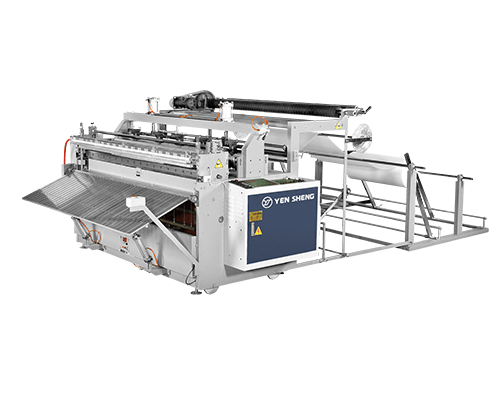

Between two cutting units, there is a 4 m Horizontal roller type conveyor and a 1 m vertical free roller conveyor for carrying and holding the block. When long block is delivered from the transfer conveyor for the two side of vertical cutting unit for trimming long block side skin.

The third set of vertical separator unit can move forward to the middle of cutting station and cut the foam block into half while the conveyor belt is moving forward.

The cutting blade for fourth set of cutting unit is 90° twisted. It can be used as a block cutter for cutting long block into needed size

|

Two side trimming unit |

|

|

Conveyor Working Width |

2200 mm |

|

Conveyor Height |

820 mm ( From the ground to working table ) |

|

Two Side Skin Trimming Working Range |

0 - 12” |

|

Two Side Trimming Height |

1.2 m |

|

Roller Conveyor Length |

2 m |

|

Power require |

Approx.8.2kw |

|

Separator |

|

|

Working height |

1.2 m |

|

Working range |

0 - 1.5 m |

|

Power require |

Approx.4.2kw |

|

Block cut-off unit |

|

|

Working height |

1.2 m |

|

Working width |

2.2 m |

|

Power require |

Approx.5.6kw |