Issue 64

Souscrire

Blown Film Machine for Flexible Packaging

Polystar

designs and manufactures a wide range of blown film extrusion machine with

flexibility depending on customer's special needs and requirement.

Since the usage of recycled material and CaCO3 compound is prevalent in many markets today, Polystar has re-designed its screws specifically to work with these type of material in the mixture. The bi-metallic treatment prevents the screw from wearing out fast when running abrasive material.

The extrusion line with longer screw L/D produces film of higher resistance in addition to having a good mixing and film quality. All Polystar machines are equipped with Siemens energy saving motors for a lower energy consumption during operation.

In addition to having experience with blown film extrusion machines, another advantage of Polystar is that it also produces film recycling machines. In most cases, customers are supplied with a package consisting of both, film extrusion and recycling lines.

This opportunity gives Polystar the leverage to work even closer with its customers and to understand better their needs. From constant customer feedback and information on new market trends, Polystar is able to modify and re-engineer its machines to be more efficient, user-friendly and durable to stay competitive in the market. For film producers, Polystar has often offered a combination of A-B-A blown film lines and recycling machines, giving the customer the advantage of producing economic 3 layer film with 60% calcium carbonate in the middle layer, mainly for the production of T-shirt and garbage bags.

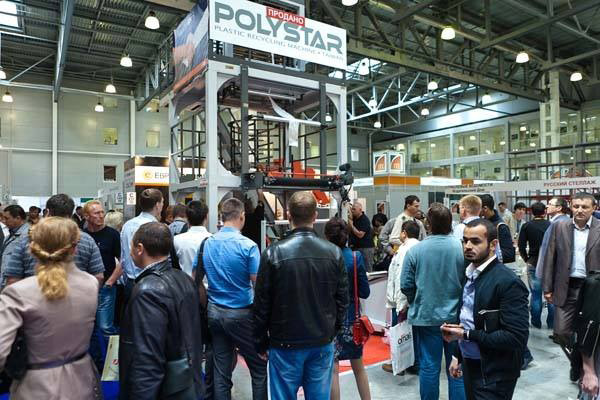

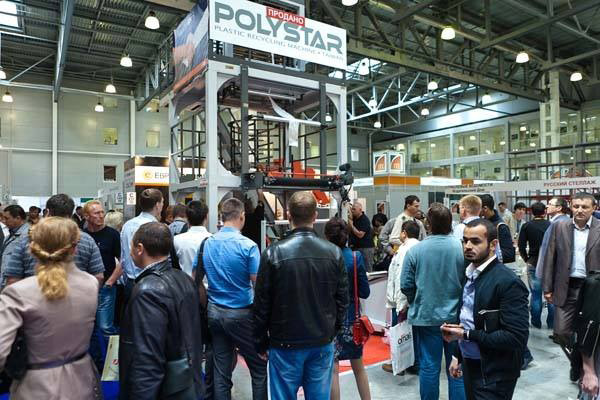

Polystar has already exported more than 2,700 sets of machines to more than 100 countries in the past 25 years. Polystar also participate major international shows. This September, Polystar will introduce its new type three layer blown film machine at Taipei Plas. Immediately after Taipei Plas this September, Polystar will host an open house event in its testing center in Tainan city, Taiwan from October 1st to October 3rd. Customers are very welcomed to sign up for the event and see both Polystar's latest film recycling blown film extrusion machines in operation. A variety of film extrusion and recycling equipment will be demonstrated during the open-house event.

Since the usage of recycled material and CaCO3 compound is prevalent in many markets today, Polystar has re-designed its screws specifically to work with these type of material in the mixture. The bi-metallic treatment prevents the screw from wearing out fast when running abrasive material.

The extrusion line with longer screw L/D produces film of higher resistance in addition to having a good mixing and film quality. All Polystar machines are equipped with Siemens energy saving motors for a lower energy consumption during operation.

In addition to having experience with blown film extrusion machines, another advantage of Polystar is that it also produces film recycling machines. In most cases, customers are supplied with a package consisting of both, film extrusion and recycling lines.

This opportunity gives Polystar the leverage to work even closer with its customers and to understand better their needs. From constant customer feedback and information on new market trends, Polystar is able to modify and re-engineer its machines to be more efficient, user-friendly and durable to stay competitive in the market. For film producers, Polystar has often offered a combination of A-B-A blown film lines and recycling machines, giving the customer the advantage of producing economic 3 layer film with 60% calcium carbonate in the middle layer, mainly for the production of T-shirt and garbage bags.

In Taipei Plas and NPE (Orlando), Polystar will be having live demonstration of its multi-layer blown film lines.

It will also be showing its film recycling line in Plastimagen this November at stand 1436.

Polystar has already exported more than 2,700 sets of machines to more than 100 countries in the past 25 years. Polystar also participate major international shows. This September, Polystar will introduce its new type three layer blown film machine at Taipei Plas. Immediately after Taipei Plas this September, Polystar will host an open house event in its testing center in Tainan city, Taiwan from October 1st to October 3rd. Customers are very welcomed to sign up for the event and see both Polystar's latest film recycling blown film extrusion machines in operation. A variety of film extrusion and recycling equipment will be demonstrated during the open-house event.

For

more information please contact us at [email protected] or speak to one of Polystar's local agents in your region.

Visit POLYSTAR at Taipei Plas 2014

DATE:2014/09/26-30

VENUE:TWTC NANGANG Exhibition Hall, 1F

Booth No. K108

More Information on PRM: http://www.prm-taiwan.com/com/polystar.html

Visit POLYSTAR at Taipei Plas 2014

DATE:2014/09/26-30

VENUE:TWTC NANGANG Exhibition Hall, 1F

Booth No. K108

Official Website: http://www.polystarco.com

E-News Categories

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets