2023 VietnamPlas Interview | CLF

It's our great honor to interview Jenny from CLF, introducing their injection molding machine TWII 250.

rPET Bottle for Household Packaging Solution | ChumPower

Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries. 【Product Appliance】 Beverages Water Edible Oil Daily-used Cosmetics 【Product Range】 One Stage Injection Blowing Machine Injection and Bottle Molding Manufacturing Stretch Blow Molding Machinery Sales / Turnkey Solution TS Series Models for Lower Production Output (Suggest to new market players) Linear PET Blow Molding Machine (Suggest to buyers who is looking for higher output) 【SS10-rPET Single-stage PET Bottle Blowing Machine】 Hybrid hydraulic system with an optimized clamping mechanism to ensure Energy Efficiency Barrier screw with venting capability can effectively lower the energy required for drying Adopt 4 station design Non-contact feature Reach the trending topics of ESG, Carbon Neutrality, and Net-Zero Emission

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

Blown Film Machine HDPE LDPE LLDPE (ABA) Two Layer | KANG CHYAU

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance, PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap. Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S SUITABLE MATERIAL: HDPE / LDPE / LLDPE APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on. FILM THICKNESS: 0.010-0.15 mm FILM WIDTH RANGE: 1200 mm FILM OUTPUT: 90-140 kgs/hr

Blown Film and Recycling Machines - POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, Daniel from PRM will be carrying the interview with the Chief Marketing Officer Mr. David Lo. During the interview, Mr. Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

sleeve seaming machine | WEBCONTROL

sleeve seaming machine -K1-SEAM200-Webcontrol - shrink sleeve seamer Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

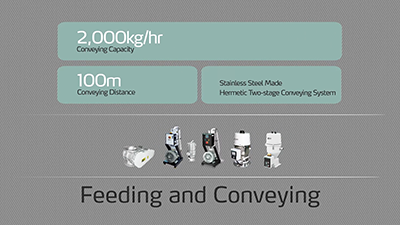

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

Die Cutting Machine Manufacturer | Yicheen

Yicheen High Precision Die Cutting Machine offers a variety of options, such as CCD Auto Positioning, Auto movable Stacking, etc., click the link to see more Die Cutting Machine info: ???? https://bit.ly/3qbjbtf

2023 IPF Taiwan Manufacturer Interview | HCI

While at the IPF Bangladesh industry fair, we certainly couldn't miss HCI Industry, which has been operating in the Bangladesh market for many years. This time, Jacky from HCI has shared his point of view on Bangladesh's industry and how Taiwan does business in Bangladesh. We have talked about the differences between the markets in other Asian regions. Let's take a look at HCI Jacky's interview.

Co-rotating Twin Screw Extrusion | CYKF

Did you know that? Because of the low cost and material versatility, strand pelletizing is the most commonly used pelletizing system. Description: 1. Heating & Cooling System: The material can keep the best temperature in the manufacturing by alternatively using hot water and cold water. 2. Stable Feeding System: The designed screw can avoid material stuck and causing uneven feeding. The feeding quantity can be adusted according to needs. 3. Side Feeder: Used for adding additives including powder, liquid, or pellet type, the side feeder can arrange an automatic system that supplements additives by itself. 4. Vacuum Unit: Purify the pellet by getting rid of exhaust gas or steam from materials. 5. Water Cooling Unit: The water tank cooled the strand plastic, and the organized water tank remains the proper temperature to make the plastic straight and unbroken. 6. Dryer: The dryer removes water from the strand plastic surface with strong wind, and the removed water will return to the water tank eventually. 7. Pelletizer: The pelletizer cut strand plastic into pellets, and the rotate speed can adjust freely, customers can also change other models for bigger productivity. More product information please visit our website: https://www.cykf.com.tw/tw/product/Strand-Pelletizing-System.html

WEI MENG | WMD Onion Bag Making Machine

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets. This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system. If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business. Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making. This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.