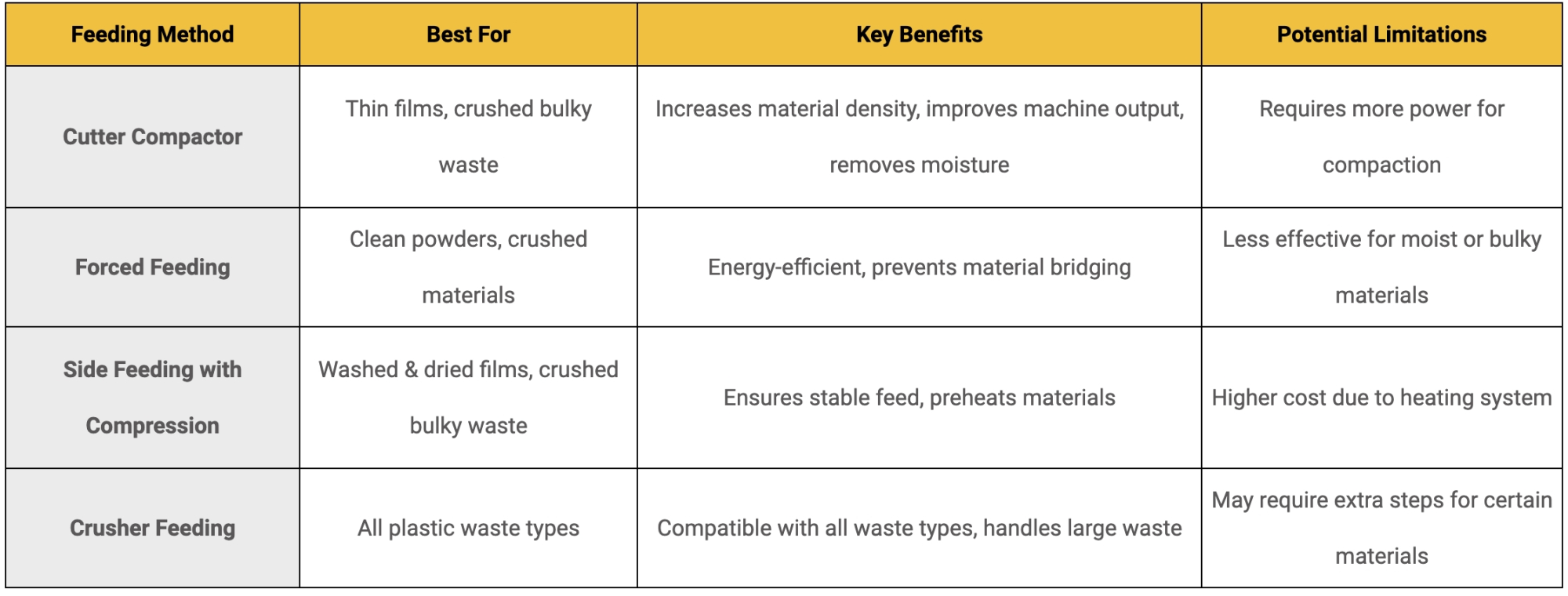

Comparing Feeding Methods for Plastic Recycling Equipment: Which One Suits Your Needs?

In the realm of plastic recycling, the way materials are fed into recycling equipment plays a pivotal role in determining overall efficiency and output. Whether handling thin films, bulky plastic waste, or powders, selecting the appropriate feeding method is essential for optimizing machine performance and maintaining consistent production. This article delves into the primary feeding methods used in plastic recycling equipment, highlighting their unique features and ideal applications.

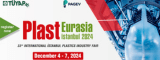

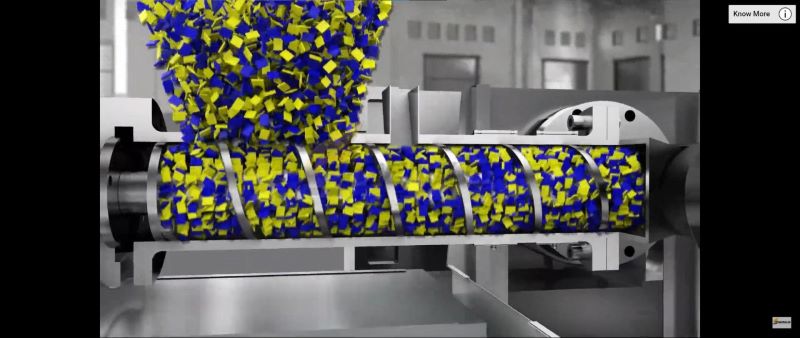

1. Cutter Compactor

The cutter compactor, also known as the agglomerator, is specifically designed to manage thin films and crushed bulky waste. By leveraging friction to generate heat, this method compresses lightweight, voluminous materials into denser, manageable blocks.

Key Advantages:

-

Compression and Feeding: Lightweight materials are transformed into dense blocks, boosting the overall output of recycling machines.

-

Moisture Removal: The compaction process preheats the materials, enabling moisture to evaporate and reducing the degassing workload on the extruder.

Best For: Thin films and crushed bulky waste. This method significantly enhances material preparation and overall recycling efficiency.

2. Forced Feeding

Ideal for clean, dry materials such as powders and crushed waste, forced feeding offers a cost-effective and energy-efficient solution. Unlike other methods, it eliminates the need for preheating during the feeding stage.

Key Advantages:

-

Economic Choice: Minimizes energy consumption by bypassing the preheating process, making it an excellent option for facilities focused on reducing operational costs.

-

Anti-Bridging Screw: Utilizes a specially treated screw to prevent material bridging, ensuring a steady, consistent feed into the extruder.

Best For: Powders and crushed waste where bridging could disrupt the recycling process.

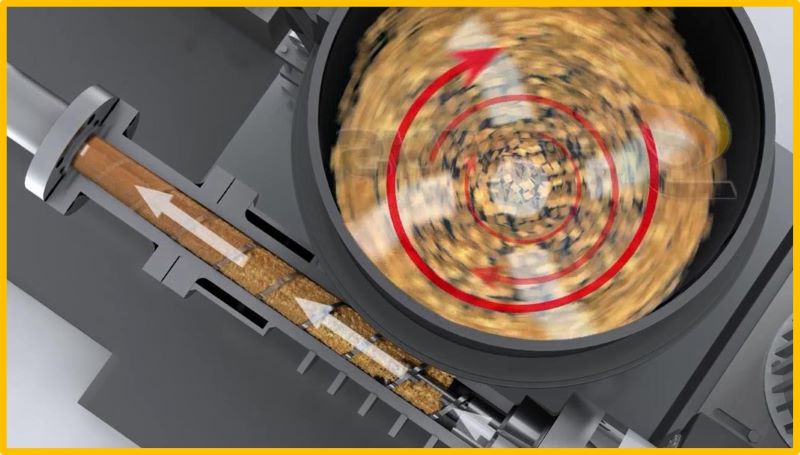

3. Side Feeding with Forced Compression

This advanced method is designed to maximize feeding volume and improve material flow, making it particularly suitable for washed and squeezed films, as well as crushed bulky waste.

Key Advantages:

-

Increased Feeding Volume: Ensures a stable feed into the extruder, keeping the screw fully loaded to maximize machine output.

-

Material Preheating: Features an integrated heating system to preheat materials during feeding, reducing the extrusion process workload.

Best For: Operations requiring stable feeding and high production efficiency, especially for films and bulkier waste materials.

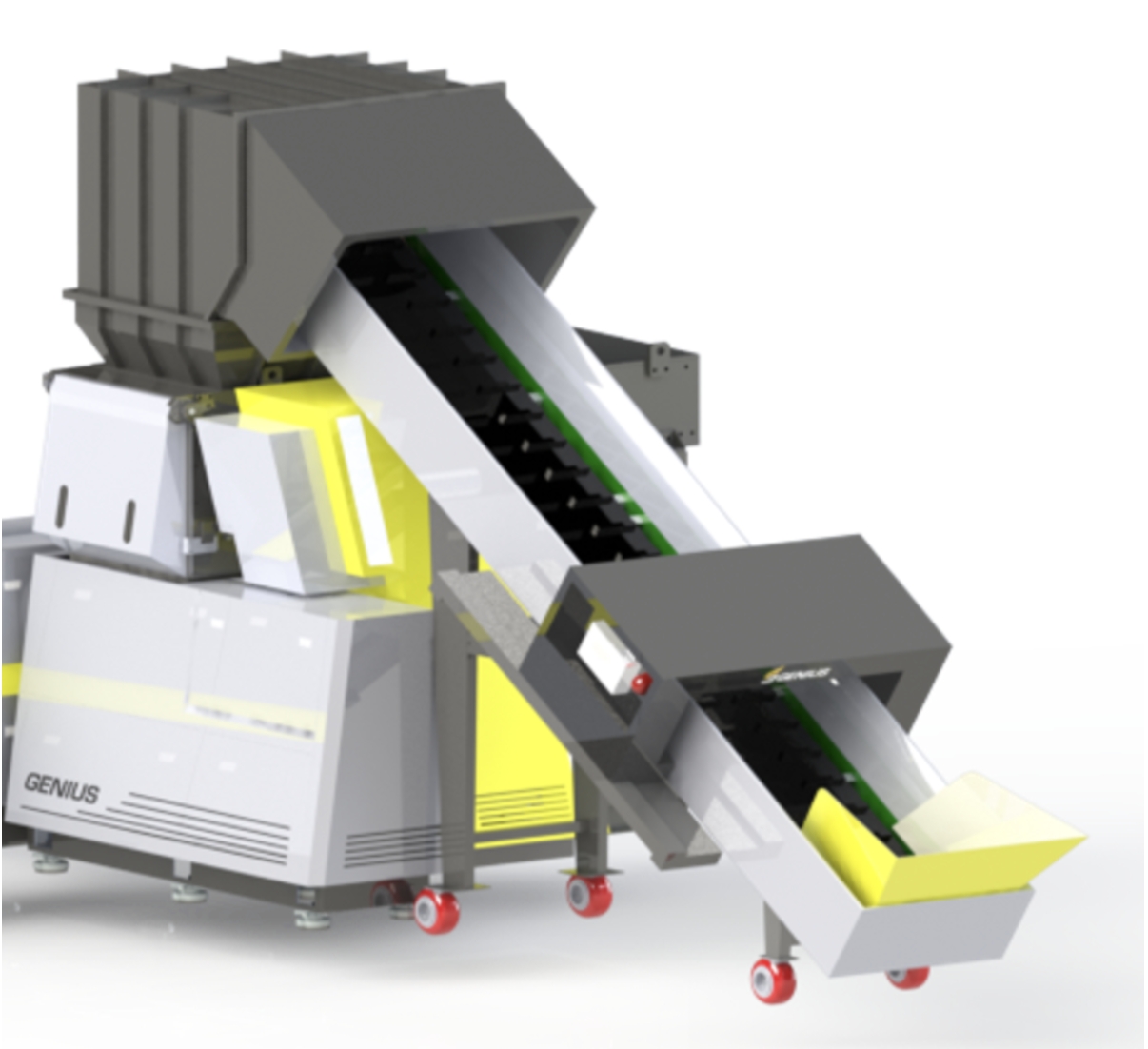

4. Shredder Feeding

For facilities managing diverse plastic waste types, shredder feeding is a versatile and effective solution. It breaks down large plastic waste pieces that are too big to feed directly into the recycling process.

Key Advantages:

-

All-Inclusive Solution: Highly compatible with all plastic waste types, shredding oversized materials into manageable sizes.

-

Streamlined Processing: Efficiently crushes and feeds large waste directly into the extruder, simplifying the recycling workflow.

Best For: Recycling operations handling a wide range of materials, offering flexibility and high compatibility across various waste types.

Maximizing Recycling Efficiency: Next Steps

Choosing the right feeding method is a critical step toward optimizing your recycling operations. Whether you opt for cutter compactors, forced feeding, side feeding with compression, or shredder feeding, the right choice can dramatically enhance your equipment's efficiency and output.

To further improve your recycling process, consider additional equipment such as Screw Press Dewatering Machines, which are indispensable for moisture removal and material preparation. Click here to learn more about Genius Screw Press Dewatering Machines.

For tailored advice on the best feeding methods and recycling equipment, contact us today. We’re ready to help you achieve peak performance for your recycling operations.

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets