40th Techmation: Digital Low Carbon Dual Wheel Drive, Intelligent Manufacturing in the Future

2024 marks the 40th anniversary of Techmation. Over the past 40 years, Techmation has taken the first Chinese screen injection molding machine controller in Asia as the starting point, vertically breaking through technological barriers, horizontally expanding product applications, and steadily drawing an industrial application map with Techmation control system as the core. Faced with the constantly growing demand for intelligent manufacturing and low-carbon green production, Techmation has completed strategic planning and layout, achieved product upgrades and iterations, and will present advanced product solutions and industrial transformation at Shanghai CHINAPLAS in 2024.

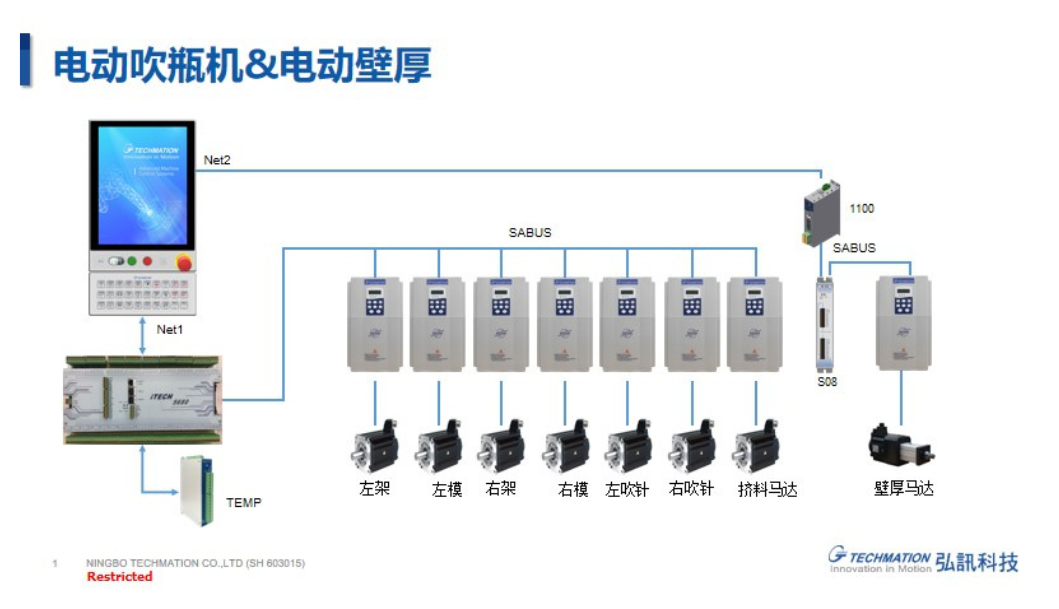

Low carbon application: Control system of fully electric hollow blow molding machine

The hollow blow molding industry is facing significant challenges in 2023, such as weak external demand for exports, weakened domestic demand, and increased operational pressure on enterprises; Product homogenization is severe, and industry competition has entered a white hot stage. Fortunately, challenges often coexist with opportunities, and we can also see that the resilience of emerging and differentiated products is often stronger than that of standard products.

Therefore, in the trend of digital evolution, Techmation actively researches and applies the achievements of the green economy, and launches an all-electric solution for hollow blow molding machines. It can efficiently meet personalized production needs through customized software program development. At the same time, considering the high requirements for wall thickness in hollow blow molded products, Techmation has added a wall thickness control function in the solution, which can ensure the uniformity of product wall thickness and achieve precise control of wall thickness, effectively improving the quality of blow molded products and enhancing the product competitiveness of customer enterprises.

Compared to ordinary hydraulic bottle blowing machines, the Techmation fully automatic bottle blowing machine has achieved optimization in control accuracy, energy consumption, and output. This scheme uses a roller screw drive electric cylinder instead of traditional oil pressure, making the mechanical structure more compact and compact, reducing the volume and footprint of the machine, and reducing energy consumption through an energy management system, achieving oil-free and pollution-free production processes. It is more suitable for the production of products with high environmental requirements, such as edible and medical products. In addition, the bottle blowing machine using the Techmation control system has a greater locking force. After using a planetary gearbox, it can generate a greater torque force, reduce the damage to the mold cutting edge caused by mold closing impact, and make the seam line of the blow molded product's cutting edge smoother and smoother. The overall operation of the machine is also more stable, with less impact and vibration caused by speed conversion during operation, and higher efficiency. It can achieve higher output during the production cycle.

In addition to the fully electric bottle blowing control system, at this year's CHINAPLAS exhibition, Techmation will also showcase new generation extruders, rubber machine solutions, HMI panels, J-generation electronic control, physical robotic arms, Techmation Cloud (rubber and plastic industry information management platform), etc. Welcome all new and old friends to Techmation booth (Hall 1.1 D46) for technical exchanges, celebrate the 40th anniversary with Techmation, and talk about the future of the industry together!

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets