Full Shine Machinery's Expertise in PC Water Bottles Making Machine

HEADLINE

Full Shine Machinery's Expertise in PC Water Bottles Making Machine

Full Shine Machinery has 30 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.

HOT NEWS

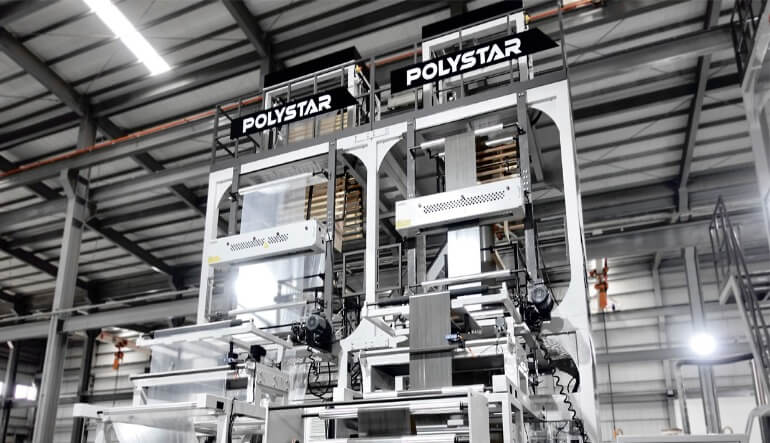

Flexible POLYSTAR Blown Film Extruders for Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. Let's take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging.

For the First Time in 3 Halls: The 9th Agrofood & Plastprintpack Nigeria to Become the Largest yet

Building on the momentum of the highly successful March 2023 edition, the organizers are proud to announce the elevated standards set for the upcoming 9th edition. With an unwavering commitment to excellence, every aspect of the event has been meticulously enhanced to deliver an unparalleled experience, surpassing previous benchmarks.

Advanced Technologies Could Process 20 Percent of U.K.’s Waste Tires

Norwegian rubber waste recycler Wastefront is set to open a $120 million plant in Sunderland, England, either late in 2024 or early 2025. The plant will utilize pyrolysis to convert end-of-life tires into tire-derived oil (TDO), which will then be refined into various combustion fuels, including diesel. Wastefront claims that the TDO produced will be cleaner than fossil diesel and cost-competitive, depending on the grade. It is expected to be cheaper than hydrotreated vegetable oil and similar biofuels.