Plastics & Rubber Machinery Videos

With PRM professional matching services, we labeled 15 Machinery Categories and more than 600 videos, for you to conveniently find a supplier that best suits your business.

ALL STYLES

AUXILIARY EQUIPMENT AND INTEGRATED AUTOMATION

BLOW MOLDING MACHINES

EXTRUDERS AND EXTRUSION LINES

FINISHED/SEMI-FINISHED PRODUCTS

INJECTION MOLDING MACHINES

MOLDS AND DIES

PACKAGING MACHINERY

PARTS AND COMPONENTS

PLASTIC CONVERTING MACHINES

PLASTIC RECYCLING & MATERIAL PROCESSING MACHINERY

PRINTING MACHINERY

RAW MATERIALS & ADDITIVES

RUBBER PROCESSING MACHINERY

SHOE MAKING MACHINERY

THERMOFORMING MACHINES

High Speed Co-Extrusion Coating and Laminating Machine WCL-H-1300 (300 m/min)

WORLDLY In this fast-changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds of resin or more by two or more extrusion units to create multi-function extrusion layers.

The variety of resin after melted and go through the feed block then join into the T-die. The side screw has corrosion resistance treatment. It’s fine to work with acid copolymer resin, such as EVA, EAA, EMAA, and Surlyn, etc. The barrel heated by a ceramic heater to ensure more energy-saving and short start up time.

Worldly also developed the exclusive extrusion output control system with Germany leading dosing system company. So it provides the very accurate and stable output and coating gauge control during the production. It can save more material especially for the long run jobs.

The high-speed H series version of the rewinding splicer adopted with a tracking roller device. It provides two kinds of gap & contact winding mode and gives a uniform and perfectly straight finished winding during high speed running. Also the taper tension can properly control the winding from the beginning roll. So it can reduce the wastage and avoid the wrinkle generate at the inner roll.

Worldly utilizes only high quality imported T-dies and maintains a ±3% thickness variation. The inner deckle system is customized in-house to reduce trim and provides uniform high-speed production.

Solventless Lamination - Solventlless Laminator-LM-SF1300-Webcontrol Webcontrol

Machinery Corp has been specializing in manufacture of Solventless Lamination since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Lamination with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Lamination service ensure our worldwide customers must be satisfied.

ROTOFLEXO Stack Type Flexo Printing Machine

- 250 M MIN

- Double Side 2+2

- High precision cylinders, anilox rollers, and guiding rollers

- Automatic temperature control system

- High precision gear transmission system

- Closed chamber doctor blade system

- Automatic tension, edge, and web guide control

- High speed forward and reverse printing desk motion

- High precision ball screw designs for key components

- Motorised horizontal and longitudinal registration system

- Electric heat/drying system

- CNC desk position control

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000, MING JILEE

Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

MACHINERY IN THE VIDEO: CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO

- 8 colors central impression flexo printing machine

- High precision stainless-steel impression drum imported from Italy

- Automatic water temperature control system

- High precision gear transmission system

- Closed chamber doctor blade system

- Automatic tension, edge, and web guide control

- High speed forward and reverse printing desk motion

- High precision ball screw designs for key components

- Motorised horizontal and longitudinal registration system

- Electric heat/drying system

- CNC desk position control

6 Colors High Speed Stack Flexo Printing Machine PKF-1000-6 | PRINTPLAS

The Central Impression drum surface is precisely grinded and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transported and precisely printed.

Machine framed with 80MM cast metal plate, provide a very steady, vibration free foundation for the printing work.

High sensitive feed in and feed out tension controlling system, incorporated with synchronized motion control to ensure constant tension during printing.

Super fine printing adjustment device to secure printing accuracy at each printing station.

Long arch drying tunnel with strong blower to ensure drying of ink during high speed operation.

Machine controlled by Japan PLC system with full color user friendly HMI. Full servo system with PLC memory module auto printing controlling system can be added to achieve a high level automation. Quick change over sleeve system can be adopted as optional.

Solventless Laminating-Solventlless Laminator-LMC-SF1300| WEBCONTROL

Webcontrol Machinery Corp has been specializing in manufacture of Solventless Laminating since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Laminating with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Laminating service ensure our worldwide customers must be satisfied.

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY

Machine Specifications

- Max machine speed: 350 m/min

- Web width: 1000 / 1200 / 1300 mm

- Printing cylinder circumference: 350 - 900 mm

- Material diameter: 800 / 1000 mm

- No. Color: 10 colors

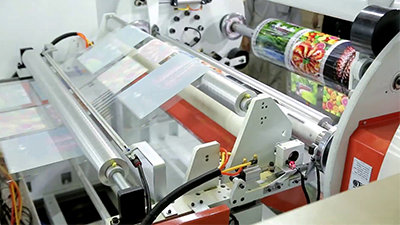

Thermoforming Machine-Continuous Thermoforming Machine

Chuliing Machinery Co., Ltd was established in 1985 and is now an expert in manufacturing Thermoforming Machine. Our products are sold worldwide and we are well-known die cutting machine manufacturer. Chuliing Machinery has a commitment to technological innovation so as to benefit his customers and agents from all aspects. We also dedicate ourselves to develop automatic equipment and to train our employees to further enhance our Thermoforming Machine product quality.

We are pleased to interview Willie Huang from SUNKIST, a company from Taiwan with a great reputation for producing the machinery required for flexible and rigid polyurethane foam. This time Mr. Huang gives us a brief introduction of the company and how they are developing new machines that fulfill the new trends in the market, also making emphasis on their social responsibility with the environment. He mentions how Sunkist is facing the current challenges, such as Global warming, giving examples of how the industry is working in plastic reduction. Also, we get their new machinery introduction during K 2019, for more details please click the info card on the video or visit our B2B Platform.

Calcium Carbonate Compounding Pelletizing Plant-Genius

Specializes in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant, GENIUS MACHINERY CO., LTD. was established in 1992, professional in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world.

Product Feature Applicable materials For PP、LDPE、PS. For adding in plastic product production; maximum caco3 up to 80%~90%.

• Save cost, reduce expenditure, strengthen competition.

• Pellet is round and flat in shape, smooth feeling, well plastified, good dispersibility.

• Easy operation

We are a pioneer of twin screw extruder.

Description: TWIN SCREW EXTRUDER

⚫With two parallel counter-rotating screws for the palletizing.

⚫Reduction and torque-distribution unit with hardened, ground shafts and gear.

⚫Long service life for the processing units due to lower specific drive energy.

⚫Increased process reliability due to modern control technology.

⚫Easy maintenance and service. DIE FACE CUTTING

⚫Hinge flange type.

⚫High speed rotation of the knives.

⚫Continuous production of granulate. VIBRATION COOLER

⚫Up & Down two vibrating bed. SILO TANK

⚫Stainless steel. Our Service: Technology innovation, perfect service, and internationalization are always our core values, with this mission we have become the pioneer of twin screw extrusion in the global market and a reliable partner of our customers.

TwinScrew will never stop progressing in the field of PVC extrusion and twin screw extrusion; we will no doubt lead the twin screw technology into an ultimate and great attainment.