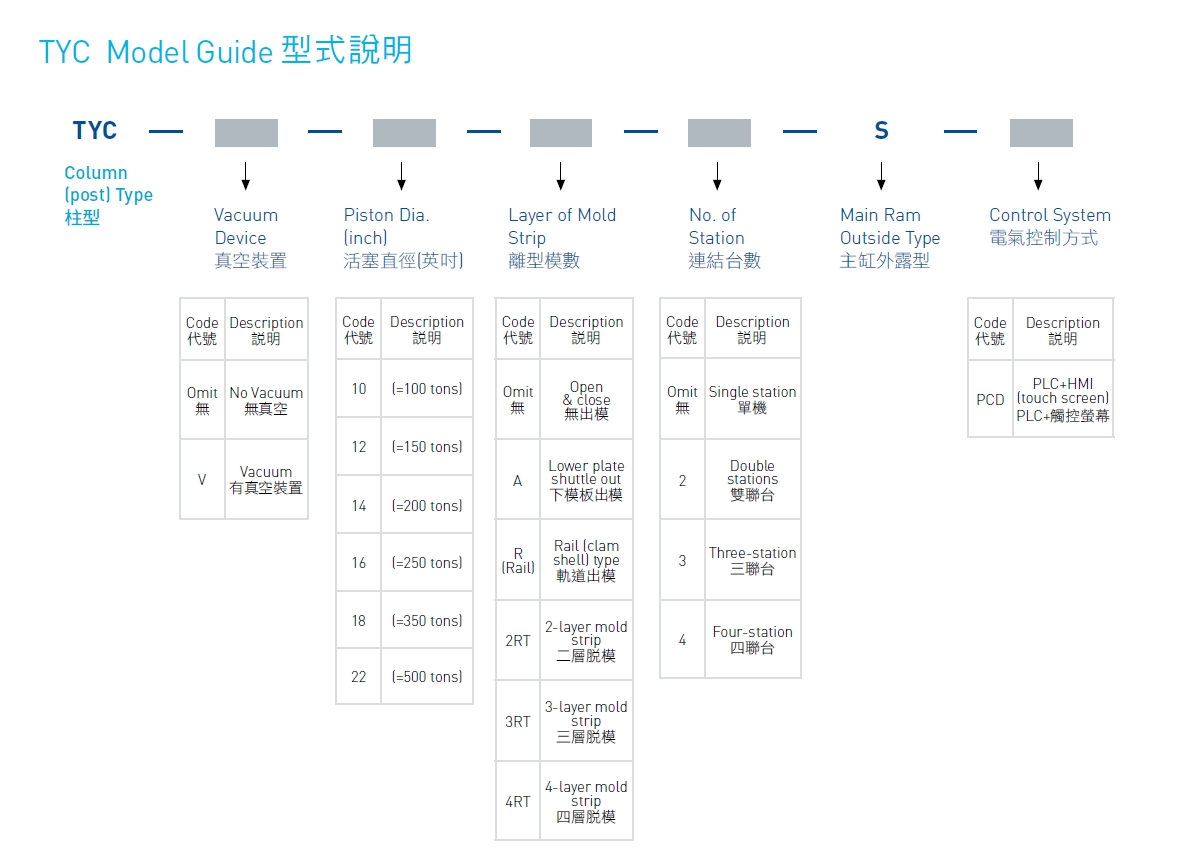

Classification: Machine de moulage par compression (TYC)

Pays: Taïwan

Téléphone: 886-49-2253588

Fax: 886-49-2252998

Personne de contact: Sales Department

- Servo motor drive:Servo press use servo motor as the power source, with transmission mechanism and pressure sensing element to provide the required power for the press, and link the guide screw straight joint press head (or center base) to directly provide the required load for the workpiece.

- Planetary roller screw:Planetary screw uses a roller instead of a ball between the screw and the nut to greatly improve the rigidity and increase the contact area.

- Independent heating platen temperature control system:Provide preheating function before the mold waiting for hot press molding, shorten the hot press molding time and improve the production efficiency.

- Energy saving and environment cleaning:The power consumption rate of the servo motor is more economical than traditional motor with pump design.Without hydraulic system there is no oil leakage and low maintenance.It is suitable for working environments with low pollutions, such as electronics industry, biotechnology industry, etc.

- Precise movement:Control parameters can be input from HMI, and action commands can be issued to driver through PLC and implement servo motor actuation to achieve high-precision control on working force, speed or position performance.

- Complete process setting function:It is convenient for the user to set up process parameters and save portable files as backup.

- Convenient data tracking and statistical result output:The data and graphs of each cycle could be presented as batch statistical information for tracking by operator easily.

- Real-time monitoring of press status:Display of cycle graph and monitoring of press status, sensors and statistics. Real-time production information such as quantity and yield rate to improve the control efficiency and accuracy.

| ITEM | TYC-100-E-PCD-UP | TYC-50-E-PCD-UP | TYC-30-E-PCD-UP | ||||||||||

| Nominal Pressing Force | tons | 100 | 50 | 30 | |||||||||

| Opening/closing speed | mm/s | 50 | 50 | 50 | |||||||||

| Stroke(Adjustable) | mm | 600 | 600 | 600 | |||||||||

| Daylight | mm | 650 | 650 | 650 | |||||||||

| Power | kW | 45 | 20.1 | 16 | |||||||||

| Heating power for each platen | kW | 4.38 | 4.38 | 4.38 | |||||||||

| Heating Platen Size | mm x mm | 400 x 400 | 457.2 x 457.2 | 457.2 x 457.2 | |||||||||

| Working temperature | ℃ | 180 | 180 | 180 | |||||||||

| Position Repeatability | mm | Within +/- 0.01 | Within +/- 0.01 | Within +/- 0.01 | |||||||||

| Data Acquisition Sample Rates | ms | 1 | 1 | 1 | |||||||||

| Machine Size | mm x mm x mm | 1350(W) x 1914(D) x 2969(H) | 1208(W) x 1564(D) x 2739(H) | 1052(W) x 1564(D) x 2620(H) | |||||||||

| Machine Weight | kg | 5240 | 3579 | 3050 | |||||||||

| Screw type | Planetary roller screw | Ball screw | |||||||||||