How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry. What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected? Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide. Topics Covered: U.S. reciprocal tariffs overview Strategic moves for manufacturers in 2025 Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

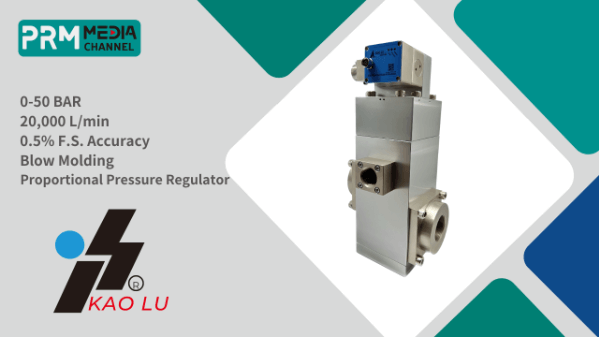

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

2023 IPF Taiwan Manufacturer Interview | HCI

While at the IPF Bangladesh industry fair, we certainly couldn't miss HCI Industry, which has been operating in the Bangladesh market for many years. This time, Jacky from HCI has shared his point of view on Bangladesh's industry and how Taiwan does business in Bangladesh. We have talked about the differences between the markets in other Asian regions. Let's take a look at HCI Jacky's interview.

Crystallized Hopper Dryer(CHD) | YANN BANG

Our PET / PLA Crystallizer is a closed-loop heating system continuously to re-crystallize PET amorphous resin and covert it into crystalline state. FEATURES The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time. YANN BANG Crystallized Hopper Dryer is the best choice for PET users. 1. SAVE COST. With YANN BANG's patented drying technology,the crystallized hopper dryer mixes the resin evenly while drying and shortens the drying time. 2. PREVENT BRIDGE MAKING. When drying oily,sticky,abnormal shaped resin,it is easy to have the bridge making.To use the crystallized hopper dryer can prevent the bridge making effectively. 3. NUMEROUS MIXERS AVAILABLE. Different kinds of unique mixers to suit for your special needs.

Five-Layer Extruder & Cutting Machine | BONMART

【Machine Features】 Plastic material has its own characters. In co-extrusion system. BONMART uses and combines several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE) Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc. 【Company Intro】 BONMART offers complete-line including technology transfer, cost analysis, layout, installation, test run, training and satisfactory after sale services. Using our Squeezable PE Tube equipment is the best choice of good investment, Welcome to contact us for more details any time.

Circular Loom Machine - 6 Shuttle Circular Looms | HAO YU

Introducing 6 Shuttle Circular Looms Machine from HAO YU. With HAO YU HY7-m6SCL six shuttles circular loom is designed with 6 shuttles to perform tubular weaving at high speed up to 180 RPM which is the highest technology in this woven bag equipment field in Asia. It reaches outputs up to 140 meters per hour. In case warp and weft breaks (finished), the machine stops automatically, An auto compensation system is also equipped to prevent the machine from empty weaving, it is an advanced circular loom specially designed to meet the stringent productivity requirements of today. The circular looms equipped with European inverter and high quality components. HAO YU is applying patent in Taiwan, China, India, and other countries. 【Machine Features】 Low spare part consumption & easy maintenance Energy saving nearly 50% over conventional models Large weft yarn insertion capacity up to 1080 PPM(max) Flat yarn applicable weaving denier from 500-1200(standard) Large weft yarn carriage capacity up to 115mm(max) Equipped with European inverter for main motor Lubrication-free for shuttle & cam 【Optional Accessories】 Gusseting device Both sides heat slitting device and additional fabric winder Center unfold device with heat slitting device and extra large unwinder for cement bag industry 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

Corona Treater | CHAANG HORNG-

.For non-conductive substrates .400~1600mm treat width available .One / Two side treatment .25mm segmented electrode finger .Φ 2.5” treatment roller

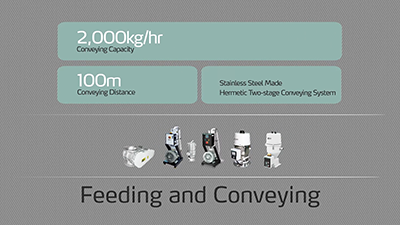

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

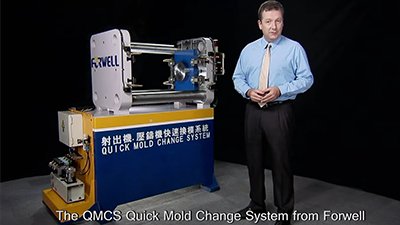

Quick Mold Change | FORWELL

Quick Mold Change - Quick Mold Change System-forwell-qmcs-en-Forwell Features • Decreased mold change time • Fully customizable to fit a wide range of machines • Safer operations • Reduced labor costs • Easy changeover for small batch runs System Introduction : Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

Two Platen Injection Molding Machine - 3500TPII | CLF-

➡️ Maximum injection weight 34 KG. ➡️ High stability, High efficiency, High energy saving.. ➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy. ➡️ Direct pressure clamping to make the mold evenly stressed. ➡️ Smooth, stable and powerful. ➡️ Uniform tension force on tie bars for dramatic increase of service life. ➡️ Simplified construction with no wearing problem on toggle clamp. Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry As PRM Media Channel, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! The Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the company’s profile and the current situation of COVID-19 in Mexico, the challenges they are having due to the pandemic, and their solutions to overcome those challenges.