TungYu Servo Press: Revolutionizing Manufacturing with Sustainable Power

Are you looking to enhance your manufacturing processes while minimizing environmental impact? TungYu's advanced all-electric servo press offers a sustainable and efficient solution. By replacing traditional hydraulic systems with high-performance servo motors, our servo press achieves significant energy savings and a reduced carbon footprint.

Why Choose TungYu Servo Press?

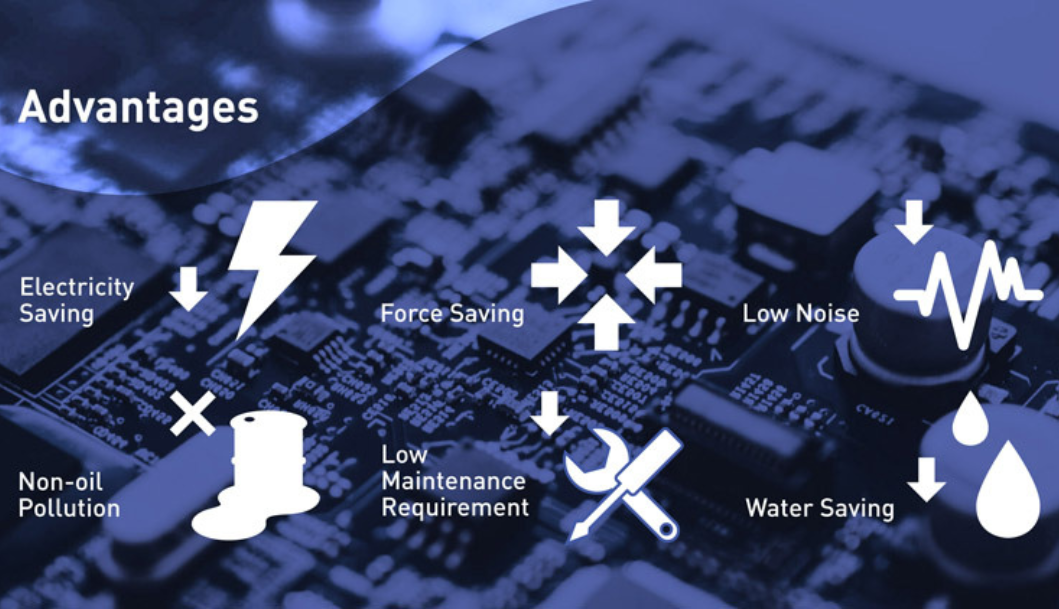

TungYu's servo press provides numerous advantages:

- Unmatched Energy Efficiency: Experience up to an 80% reduction in energy consumption compared to traditional hydraulic presses. This substantial decrease not only lowers operational costs but also significantly reduces your carbon footprint, making it an ideal choice for businesses seeking to improve their ESG performance.

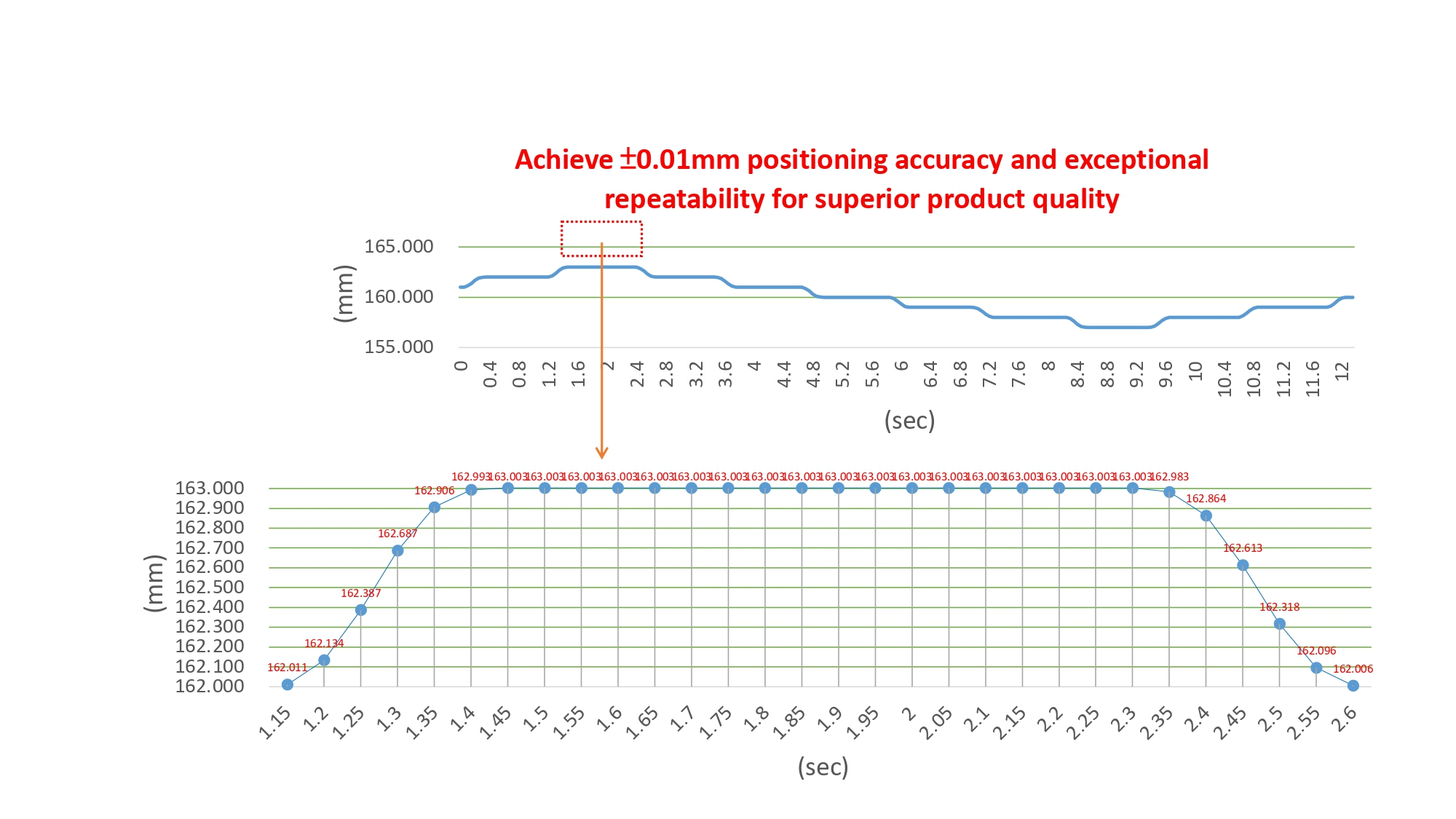

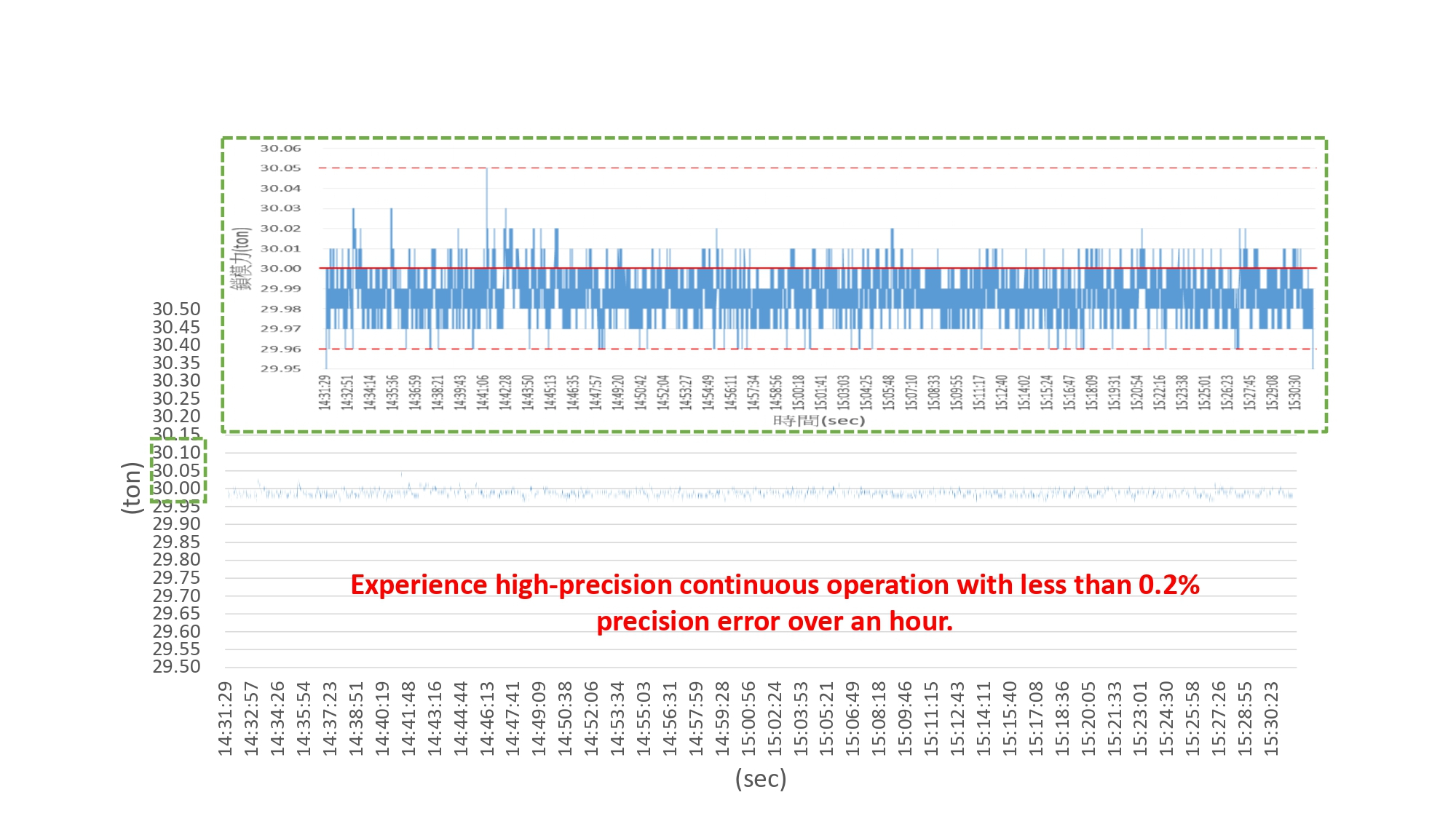

- Precision and Accuracy: Achieve ±0.01mm positioning accuracy and exceptional repeatability for superior product quality. This level of precision is essential for applications demanding tight tolerances.

- Compact Design: Our space-saving design maximizes floor space utilization, making it ideal for diverse production environments.

- Quiet Operation: Reduced noise levels contribute to a more comfortable and productive workspace, improving your workplace environment.

- Lower Maintenance Costs: With fewer moving parts and reduced wear and tear, our servo press leads to lower maintenance expenses over the long term.

- Carbon Emission Monitoring: Built-in carbon emission monitoring system promotes sustainable manufacturing practices and helps you meet your sustainability goals.

How Does It Work?

TungYu's servo press utilizes advanced servo motor technology to drive the press action. Unlike traditional hydraulic systems, servo motors offer precise control over force, speed, and position, improving productivity and product quality. Additionally, eliminating hydraulic fluids reduces the risk of leaks and contamination, making the servo press a safer and more environmentally friendly option.

The Benefits of Servo Technology

- Enhanced Energy Efficiency: Servo motors only consume energy when work is being done, leading to significant energy savings and a lower total cost of ownership.

- Precise Control: Servo motors offer precise force control, speed, and position, resulting in improved product quality and reduced scrap rates.

- Reduced Maintenance: With fewer moving parts and less wear and tear, maintenance costs are significantly reduced.

- Quiet Operation: Servo motors operate quietly, reducing noise pollution in the workplace and improving worker satisfaction.

- Environmental Friendliness: Removing hydraulic fluids reduces the risk of leaks and contamination, protecting the environment and ensuring compliance with environmental regulations.

Embrace Sustainability with TungYu

You contribute to sustainability by choosing TungYu. Our commitment to innovation and environmental responsibility is reflected in every product we create. Join us in driving the future of manufacturing.

Experience TungYu's Servo Press at SEMICON 2024, Rubber Tech 2024 and TaipeiPlas

Want to see our servo press in action? We invite you to SEMICON 2024m, RubberTech 2024 and TaipeiPlas to see our latest products. Our experts will be on hand to answer any questions you may have.

|

|

|

|

|

|

|

|

|

Ready to Experience the Future of Manufacturing?

Contact TungYu today to learn more about our advanced servo press and how it can benefit your business.

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets