<•CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. >

• L'application de co-extrusion permet de combiner en une seule paraison des matériaux sans rapport avec des caractéristiques différentes grâce à la tête de filière spéciale Full Shine. Cette combinaison lie différents matériaux, tels que la combinaison de la couche extérieure haute brillance et de la couche barrière par une couche adhésive entre eux afin d'obtenir le résultat parfait. & Nbsp;

• L'application de co-extrusion est la technologie de pointe de la marque leader: Full Shine.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model | FS-40 PSSD | FS-45 PSSD | FS-55 PSSD | FS-65 PSSD | FS-75 PSSD | FS-55 PSSC | FS-65 PSSC | FS-75 PSSC | ||

| Style | Double/single die head/single die holder | Double color/single head single mold frame | ||||||||

| 1 | Use plastic | PE | PE | PE | PE | PE | PE | PE | PE | |

| 2 | Screw diameter | m/m | 40/25 | 45/25 | 55/25 | 65/25 | 75/25 | 55/55 | 65/65 | 75/75 |

| 3 | Screw ratio | L/D | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| 4 | Screw speed | r.p.m. | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 | 15-60 | 15-60 | 15-58 |

| 5 | Inverter motor | HP | 5/2 | 7.5/2 | 10/2 | 15/2 | 25/2 | 10/10 | 15/15 | 25/25 |

| 6 | Pump drive horsepower | HP | 5 | 7.5 | 10 | 10 | 15 | 10 | 10 | 15 |

| 7 | Air compressor with horsepower | HP | 5 | 5 | 7.5 | 7.5 | 10 | 7.5 | 7.5 | 10 |

| 8 | air pressure | Kg/cm2 | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 | 5-7 |

| 9 | Clamping pressure | Ton | 2.8 | 3.9 | 4.4 | 6.9 | 10 | 4.4 | 6.9 | 10 |

| 10 | Fuel tank capacity | Gallon | 38 | 55 | 60 | 80 | 120 | 60 | 80 | 120 |

| 11 | Heating points | ZONE | 6 | 6 | 6 | 7 | 7 | 6 | 6 | 7 |

| 12 | Heating capacity | KW | 9.5 | 12 | 15 | 19.5 | 22 | 19 | 24.5 | 26 |

| 13 | Total power | KW | 19 | 25 | 32 | 40.5 | 44 | 43 | 56 | 77 |

| 14 | Extrusion amount | Kg/hr | 15 | 24 | 42 | 55 | 75 | 42 | 55 | 75 |

| 15 | Empty cycle per hour | time/hr | 1285 | 1030 | 880 | 720 | 650 | 880 | 720 | 600 |

| 16 | Product capacity | c.c./L | 15-500 | 60-1000 | 150-2500 | 1L-5L | 1L-10L | 150-2500 | 1L-5L | 1L-10L |

| 17 | product weight | g. | 5-40 | 10-100 | 20-170 | 40-280 | 80-500 | 20-170 | 40-280 | 80-500 |

| 18 | Maximum and minimum product diameter | m/m | 10-75 | 20-100 | 30-140 | 50-200 | 80-260 | 30-140 | 50-200 | 80-260 |

| 19 | Die mouth diameter | m/m | 50 | 56 | 80 | 150 | 200 | 80 | 150 | 200 |

| 20 | Mold center distance | m/m | * | * | * | * | * | * | * | * |

| 21 | Open and close mold limit | m/m | 50-320 | 50-410 | 140-540 | 160-670 | 50-410 | 140-540 | 160-670 | 160-670 |

| 22 | Die length | m/m | 146-266 | 155-290 | 160-380 | 223-426 | 155-290 | 160-380 | 223-426 | 240-460 |

| 23 | Die width | m/m | 300 | 320 | 360 | 430 | 320 | 360 | 430 | 430 |

| 24 | Machine net weight | Kg | 3300 | 3800 | 4700 | 7600 | 3800 | 4700 | 7600 | 7300 |

| 25 | Machine size | m | 2.6*1.85*2.7 | 3*1.9*2.8 | 3.1*2*2.8 | 3.6*1.6*3.1 | 4.2*1.7*3.2 | 3.1*2*2.8 | 3.6*1.6*3.1 | 4.2*1.7*3.2 |

|

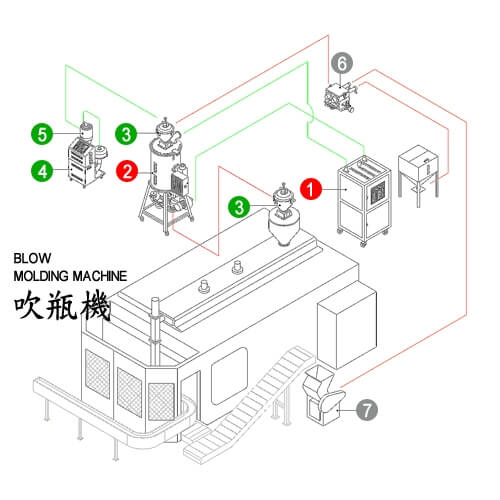

Top view side of co-extrusion 2 layers blow molding machine |

2 layers co extrusion bottles with view stripe line |

Machine photo co-extrusion 2 layers blow molding machine |

2 layers co-extrusion double die head |

|

Blow pin unit |

Barrel and screw set with fans |

2 layers co-extrusion double die head |

Top view side of co-extrusion 2 layers blow molding machine |

|

3 layers co-extrusion double die head |

3 layers co-extrusion double die head with hot cutter |

|

Mask/Closed Wound Drainage Systems |

Household/Cosmetics |

Household/Cleaning product bottle |

|

Household/Cosmetics |

Household/Cosmetics |

Closed Wound Drainage Systems |

|

Toys |

Automotive |

Household/Cosmetics |

|

Outdoor supplies/Bird balls |

Household/Cleaning product bottle |

Agro/ Chemical bottle |

|

Pesticide bottle |

Household/Cosmetics |

Jerry Can Making Machine |

|

Mascara bottle |