Automatic Rotary Sealing machine(Bowl/Cup) Manufacturer | ET-80L3D8 | YF-SUPER SEALER | Y-FANG

Y-Fang Automatic Rotary Sealing Machine (ET-80) is designed to provide seamless and efficient sealing for bowls and cups. This advanced machine offers a fully automated process, from product loading to precise sealing, ensuring a secure and airtight finish every time. Its compact design is ideal for businesses seeking to maximize efficiency while maintaining high standards of hygiene and product quality. With easy operation and robust construction, the ET-80 is the perfect solution for streamlined packaging in the food and beverage industry. Application ✔️Suitable for beverages, Pudding, Jelly, Fast-food, Snacks, Various prepared foods for the microwave, Seasoned frozen food, Pickled foods, Seafood, processed agricultural products, etc. Which load into the cup and tray. ✔️Sealable material: PP, PE, PS, PET, HDPE, EPS, PSP, Aluminum foil, Paper box, etc. ✔️For smaller working spaces but higher capacity. Y-fang Group was established in 1985, specialize in the design and manufacture of sealing machines for various industrial applications. With over years of manufacturing experience, we are able to produce a wide range of tray sealing machines with a capacity of 450 to 600 pieces per hour. Our machines can perform a variety of different functions such as auto-dropping, piston filling, date printing, vacuuming, and gas flushing (MAP: Modified Atmosphere Packaging). Furthermore, we are also able to provide our customers with OEM, ODM, and OBM manufacturing solutions. Our products have been exported to countries over the world, including Europe, Asia, Africa, and America.

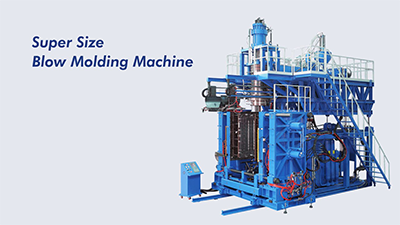

Blow Molding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. [Products List] + Small Blow Molding Machine + Medium Blow Molding Machine + Medium Co-extrusion Blow Molding Machine + Large Blow Molding Machine + Supersize Blow Molding Machine + Double L-Ring Drum Blow Molding Machine + Semi-auto Stretching Blow Molding Machine

5 Gallon PET Preform Turnkey Solution | KING'S SOLUTION

5 Gallon PET Preform Turnkey Solution | KING'S SOLUTION -------------------------------- MANUFACTURER: KING'S SOLUTION CORPORATION MODEL: KPET3200 ------------------------------- SPECIFICATIONS: 700g preform x 8 cavities 90 secs Cycle time 7,200 pcs/day

Bag Making Machines for Multiple Applications | WORLD STEEL

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, World Steel is dedicated to making technological innovations and manufacturing packaging machines. The company has one of the best engineering crews in the industry to provide total solutions which include design, customization, and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self-adhesive bags, handle bags, sandwich bags, or more, then World Steel is one of the best choices for you.

PK-90CSV MHB Single Head Single Station View Stripe Blow Molding Machines | PARKER

Fully electric model machines are available.

PK-95CTS (PE) (Toggle) Single Head Twin Station Blow Molding Machine | PARKER

For more info or Inquiry, please visit PARKER on PRM TAIWAN.

Plastic Bag Folding, Sealing & Cutting Combo Machine

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, they are dedicated to making technological innovations and manufacturing packaging machines. World Steel on PRM: https://www.prm-taiwan.com/shorturl/Qrm7p5Qg

Thermoforming Machine | CHULIING

Thermoforming Machine-Continuous Thermoforming Machine Chuliing Machinery Co., Ltd was established in 1985 and is now an expert in manufacturing Thermoforming Machine. Our products are sold worldwide and we are well-known die cutting machine manufacturer. Chuliing Machinery has a commitment to technological innovation so as to benefit his customers and agents from all aspects. We also dedicate ourselves to develop automatic equipment and to train our employees to further enhance our Thermoforming Machine product quality.

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Accumulator Blow Moulding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. Detail Specifications : The Abl Series Blow Moulding Machines Are Particularly For Producing The Jerry Can/Drum Tank/Large Article Produtions.It Can Be Combined With Some Accessory Equipments To Increase The Efficiency And Expand The Functions, Such As: After Cooling Unit/Auto Deflashing Unit. The Die Head Can Stock The Melting Resin And Purge The Material For Blowing Formed It Designed With Two Heart Flow Chnnels.Can Make Welding Line-Free To Increase The Strength Of Production. The Tie Bar-Less Clamping Unit Is Consist Of Stiffness Structure Frame And Guiding Devices.Make Sure Deflection-Free Advantage. Also Devise With Precision Rack GgearsO of Bboth Side.Make Synchronize Moving Of Plates. The Blowpin Unit Is Designed For Production Calibrating. That Will Be Suited For Different Demand Of Customer. Accumulator Die Head Blow Moulding Machine. GEFRAN CONTROL SYSTEM -PID Temperature Control System (With High/Low Alarm) -Motor PID Feedback Control Function -300 Points Parison Control -PLC Ladder Program Edlitor -Presscription Record Memory Accumulator Die Head Blow Moulding Machine AUTO-DEFLASHING UNIT This Unit Can Be Excuted Top/Bottom/Handle Deflashing Function By Hydraulic And Pneumatic. And Then Used With Suction Device To Take Out And Turn Over The Production.

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer. Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage. The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc. Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.