Injection Molding Machine | CLF

Injection Molding Machine - Chuan Lih Fa Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience. CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine. Email: [email protected]

Interleaved Draw Tape Bag On Roll Converting System ft. Labeling Device | LUNGMENG

【Feature】 High-speed servo-driven system Special sealing system, keeping the production speed steady regardless of the film thickness and length Convenient sealing knife system, with easy changeovers of sealing knives, making production more flexible Unique perforating knife system for various film materials Intellectual rotary interleaved winder with the 2-in-1 system applicable to bags on roll and interleaved bags User friendly touch screen control system Reliable & multi-functional system, capable of producing star sealed bags, wave type bags, table covers and many more through modular system changes 【Company Introduction】 Lung Meng Machinery also known as Dragon Plastic Machinery was established in 1976 as a professional plastics converting machinery manufacturer. In 1983 Dragon Plastic developed “All In Line System”, which allows blown film extruders, printers and bag machines to work together in-line. Lung Meng Machinery's wide range of innovative machines are the very solution to exceed customer's expectation at a satisfactory price. After 46 years of continuous research and development, Dragon Plastic has become the only company that can integrate all three kinds of machines together in an in-line process.

Film/Bags Waste Plastic Recycling Machine - KCR-85 | KANG CHYAU

Inquiry and More Info: https://bit.ly/3hVGAvO Introducing the Film/Bags Waste Plastic Recycling Machine from one of the pioneering plastic recycling machinery and film extruder manufacturers in Taiwan, KANG CHYAU. Please click the link above for more information and/or inquiry, which will direct you to the manufacturer. For any assistance, PRM will be more than happy to assist. Contact us through our social media platforms or leave a comment below. Then we will reply and contact you asap. Machinery in the video: Film/Bags Waste Plastic Recycling Machine Model No: KCR-85 Output:80-120 kgs/hr Screw Diameter: Ø 85mm Single Dega Sification Suitable Materials: HDPE/LDPE/LLDPE

2023 VietnamPlas Interview | Chan Chao

It's our great honor to interview Tracy from Chan Chao. Tracy also introduced their services in holding worldwide exhibitions.

KAIMEI | PE Extruding Blow Molding Machine for Product Maximum to 1,500L - PBI-1305X-

Kai Mei Plastic Machinery Co., Ltd. established in 1977, is a highly reputed manufacturer of blow molding machines. Different types of machines are designed to produce containers of various raw materials such as PE, PVC, PP, PETG, PU, etc. Kai Mei can produce 5-ml containers of PBA Series Machines to 1,500-liter containers of PBI-X Series Machines. These are fully recognized by customers around the world.

2023 Plastics & Rubber Indonesia On-site Tour | PRM-TAIWAN

Check our on-site tour video for Plastics & Rubber Indonesia 2023! Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

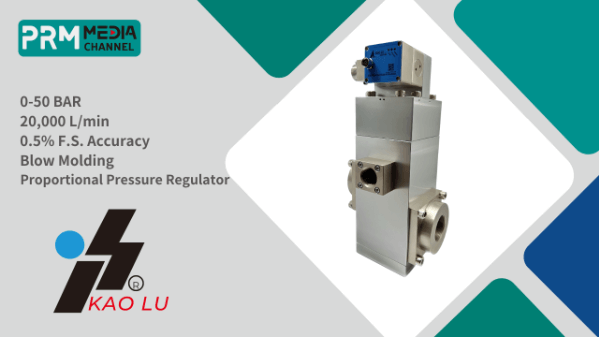

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

HSIN LONG Blown Film Die Heads (Chinese Version) | CHINAPLAS 2021

PRM Media Channel is very glad to announce the great cooperation with CPRJ, the official media group of CHINAPLAS. For this great opportunity, we bring you one of our special actors in the Blown Film Die Head Industry to share with us important facts & insights into the industry, and how their expertise reflects an outstanding performance on customer service, manufacturing process, and quality field. With half a century of rich experience in manufacturing, HSIN LONG is mainly specialized in producing Blown Film Dies and related components. These components can be applied in Packaging Films, Barrier Films for food packaging, Technical Films for high-tech applications, Sealing Films, Agricultural Films, Medical Films, Shrink and Stretch Films, TPU Films, Biodegradable Plastic Bags / Green Plastic Bags, and many more. In this video, our PRM Director Alice will be carrying the interview with the General Manager Amy Lee from HSIN LONG Thread Rolling Co. In the following Ms. Amy Lee will be covering the following topics: 1. HSIN LONG's Mission 2. Market Segmentation 3. Process of Die Design 4. Impact of COVID-19 on Business activities 5. Vision and Future Development 6. Interests on CHINAPLAS 2021

Twin Screw PVC Pelletizing Line | TWIN SCREW

We are a pioneer of twin screw extruder. Description: TWIN SCREW EXTRUDER ⚫With two parallel counter-rotating screws for the palletizing. ⚫Reduction and torque-distribution unit with hardened, ground shafts and gear. ⚫Long service life for the processing units due to lower specific drive energy. ⚫Increased process reliability due to modern control technology. ⚫Easy maintenance and service. DIE FACE CUTTING ⚫Hinge flange type. ⚫High speed rotation of the knives. ⚫Continuous production of granulate. VIBRATION COOLER ⚫Up & Down two vibrating bed. SILO TANK ⚫Stainless steel. Our Service: Technology innovation, perfect service, and internationalization are always our core values, with this mission we have become the pioneer of twin screw extrusion in the global market and a reliable partner of our customers. TwinScrew will never stop progressing in the field of PVC extrusion and twin screw extrusion; we will no doubt lead the twin screw technology into an ultimate and great attainment.

CHINAPLAS 2025 | Innovation and Collaboration for Sustainability

Experience the future of plastics at #CHINAPLAS2025! Shenzhen World Exhibition & Convention Center (Bao'an), Shenzhen, PR China 15-18 April, 2025 Let's embark together on this journey of innovation, collaboration, and sustainability! See you there #PlasticsInnovation #CHINAPLAS

Quick Mold Change System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS. HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

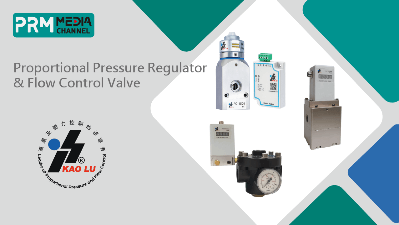

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

Corona Treater | CHAANG HORNG-

.For non-conductive substrates .400~1600mm treat width available .One / Two side treatment .25mm segmented electrode finger .Φ 2.5” treatment roller

【K show 2022】Plastic Bag Making Machine | Bag On Roll Making Machine - PAL

PAL has decades of experience in Plastic Bag Making Machine manufacturing, and continues to develop, manufacture, and sell to all over the world, and even participates in exhibitions around the world.

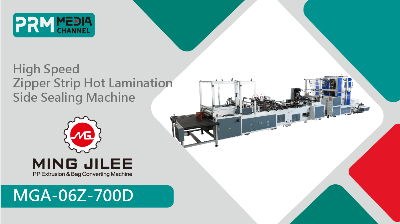

High Speed Zipper Strip Hot Lamination Side Sealing Machine | MING JILEE

【Machine Features】 Taiwan-made and stable PLC controller The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan. Zipper Bag Side Sealing Machine is equipped mark sensor for printed material. For getting the best quality of zipper bag product, unwinding station is mount the auto tension control. The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. Ultrasonic welding is design by motor driven for highest speed production. The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. 【Company Intro】 Ming Jilee Enterprise Co., Ltd. is manufacturing film blowing machinery with materials of PP and LD/HDPE; PP thin and thick sheet making machine; waste recycling and pelletizing machine, stationery making machinery- can produce business file/data bag/file clip/photo pocket/name card pocket/index/bubble paper envelope; sealing & cutting machinery-side sealing bag/t-shirt bag.

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

PP Woven Automatic Cutting-Sewing (Conversion) Line (CS-series) | BOTHEVEN

*Accurate bag length control by Servo Motor *Gripper bag transfer system, most advanced design *Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap *Union Special Sewing machine customized model available For more information, visit http://www.botheven.com.tw

2024 NPE Orlando Interview | WIPA

We are honored to have our first interview with Wipa, a high-quality plastic recycling machine manufacturer from Germany. In this interview, Wipa introduces their latest machine show at NPE, highlighting its features and benefits for the plastic recycling industry. Join us to learn more about this innovative technology and how Wipa continues to lead performance.

Shanghai World of Packaging (swop) 2024

Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd. will join hands to present the Shanghai World of Packaging (swop) from 18th to 20th November 2024 at Shanghai New International Expo Centre (SNIEC). As a member of the interpack alliance, in addition to continuing to exhibit the packaging industry chain, swop will discuss industry-leading keywords with packers, brands, OEM/ODM, including lightweight, light assets, youth, intelligence, personalization, new materials, new technologies, sustainability, new design trends and other popular topics, sharing packaging cutting-edge concepts and technologies. From materials, equipment, and products to design and marketing, swop is definitely your 360° solution provider in the packaging industry! Find out more at https://adlnk.cn/A3Qm7K5

Quick Die Change | FORWELL

Quick Die Change - Quick Die Change System-qdcs-en-Forwell Features : • Decreased die change time • Designed for hydraulic and pneumatic presses • Increased efficiency • Reduced labor costs • Safer operations System Introduction : Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management. Quick Die Change Systems are becoming a standard for large manufacturers as they not only increase production efficiency, but also improve the overall working environment. The Automatic Die Change System can be built specifically for your machining requirements and will drastically reduce machine idle time during die changes, boosting your competitiveness. There are also a number of indirect benefits of installing a Quick Die Change System for your hydraulic and mechanical type press machines. Firstly, automated operations reduce labor expenses, but also reduce workshop accidents and the physical stresses on operators, making them more productive. Secondly, all dies can be changed without any modification allowing for the use of standardized die and press equipment, saving costs. Lastly, multiple presses can share a single Quick Die Change System, further economizing on costs and resulting in higher efficiency and productivity.

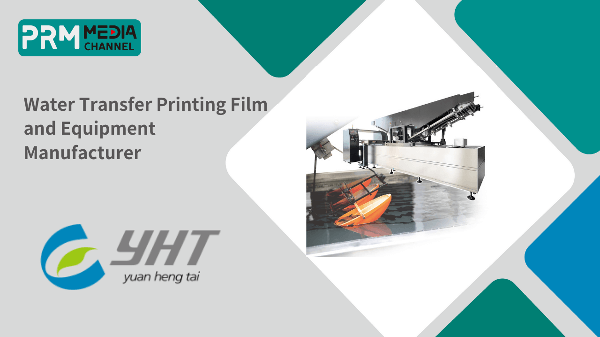

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

GENIUS MACHINERY: Innovation & Current Situation in the Plastic Recycling Industry

We are very excited to announce that we have published a Live stream with GENIUS MACHINERY CO., LTD. on October 16th, 21:00 (GMT +8) . Mr. Peter Tsai, General Manager of the company will be our guest that we are expected to have the latest insight from the industry. It was a great opportunity to understand more about one of the main players in the Recycling industry in Taiwan. We covered different topics such as company introduction but also the general introduction of their products, including their Plastic recycling machines, plastic washing plants, pelletizing systems, drying machines of plastic washing lines, and also their shredders and crushers. Within their items will also explain their KRIEGER-Series that are cutter compactor recycling machines, RECO-series recycling machines with side force feeder, and DW-series squeeze dryer. During this 2020 year, one of the main highlights has been the up and down and uncertainty for the Plastics industry, Mr. Peter will explain to us all the different ways they have been doing to overcome a variety of challenges, such as many methods to maintain close interaction with the customers.

Taiwan Injection Molding Machine | CLF

Taiwan Injection Molding Machine - Chuan Lih Fa Products: plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html

PET Bottle Recycling System and Process for Food Grade Flakes | BoReTech

BoReTech has been a specialized manufacturer focusing on the customized R&D for PET recycling production since 1989. Moreover, the company also has more than 15 years of manufacturing experience. BoReTech provides a total solution of the plastics recycling system, polyester staple fiber production, and many more. In the video, you will find the on-site machine introduction of : PET Bottle Recycling System Process for Food Grade Flakes Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

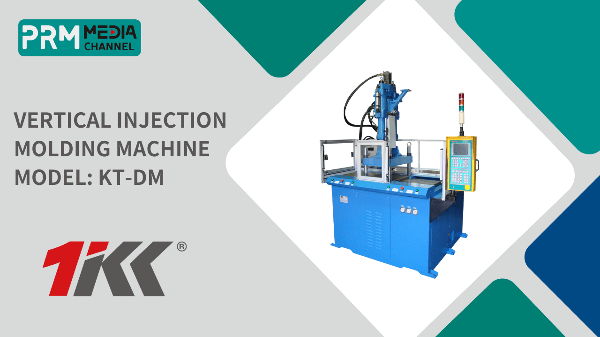

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

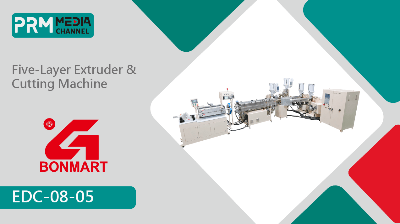

Five-Layer Extruder & Cutting Machine | BONMART

【Machine Features】 Plastic material has its own characters. In co-extrusion system. BONMART uses and combines several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE) Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc. 【Company Intro】 BONMART offers complete-line including technology transfer, cost analysis, layout, installation, test run, training and satisfactory after sale services. Using our Squeezable PE Tube equipment is the best choice of good investment, Welcome to contact us for more details any time.

Plastic Washing Machine | GEORDING

Plastic Washing Machine - Plastic Film Crushing Washing and 3IN1 Pelletizing Line - Waste Plastic Crushing & Washing Line 1000kg - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of Plastic Washing Machine. The main businesses include: Plastic Washing Machine and planning of entire plant’s equipment. While the demand for output and quality in Plastic Washing Machine worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Plastic Washing Machine products and services to higher standards.

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES OF THE MACHINE: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

sleeve seaming machine | WEBCONTROL

sleeve seaming machine -K1-SEAM200-Webcontrol - shrink sleeve seamer Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

2024 TaipeiPlas International Plastics & Rubber Industry Show| Geording

In this video from the 2024 TaipeiPlas International Plastics & Rubber Industry Show, we present Geording’s machine designed to support green policies. With a self-cleaning screen changer, their equipment helps customers enhance efficiency and focus on green recycling development. Geording has maintained a long-term working relationship with Polaris, and we explore their experience with our services. Watch to learn more about Geording's commitment to sustainability in the plastics and rubber industry!

Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

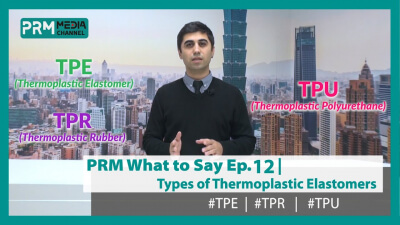

TPE, TPR, TPU Materials Explained | PRM What to Say EP12

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together. 【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers. [TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry. 【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs. [TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more. All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

Injection Molding Solution | Plastic Injection Molding Machine Manufacturer | CLF

Chuan Lih Fa Injection Molding Machine at steady development of injection molding fields. With strict standards of the quality and the clamping force of the machines, combining high-tech European and Japanese microcomputer controllers, our electric injection molding machine adopts German Siemens controlling system as well as servo motors. The innovative structural design makes Chuan Lih Fa a leader in this industry.

Blown Film Machine HDPE LDPE LLDPE (ABA) Two Layer | KANG CHYAU

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance, PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap. Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S SUITABLE MATERIAL: HDPE / LDPE / LLDPE APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on. FILM THICKNESS: 0.010-0.15 mm FILM WIDTH RANGE: 1200 mm FILM OUTPUT: 90-140 kgs/hr

PET Recycling Innovations and Sustainability through Plastic Recycling | PARTICO

This time our guest is Partico Machinery Inc. Partico stands out with its customized thermoplastic recycling machines in Taiwan with over 25 years of experience. Dear Denny Chang and Lucy Huang, the sales representatives of the company, were really intimate to share their company's innovations and investments in R&D. By developing PET vacuum extrusion pelletizing system, Partico makes a distinction from other traditional manufacturers and creates its own market value. As a manufacturer of extrusion pelletizing machines, Partico is dedicated to calling for the importance of sustainability. The purpose of the company is not only to manufacture plastic recycling machines for the industry but also to assist in environmental protection with efficient machinery, as a part of the company's ESG contribution. The most important thing is that Partico is familiar with various materials that its machines can recycle. In addition, Partico is also capable to plan suitable conveyor systems for the customers according to their materials characteristics and applications, so they do not need to worry about the overall planning of equipment. In recent years, the main trend in the PET recycling industry is to apply pellets to make food contact materials. One of Partico's goals is to get FDA certificate, which refers to manufacturing recycling machines that recycle PET flakes for food packaging applications. We have more to share, then let's take a look at this intimate interview and learn more about Partico and its innovative contribution to the plastics recycling industry.

2023 VietnamPlas Interview | CLF

It's our great honor to interview Jenny from CLF, introducing their injection molding machine TWII 250.

JIT-SS |JIT T-Shirt Bag Making Line |JANDI'S

【Machine Features】 Mono-layer, 2+0 printing Power Required Reduced Processing Waste Reduced Production Mistake Reduced CO2 Emission Reduced Total Lead Time Reduced Labor Cost Reduced Recover Die-cut Material Storage Space Reduced 【Company Intro】 JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Plastic Recycling Machine - Plastic Film Squeezing Machine | GENIUS

Plastic Recycling Machine -Genius- Plastic film squeezing machine Specializes in plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. The latest solutions for film washing line If you would like to produce the high quality and validity of pellets, you beware "Squeezing process must be prior to pelletizing process". After plastic recycled film materials are washed, the moisture is usually retain over 30%. Therefore, our superior design team specially developed a squeezer to meet customers’ needs. Through this machine, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders. Speed-changing gearbox We adopt a self-made gear box with high technology precision. Our single screw squeezer is equipped with a gearbox with two-speed derailleurs. According to characteristics of the materials you feed, you can choose which speed you want. You don’t need to buy another squeezer when you feed another kind of materials. It makes the whole washing line more efficient and saves much space. High Productivity Through our dedicated screw design, washed materials can be squeezed to dehydrate water of films or fluffy stuff. The recycled materials you feed are squeezed to become flakes or lumps . The moisture they contain will be lowered down to 1-3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Its output can amount to 700~960kg/hr per hour and the degradation of the pellets will be highly decreased. Furthermore, you don’t need to increase heating rate. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity. Always your best choice Our single screw squeezer can help you SAVE cost, SAVE energy, SAVE time, PROTECT environment, and INCREASE productivity as well as efficiency. It is definite your best choice! You NEVER miss it.

Plastic Recycling and Blown Film Industry in LATAM | RRC Limitada (Polystar's Agent)

Recently, we had an interview with the General Manager and Auditor Accountant of RRC Limitada (Polystar's Chile Agent), a company based in Chile, which supplies South American countries with several kinds of plastics machinery including recycling machines, blown film extruders, bag making machines. They have vast experience knowing the machines and attending international exhibitions, which allow them to have a better understanding of how to assist a customer. RRC Limitada also represents Polystar Machinery, which is a successful Taiwanese manufacturer famous for recycling machinery and blown film extruders lines in many regional markets. Mr. Ricardo Rubilar and his son Rodrigo mentioned how their company's growth opportunities have increased in spite of the devastating impact pandemic has brought to the global economy. In the video, we will see how they explained the importance of having an agent in local markets can give a company greater selling results and enhanced services to local buyers.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Haitian Mexico Interview Part 2 | Solutions for Pandemic and Future Outlook

At the beginning of the month, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! In Part 2 of the video conference the Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the challenges they are having due to the pandemic, their solutions to overcome those challenges, and the current situation of COVID-19 in Mexico.

Calcium Carbonate Compounding Pelletizing Plant | GENIUS

Calcium Carbonate Compounding Pelletizing Plant-Genius Specializes in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant, GENIUS MACHINERY CO., LTD. was established in 1992, professional in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature Applicable materials For PP、LDPE、PS. For adding in plastic product production; maximum caco3 up to 80%~90%. • Save cost, reduce expenditure, strengthen competition. • Pellet is round and flat in shape, smooth feeling, well plastified, good dispersibility. • Easy operation

Bangladesh Culture and Tips on Operating Market | PRM What To Say EP18

Bangladesh has a rich, diverse culture. Its deeply rooted heritage is thoroughly reflected in its architecture, dance, literature, music, painting and clothing. For this episode, we’re going to talk about Bangladesh culture and tips on the operating market. Let PRM Cicilia share her insight and observation about Bangladesh Market!

All electric blow moulding 20L jerrycan energy saving, no hydraulic oil, no pollution, industry 4.0 | FONG KEE

Model No : FK/EHB-55G-100G-55GT20SD Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system.