From General to Customized Blown Film Machinery: How Kang Chyau Evolved into a Professional Blown Film Consultant

Taiwan's Plastics and Rubber machinery industry has long been renowned for its high quality and customization capabilities. PRM's Spotlight initiative this year aims to highlight the unique strengths of Taiwanese machinery suppliers on a global scale, particularly their ability to offer customized solutions during the innovation and R&D process, allowing international clients to better understand and recognize Taiwanese manufacturers.

Kang Chyau, based in Taiwan, specializes in the development and manufacturing of plastic blown film machines. Established in 1988 by Mr. Kang, the company has garnered global clients with its expertise and technology, demonstrating flexibility in meeting diverse clients’ demands.

In its early days, Kang Chyau pioneered a novel approach by using a 3.5-ton truck to transport its new blown film machine, conducting nationwide demonstrations. This "on-site testing and direct sales" allowed domestic buyers not only to see the machines but also to quickly understand their operation and advantages. This approach rapidly earned Kang Chyau recognition in the domestic market. Once the local market was stable, Kang Chyau actively participated in international exhibitions, significantly enhancing its global visibility and gaining international recognition. This opened the door for Kang Chyau to enter global markets.

Kang Chyau Industry: Standing Firm in the Blown Film Industry as the Exclusive Consultant for Clients

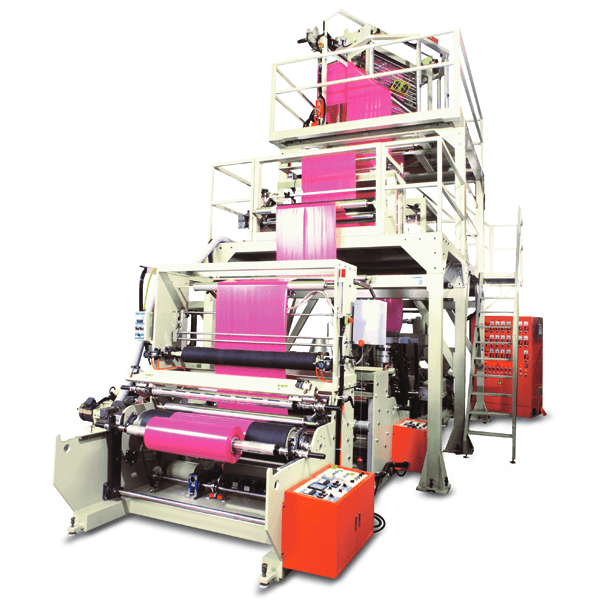

Kang Chyau offers both general type and customized type blown film machines, with customization being a major advantage. In addition to designing machines based on customer needs, Kang Chyau combines years of experience to offer professional advice, providing customers with a guide to help them choose the right blown film machinery.

For customers just starting a blown film factory or entering the blown film industry, Kang Chyau usually recommends beginning with general type machines. Once customers have built a certain client base and acquired technical expertise, Kang Chyau then suggests upgrading to customized machines. Kang Chyau requires customers to provide information on the film materials and applications to offer more precise machine recommendations.

For single-layer blown film machines, Kang Chyau adjusts the machine based on the materials used, ensuring stable, high-quality production for large-scale output. If the customer needs to produce multi-layer films, they customize the machine according to specific requirements. Kang Chyau is also proficient in recommending materials suitable for blown film machines, considering the wide range of available materials in the market. From common materials like PE, HDPE, LDPE, and PP to biodegradable materials such as PBAT, PLA, PS, and PVA, Kang Chyau advises customers on material choices based on different production needs.

With years of experience and technical expertise, Kang Chyau has proven itself capable of meeting diverse customer needs, transitioning from merely fulfilling customer demands to becoming their exclusive professional consultant.

Two Layer HDPE/LDPE/ LLDPE High Speed Plastic Inflation Machine KMTL-55

Three Layer Blown Film Plastic Inflation Machine KMTL-E3

Kang Chyau helps Gold Coast Client Expanded with Customized Blown Film Machines to Increase Capacity and Optimize Space Utilization

Recently, a customer from Gold Coast in Africa ordered six connected blown film machines from Kang Chyau. Having worked with Kang Chyau for over ten years, this customer has developed great trust in the company's quality and after-sales service. When they planned to expand their factory, they once again chose Kang Chyau as their supplier, ordering six connected single-layer blown film machines, each with a roll width of 500mm, classified as small-sized blown film machines.

The client's primary need was to optimize space utilization to save factory space. Additionally, due to the high-quality requirements for finished products, the client specifically ordered a rotary die to ensure bag flatness. Based on these specific needs, Kang Chyau custom-built machines, significantly boosting the client's production capacity.

Continuous Improvement, Creating Success

At the end of the interview, Gina from Kang Chyau Industry confidently stated, "Kang Chyau will continue to adhere to the belief of ‘meeting demands and improving processes,’ providing customers with diverse and multifunctional machine models. Moving forward, with over 60 years of industry experience, Kang Chyau will continue to offer high-quality blown film solutions to the global market."

In the future, Kang Chyau Industry will keep innovating and advancing, establishing itself as the most trusted consultant for clients in the blown film field.

KANG CHYAU INDUSTRY CO., LTD. provides expert plastic bag technology services to the world’s soft packaging market. Since its founding in 1988, the company has upheld its research and development concept of “staying close to the needs and demands while improving manufacture process” to continue the improvement and production of high quality blown film machines as well as whole plant plastic bag machinery and equipment, which ultimately allows KANG CHYAU to meet the customized demands of clients in terms of being energy-saving, high output, low noise output, maintain work safety and other aspects.

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets