2023 VietnamPlas On-site Tour | PRM-TAIWAN

VietnamPlas is an important exhibition in the plastic and rubber industry. Watch the on-site tour video from VietnamPlas for more information!

Five-Layer Extruder & Cutting Machine | BONMART

【Machine Features】 Plastic material has its own characters. In co-extrusion system. BONMART uses and combines several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE) Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc. 【Company Intro】 BONMART offers complete-line including technology transfer, cost analysis, layout, installation, test run, training and satisfactory after sale services. Using our Squeezable PE Tube equipment is the best choice of good investment, Welcome to contact us for more details any time.

Vertical Injection Molding Machine Rotary Table | TAIWAN KINKI

MACHINERY IN THE VIDEO: Vertical Injection Molding Machine -Rotary Table KT 300R 3S FEATURES: -Vertical mold clamping and injection, small footprint, and high degree of precision. This machine is ideal for the injection of medium and small products with inclusions. -The Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. -Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. -Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. -This machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production.

What is Biodegradable Plastic & Bio-based Plastic | PRM What to Say EP9

What are the biodegradable plastics? Are biodegradable plastics recyclable? Are biodegrdable plastics environmentally friendly? What are the types of biodegradable plastics? Where to use biodegradable plastics? We heard your questions and made a research for you, looked for the answers of common questions about biodegradable plastics. We also evaluated difference and similarities of bio plastics and biodegradable plastics. Let's take a look at the video and find out more about these two types of materials!

Plastic Recycling in Japanese Market at K 2022 | POLYSTAR

We were glad to have an interview with Mr. Kenji Murai, agent of POLSTAR in Japan, who shared his observation of plastic recycling in the Japanese market and his experience doing machinery business.

Industry 4.0 Smart Factory for Injection Molding - sFactory 4.0 | SHINI

【VIDEO FOCUS】: SHINI Industry 4.0 Smart Factory for Injection Molding which is called "sFactory 4.0" 【ABOUT SHINI】 Derived from Taipei, Taiwan, Shini group has gone through an extraordinary journey for more than 40 years. To date, Shini group has established six production bases and one corporate technology center globally. Specialized in manufacturing plastic auxiliary equipment, Shini products consist of eight series, including drying & dehumidifying, feeding & conveying, dosing & mixing, heating & cooling, granulating & recycling, automation solution, systematic solution, and hot runner system. Adhered to the management principle “focusing on a particular business, pursuing to be the world leader”, Shini people have created new situations one after another. Till now, Shini group has ranked among the world-class manufacturers of plastic auxiliary equipment and taken the lead of Asia's plastic auxiliary equipment industry.

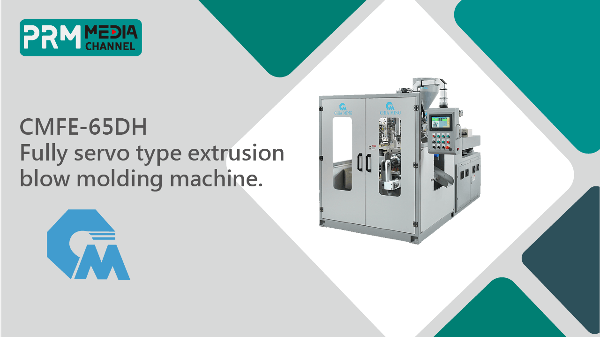

Full Electric Co-EBM with visi strip (4 head double station) | CM-90.55FVH2D | Chia Ming

CM-FE90.55FVH2D Full Electric Co-Extrusion Blow Molding Machine - Continue extrusion with horizontal movement and toggle clamping. Fully automatic and highly efficient production. -------------------------------------------------- Why Go Full-Electric? ► Energy savings 20%~70% ► Precise and more efficiency ► No hydraulic, less noise, no oil leakage ► Easy maintenance -------------------------------------------------- / Key Features / ★ All-electrics (Fully servo motor driven) ★ Servo Drive Die Head Nodding System ★ Full Electric Parison Control System ★ Crank Type Servo Drive Carriage Movement ★ Visi Strip function ★ Auto deflashing device ★ Backhoff, Germany and Keyence, Japan control system -------------------------------------------------- / Other Features / ★ Equipped with robot arm (2D Gripper) ★ Post cooling ★ Auto loading system ★ Residue conveyor to crusher ★ Built by standard components, i.e. Beckhoff, Festo, SMC, Toshiba, Tokimec, Schneider, ABB, Omron, ensuring straightforward maintenance at lower cost and global spare parts availability -------------------------------------------------- / Optional equipment or function/ ????Support the “Industrial” internet of things. (More info, please contact.) -------------------------------------------------- / Application/ Jerrycan/ Food packaging/ drinks/ detergents/ reagents/ cosmetics/ medicines/ engine oil bottles/ lubricants/ jars/ home products/ car parts/ decoration parts...

HDPE Drum Plastic Recycling Machine ft. Chemical Drum Pelletizing System | GENIUS

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor's temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients' needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. 【Company Introduction】 Genius Machinery Co., Ltd. specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipments. Since its establishment, Genius Machinery Co., Ltd. has provided industries with plastic washing lines, plastic recycling machines, pelletizers, plastic squeeze dryers, crushers, shredders, and other complete series of manufacture line for one-stop services.

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

Flexographic Printing Machine | LEEWIN

【Product Lines】 In-line Flexo Printing Machine FSP Off-line Flexo Printing Machine Chamber Dr. Blade Flexographic Printing Machine LL Off-line Flexo Printing Machine Heavy Duty Flexo Printing Machine Logo Flexo Printing Machine Flexographic Printing Machine for Biodegradable Plastic Bag Flexo Printing Machine Opional Equipment 【Company Intro】 LEEWIN brand Flexographic Printing Machines are suitable for reel-to-reel printings of fiber glass cloth, PP/PE woven bags, cellophane, aluminum foil, roller paper, packing paper, tubular films, and PP / HDPE / LDPE / LLDPE polyester bags.

Multi-layers Die Head Manufacturer at K 2022 | HSIN LONG

Hsin Long Thread Rolling Machine Co., Ltd. is knowing for high-quality products, such as blown film machine, extrusion die and extruder filter, and their post-sale service. By interviewing Ms. Sandy Chen, Production Manager, we gained the information about how Hsin Long apply digitalization in their equipment.

Crystallized Hopper Dryer(PET Crystallizer) - Engliish Subtitle | Yann Bang

The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time.

Seaming Machine | WEBCONTROL

Seaming Machine-300(K2)-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

Two Platen Injection Molding Machine - 3500TPII | CLF-

➡️ Maximum injection weight 34 KG. ➡️ High stability, High efficiency, High energy saving.. ➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy. ➡️ Direct pressure clamping to make the mold evenly stressed. ➡️ Smooth, stable and powerful. ➡️ Uniform tension force on tie bars for dramatic increase of service life. ➡️ Simplified construction with no wearing problem on toggle clamp. Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

Label Converting and Finishing System | YICHEEN

Machinery in the Video: Label Converting and Finishing System from YICHEEN Features: * Running operated by full rotary die cut method or intermittent die cut method. * Die is easy in change, save a lot of time in die mold adjustment. * Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession. * Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control. * Sensor detector and alert for broken material to reduce material lost. * Optional module for satisfying customized demands. * Optional Mechanism: EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet * Application: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material, and so on.

MOLD TEMPERATURE CONTROLLER, YANN BANG

YANN BANG, Patented Mold Temperature Controller, Temperature Controlled Unit Our temperature control unit can use water/oil heating system to secure the high quality of plastic production made by injection, extrusion and blow molding machines. Learn more: https://www.yannbang.com/mold-tempera...

Exploring the Future of Packaging Machinery with Thomas Dohse | Shanghai swop Interview

In this exclusive interview at Shanghai swop, we sit down with Thomas Dohse, a key figure from interpack, to dive deep into the future of packaging machinery and the emerging trends shaping the industry. Discover the fascinating highlights of the swop exhibition, including innovative technologies and unique insights into the latest advancements. Thomas also shares his perspective on the resurgence of globalization, which has taken a new form through fragmented and decentralized transactions, creating fresh opportunities for businesses worldwide. Finally, Thomas gives us a sneak peek into the 2026 interpack, unveiling its central themes and what we can look forward to in this global event. Don’t miss this insightful discussion that combines cutting-edge trends with a vision for the future of packaging!

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

Film/Bags Waste Plastic Recycling Machine - KCR-85 | KANG CHYAU

Inquiry and More Info: https://bit.ly/3hVGAvO Introducing the Film/Bags Waste Plastic Recycling Machine from one of the pioneering plastic recycling machinery and film extruder manufacturers in Taiwan, KANG CHYAU. Please click the link above for more information and/or inquiry, which will direct you to the manufacturer. For any assistance, PRM will be more than happy to assist. Contact us through our social media platforms or leave a comment below. Then we will reply and contact you asap. Machinery in the video: Film/Bags Waste Plastic Recycling Machine Model No: KCR-85 Output:80-120 kgs/hr Screw Diameter: Ø 85mm Single Dega Sification Suitable Materials: HDPE/LDPE/LLDPE

Assembling Video of Two Platen Injection Molding Machine - 3000TP | CLF

【ASSEMBLING VIDEO】 Two Platen Injection Molding Machine 3000TP from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance.

Positioning swop as a Packaging Industry Leader: Insights from Adsale’s VP, Rita| Shanghai swop 2024

In my latest interview at swop, I had the honor of speaking with Rita, Vice President of Adsale, one of the key organizers of this impactful exhibition. Rita shared her perspective on how Adsale strategically positions swop as a cornerstone for the packaging industry, fostering meaningful connections and driving innovation. She also revealed Adsale’s core mission behind organizing exhibitions like swop and how they contribute to shaping the future of the industry. Curious about how swop creates value for packaging professionals worldwide and what to expect from this pivotal event? Don’t miss Rita’s insights and her vision for swop’s role in the global packaging ecosystem.

Sustainable Innovation of Blown Film Machine | KUNG HSING-

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy.

K 2022 ON-SITE TOUR | PRM

Can't attend K 2022 in person? PRM will show you the most interesting exhibition highlights on【K SHOW 2022 ON-SITE TOUR】 Taiwanese manufacturers are gathering at K 2022 and showcasing their new technique of plastic & rubber machinery. You can also feel the good vibe from the show. 【Video Outline】 0:00 Introduction 0:16 CHAO WEI PLASTIC MACHINERY | Plastic Converting Machines 0:37 YE I MACHINERY | Plastic Recycling & Material Processing Machinery 1:36 HO HSING PRECISION INDUSTRY | Parts and Components 2:06 HUARONG GROUP | Injection Molding Machines 2:50 SUNKIST CHEMICAL MACHINERY | Thermoforming Machines 3:17 MING JILEE ENTERPRISE| Extruders & Extrusion Lines 3:41 QUEEN’S MACHINERY | Extruders & Extrusion Lines 3:52 CHI CHANG MACHINERY | Extruders & Extrusion Lines 4:17 HSIN LONG | Molds & Dies 4:38 FORMAX | Auxiliary Equipment and Integrated Automation 4:46 YEN SHENG MACHINERY | Extruders & Extrusion Lines 5:01 BOTHEVEN MACHINERY | Auxiliary Equipment and Integrated Automation 5:20 GENIUS | Plastic Recycling & Material Processing Machinery 5:40 JUMBO STEEL | Extruders & Extrusion Lines 6:10 WORLDLY INDUSTRIAL | Printing Machinery 7:00 PRM TAIWAN

Cutter Compactor Plastic Recycling Machine (KRIEGER Series) | GENIUS

The KRIEGER series cutter compactor plastic recycling machine integrates crushing, extruding and pelletizing in one machine. A proprietary designed cutter compactor can compact the density of fluffy plastic film to flakes. It helps to increase the efficiency of extruder. After compactor, the materials are extruded to Genius patented universal joint pelletizing system. The universal joint pelletizing system can automatically adjust the distance when cutting the polymer to pellets. Significantly reduces manual adjustment error rates. After cooling, these pellets are sent to centrifugal dryer to remove moisture. A vibrator at next step removes powders or oversized pellets. Finally, recycled pellets can be reused in different fields, for example, blow film or injection molding industries. / Key Features of Cutter Compactor Plastic Recycling Machine / Energy cost saves up to 20% Only 1~2 operators are needed to operate the pp recycling machine. High-speed rotation operation makes the fluffy material compact. Simultaneous material dewatering. Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The temperature control is convenient, and the temperature of the crushing barrel is controlled in a stable manner. Provide customized recycling, sorting, feeding, degassing, filtering, granulating to storage and packaging systems.

Upstream and Midstream of Taiwan Automation Manufacturing | What To Say EP16

Have you ever wondered why Taiwan is an automation and automotive parts manufacturing stronghold? In this episode, you will be explaining the first two streams, which are upstream and midstream, which are the initial points for the following procedure of the automotive industry.

Injection Molding Machine | CLF

Injection Molding Machine - Chuan Lih Fa Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience. CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

2023 IPF Taiwan Manufacturer Interview | HCI

While at the IPF Bangladesh industry fair, we certainly couldn't miss HCI Industry, which has been operating in the Bangladesh market for many years. This time, Jacky from HCI has shared his point of view on Bangladesh's industry and how Taiwan does business in Bangladesh. We have talked about the differences between the markets in other Asian regions. Let's take a look at HCI Jacky's interview.

Exclusive Interview: Jawhari Kamil on the 20th Saudi PPPP and Vision 2030

Join host Jason as he sits down with Jawhari Kamil, chief organizer of the 20th Riyadh Expo, for an insider’s look at this landmark event. In just a few minutes you’ll learn: What makes the 20th Saudi PPPP and how it reflects Saudi Arabia’s rapid industrial momentum Kingdom Vision 2030 in action—why national transformation goals are shaping every corner of the show Sustainability in focus: from low-carbon solutions to green partnerships that matter A surprise reveal: Jawhari hints at a major collaboration with a world-famous exhibition coming in 2026—watch to the end to find out which one! Whether you work in plastics, packaging, or any sector eyeing the Middle East, this interview delivers fresh insights you won’t want to miss.

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT Originated from the parent company Alfa Auto Machinery Co., Ltd, Gamma is established based on the specific needs of customers. The chairman of ALFA, Mr. Shi Fuxing founded Dongguan Gmtek Technology Limited and Suzhou Gamma Automation Tech Co., Ltd in 2006 with the foundation of 2 million US dollars. The main services of Gamma are precision machining and professionally developed and manufactured high speed vertical machining center. Since the establishment, Gamma strives to fulfill the requirements of the customer and continue to provide the customers with the best service no matter if it’s precision, machining speed , the cost performance or the flatness.

台北包裝展 2023 | PRM 帶看展

TAIPEIPACK 台北包裝展|PRM-TAIWAN 萬眾矚目的台北包裝展來囉! 無法來現場參與的夥伴們,別擔心! PRM這次也為大家準備了帶看展的節目 帶大家一睹展場的熱鬧氛圍!

CHINAPLAS On-site Tour Hall No.7 | PRM-TAIWAN

What! You don't know which manufacturers are participating CHINAPLAS? Hurry up and check out the CHINAPLAS on-site tour brought to you by PRM. Let Alice show everyone the charm of the CHINAPLAS. Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry. ->PRM booth number: 7G01

2022 Intelligent Asia - Automation Intelligence and Robot | PRM Exhibition Tour

Let's PRM take you to the on-site through our online touring video!! In the video, you will be amazed how automation intelligence and robots applied in machinery to improve the efficiency and production. 2022 Intelligent Asia has 9 major manufacturing sectors that includes Automation, Robots, Logistics, Cold Chain, 3D Printing, Molds & Dies, Laser, Fluid Power, and Smart Machinery.

How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry. What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected? Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide. Topics Covered: U.S. reciprocal tariffs overview Strategic moves for manufacturers in 2025 Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

PRM 2021 Market Report through Data Analysis | PRM What to Say EP4

We already left the first half of 2021 behind, it still has been a tough period for many industries including plastics and rubber industry as well. Here, we bring a comprehensive market report through analyzing the data from PRM-TAIWAN B2B platform including global buyer inquiry data by categories. In the fourth episode of the PRM What to Say program Resul, the reporter of PRM Media Channel, invited two of our colleagues from PRM to share their observations of the global market. Daniel is responsible for PRM-TAIWAN B2B Platform which is a marketplace for plastics and rubber machinery, auxiliary and materials. Regarding the platform, Billy is responsible for matchmaking global buyers and Taiwanese suppliers. Through the data we have gathered from PRM-TAIWAN B2B Platform, Daniel and Billy are replying to many different questions that any player of the industry are asking currently. Such as how the situation of the market is, what sub industries are affected negatively and/or positively during the pandemic, what category of the machineries are demanding most for the purpose of what type of applications, and so on. VIDEO OUTLINE 0:00 Highlights in Episode 4 & Video Intro 0:23 Duty of PRM in Plastics and Rubber Industry 1:30 How PRM Market Data is reliable? 2:53 Buyer behavior on PRM-TAIWAN B2B Platform 4:18 Market Insight through PRM Inquiry Data 6:03 Market Demands in the First Half of 2021 7:54 Market Reflection on PRM During the Outbreak 9:50 Video closing Know us more on PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ #PRMMediaChannel #PRMWhatToSay #Inquiry #Data #MarketReport #PRMTAIWAN #Plastics #Rubber #Industry #GlobalMarket #Machinery #B2Bplatform

Plastic and Rubber Industry B2B Platform | PRM-TAIWAN

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers. #PRMTAIWAN

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

Injection Molding Solution | Plastic Injection Molding Machine Manufacturer | CLF

Chuan Lih Fa Injection Molding Machine at steady development of injection molding fields. With strict standards of the quality and the clamping force of the machines, combining high-tech European and Japanese microcomputer controllers, our electric injection molding machine adopts German Siemens controlling system as well as servo motors. The innovative structural design makes Chuan Lih Fa a leader in this industry.

PRM Packaging Theme Pavilion | PRM What to Say EP7

Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event “PRM Theme Pavilion”, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry.

2023 IPF On-site Tour | PRM

IPF Bangladesh 2023 Bangladesh Exhibition covers "three main industries", including plastics, packaging and printing industries, creating opportunities for buyers and manufacturers to communicate with each other! Let PRM Alice show you the IPF Bangladesh 2023 exhibition!

Eco-industrial Chain of Silicon & Semiconductor in Taiwan | PIIF

引言人:國際塑膠工程學會-中華民國總會(SPE-Taiwan)常務理事 邱顯堂 教授 報告人:光宇應用材料(股)公司 何英志 董事長 《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台 塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

Innovative Technique of Environment-friendly Products | PIIF

講者: 華夏海灣塑膠(股)公司 產品研發部 李育奇 課長 《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台 塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

Taiwan’s resource recycling and innovation policy | PIIF

講者:環境部 資源循環署 賴瑩瑩 署長 學經歷:國立成功大學環境工程學系畢業,專職服務於環境部,曾擔任前行政院環保署廢棄物管理處處長暨前資源循環辦公室主任。 自112年9月行政院環境保護署改制為環境部,同時成立資源循環署為三級機關,主責推動「資源循環零廢棄」,目前業務重點為訂定「資源循環促進法」,本場專題演講將著重分享塑膠項目的推動重點。 -資源循環產業的低碳轉型 -推動塑膠資源循環 -循環減碳技術專案分享