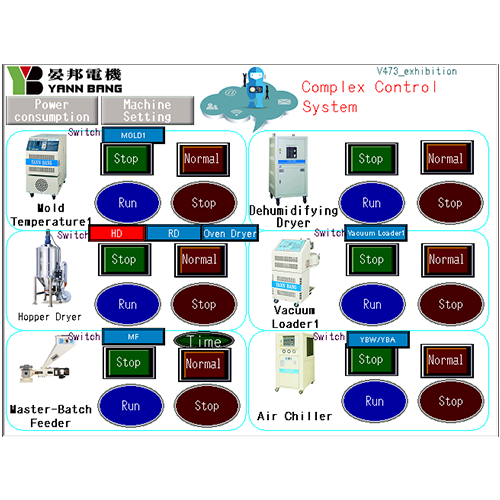

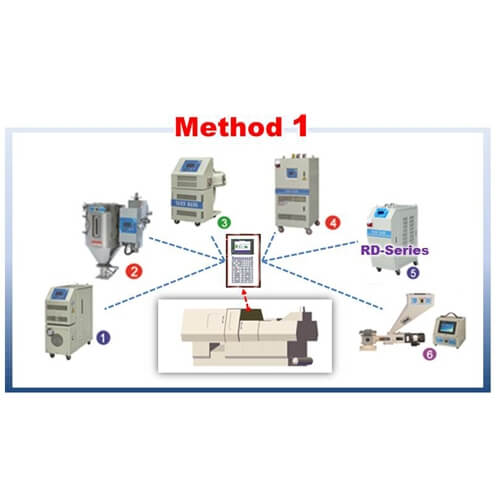

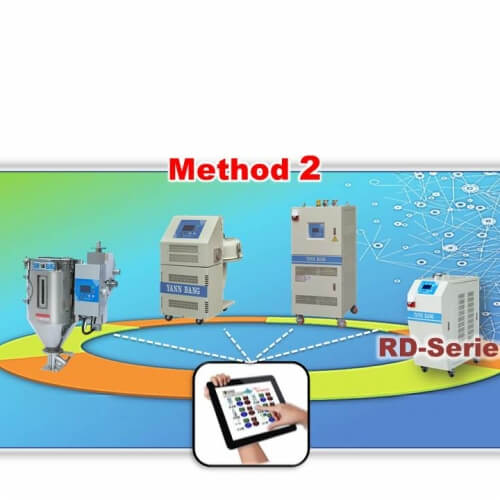

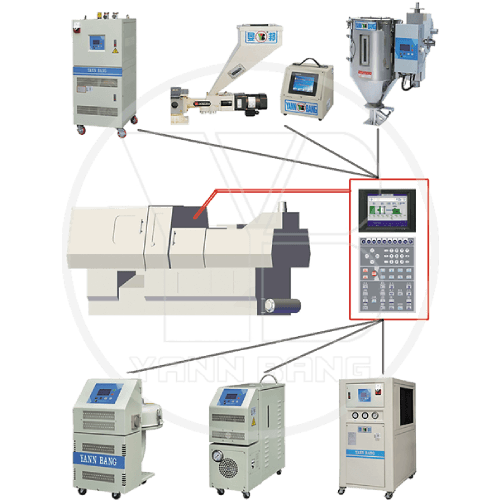

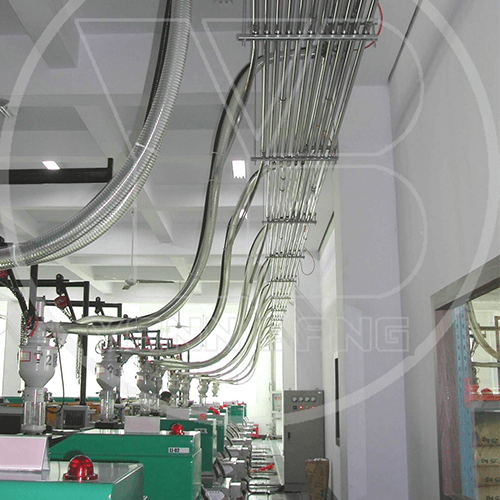

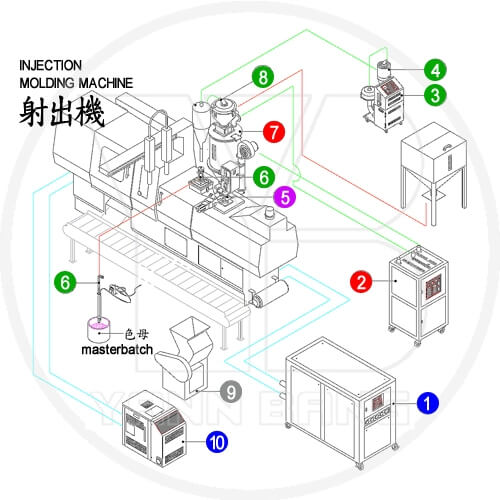

WT(Wise-Transit) Net 4.0

The automatic plastics processing can be controlled by the method of Industry 4.0, Modbus Protocol and RS-485, supplied by Yann Bang, professional experienced programming design and related compatible equipment, to offer you a best solution to a smart factory.

-

Provide the complete production resume for tracking and analyzing.

-

Record the best parameter setting and the experience can be inherited.

-

Machine maintenance can be reffered to and reminded.

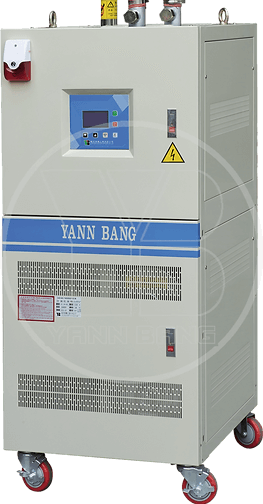

Mold Temperature Controller (YBMI/YBMD)

Steady controlled temperature makes plastic molding accurate in size and consistent with quality. Accurate mold temperature solves the problem of plastic flow patterns, reducing flow and weld lines, gloss appearance, record grooves effect, silver streaking, stress-whitening, warping, and etc....

P.I.D temperature controllers are used for accurate control of temperature within±1℃.

Two-step-heating selector makes rapid temperature increasing possible when require thus saving time and power specially start up in the morning. Patented “Heat-insulated” design improves your safety, extend the machine’s lifetime and make maintenance more efficiently.

-

YBMI : By oil, suit for long-term continuous operation, keep the temperature steady, no flash on tiny and thin products, and no corrosion. However, the heater may be damaged if you do not use the thermo oil correctly or change oil routinely. Recommend to choose oil-type mold temperature controller when your required temperature is 150℃ or above.

-

YBMD : By water, heating up faster, cooling better, harmless to your mold and more economic than oil type for maintenance and cost. However, the water boiling point is low and the element of different water may occur corrosion or limescale to affect the heat exchange and products quality. Recommend to choose water-type mold temperature controller when your required temperature is 150℃ or below.

La trémie isolée unique peut supporter un chauffage répété à haute température. Haute sécurité et bien déshumidifiant. Le poids léger est facile à installer directement sur la machine de moulage. La conception d'une seule unité en acier inoxydable et poli est sans poussière et sans nettoyage.

La conception séparée d'un ventilateur et d'une trémie d'aspiration avec une puissance puissante convient au transport sur de longues distances. Cela éloigne votre résine de la pollution et étend facilement les points d'aspiration pour les besoins futurs.

1. Импортные соты из керамического волокна, превышайте точку росы ниже -40°C осушенного воздуха.

2. Интеллектуальное микропроцессорное управление и защита от перегрева премиум-класса.

3. Точный ПИД-регулятор температуры.

4. Хорошо спроектированное твердотельное реле (ТТР) и защитные устройства.

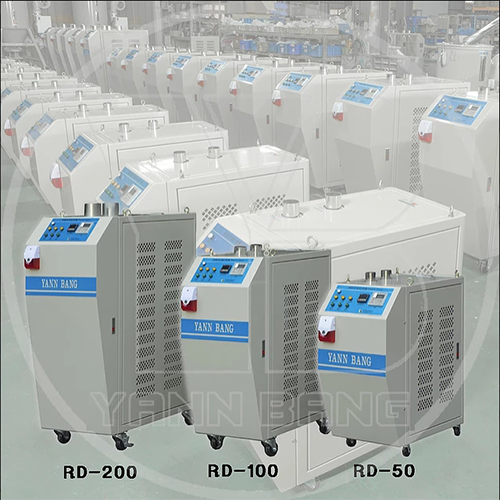

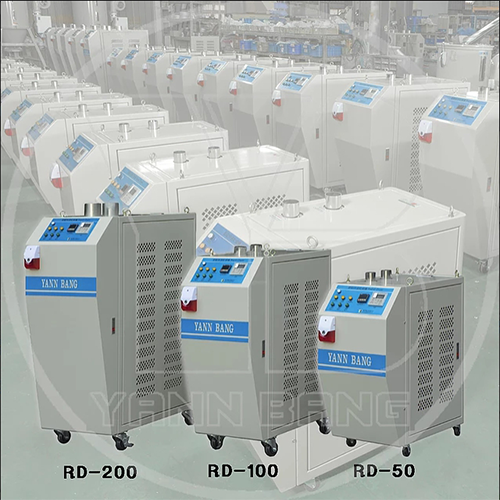

Rapid Dryer (RD)

Without replace your old hopper dryer, use this new dryer to dry faster with better quality and to upgrade production more efficiently.

1. Wide application. Suit to numerous material such as PC, PMMA, PA46, PPS, NYLON and some PET/PETG.

2. Save time and energy. Patented technology significantly shortens the drying time. Normally NYLON takes four hours to dry. Work with Yann Bang’s rapid dryer (RD), it only takes two hours to dry completely and ready to use. RD can decrease 50% of drying hours and save 50% of energy for you.

3. Upgrade energy save. Combine with Yann Bang’s Energy-efficient Hopper dryer can save more energy obviously.

4. Increase yield rate of output. Moisture content can be reduced to 0.02% (depend on the initial moisture content of resin), improve the drying quality of resin, and lower defective products.

5. Easy maintenance. Install with plug-in air filter and dust collector (oil collector) that you can unload easily to clean and replace parts.

Le mélange maître se mélange automatiquement avec votre résine vierge dans la trémie de la machine. Vous n'avez plus besoin de pré-colorer ni de pré-mélanger votre résine. Cela permet d'économiser de la main-d'œuvre, de la résine, des coûts de stockage et de garder l'environnement de travail propre.

L'unité mélange et dose le mélange maître, les additifs, les poudres à écoulement libre, la résine rebroyée et vierge pour assurer un mélange homogène et précis qui se traduit par une meilleure qualité du produit et moins de rejets.