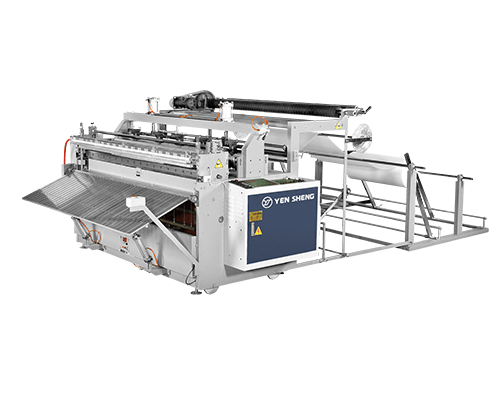

High Torque Cam Drive Mechanism:

Precision processed machine bed offers high accuracy and powerful cutting torque.

Servo Feed System:

Servomotor driven steel feed roller offers precision positioning.

Automatic Stack/Count Function:

Based on quantity setting, automated stacking and discharge functions effectively reduce manpower consumption.

Automatic Mold Release Device:

Servo-driven mechanism ensures fine-tuning position and speed of mold release.

HMI System:

Offers direct parameter setting of 99 functions in the memory.

Waste-Reel Device:

Waste material is automatically reeled, for subsequent chipping on completion of reeling.

Automatic Lubrication System:

Automatic oil feed for slide parts, totally eliminating part failure resulting from insufficient lubrication.

HMI System:

Latest model Siemens control system offers user-friendly operation interface and powerful functionality.

Alignment Mechanism Of Innovative Material:

No wrench or spanner required for adjusting material width; fine-tuning achieved quickly and easily.

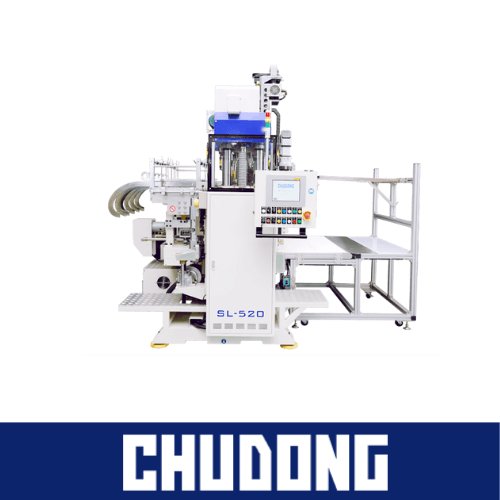

| Model | SL-520 |

|---|---|

| Max. cutting dimensions | 1100 mm × 400 mm |

| Max. material height | 150 mm |

| Max. cutting speed | 100 spm |

| Max. cutting travel | 220 mm |

| Cutting capacity | 8 tons |

| Machine weight | about 7500 kg |

Directly chips waste material, saving space for waste storage as well as manpower for waste material handing.

Photo-Sensor Tracing Function:

Detects material position for carrying out trans-mold hole punch.

Universal Voltage:

Any voltage is available when specified in advance.

CE Certificate.