Successful in Plastivision India2013 – Exclusive interview with HSINPOW

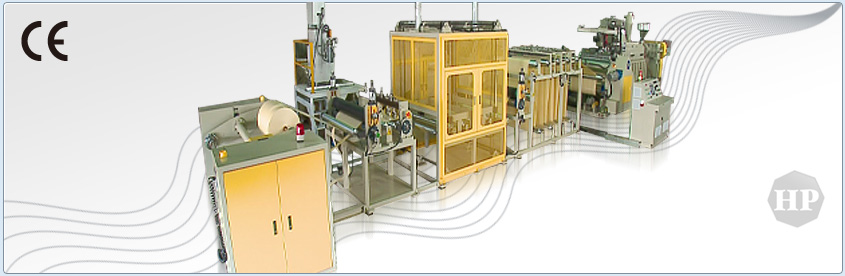

In this Plastivision India 2013, we have seen the great exhibition which is hold by HSINPOW, the leading plastic extrusion machine manufacturer in Taiwan. With many year experiences, HSINPOW has the ability of providing the best solution for each customer, and we are glad to see HSINPOW’s achievement today. Furthermore, it is our honor to have an exclusive interview with Mr. Wang of HSINPOW, and see him introducing the best seller machine of HSINPOW- the PP /PE /PS /ABS /PLA Sheet Single-Screw Extruder to our readers.

In this Plastivision India 2013, we have seen the great exhibition which is hold by HSINPOW, the leading plastic extrusion machine manufacturer in Taiwan. With many year experiences, HSINPOW has the ability of providing the best solution for each customer, and we are glad to see HSINPOW’s achievement today. Furthermore, it is our honor to have an exclusive interview with Mr. Wang of HSINPOW, and see him introducing the best seller machine of HSINPOW- the PP /PE /PS /ABS /PLA Sheet Single-Screw Extruder to our readers.Interviewee: Mr. Wang of HSINPOW

Q1. What is the motivation for you to attend Plastivision 2013?

We already have many customers in India since we started the sheet business in 2003. Therefore, the purpose to attend this exhibition is not only to develop new clients, but also to serve the current clients.

Q2. Could you introduce to our readers about the main equipment of this exhibition?

This time, our main product is Sheet making machine. This is equipment can crush the recycle material and process it into new sheet, and manufactures PP food containers which is heat-resistant and microwavable. The demand of PP food container is growing in India, therefore, there are many clients have a huge interest in this equipment. We have sold this kind of machine more than 20 lines in India.

Q3. What is your advantage for Indian clients?

HSINPOW product price is reasonable and the production quality is very stable. We ask customers’ opinions every 6 months, in order to maintain the clients. And also, HSINPOW’s customized machines meet the multiple demand of India market and can be adjusted for satisfying different clients.

Q4. Do you consider finding a local agent or establishing a branch in India?

Except of Russia area where we already have a local agent in, we are still looking for agent in India, Indonesia, Vietnam, and South Africa and so on. We expect to create a network in Southeast Asia for providing an in-time communication service.

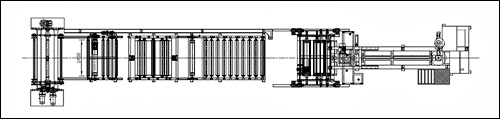

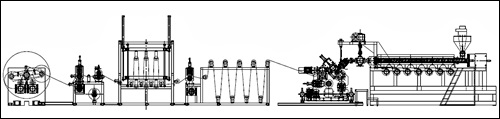

PP /PE /PS /ABS /PLA Sheet Single-Screw Extruder

|

|

Machine Introduction

The PP /PE /PS /ABS /PLA Sheet Single-Screw Extruder has the independent temperature controller for each 5 form rollers in the machine. And the temperature deviation can be control in 1℃. This gives the flexibility in the production. Moreover, there is a buffer attached in the middle of production process which can extend the time for changing the shaft. The operator can have sufficient time for shaft changing without worrying materials coming too quickly. Most importantly, this extruder has the T-die with 45° angle. With this design, the materials can be loaded evenly and reducing the bank line problem. This sheet single-screw extruder has excellent functions which guarantee to produce the quality sheet in each production.

Machine Features

1. Improving the complicated shaft changing process, it can save labor cost and time.

2. Easy to change material color without any residue.

3. Adjustable speed to co-operate with the production rate.

4. More safety than traditional roller type machine.

5. High extruding amount and low power consumption.

About the Manufacturer

HSINPOW machinery is a leading plastic extruder sheet making machine manufacturer in Taiwan. For years, they have devoted in research, development and design for various kinds of quality plastic extruder machines. There are over 300 sets of our production lines operated with high quality and product capacity. HSINPOW has received high reputation among the world. Their machines have been well promoted in markets such as China, Russia, Japan, Vietnam, Malaysia, Indonesia, India, Thailand, Saudi Arabia, Brazil, Tunisia etc. With innovative R& D, on-going testing and our know-how, they are confident to provide the best quality plastic extrusion machine and after-sale service for your best production and profit. We believe our customer's growth is our success!

More information on PRM: www.prm-taiwan.com/com/hsinpow.html

Official Website: www.hsinpow.com

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets