CLF Advanced Production Efficiency: Cycle Time Reduction in Two Platen Injection Molding Machine

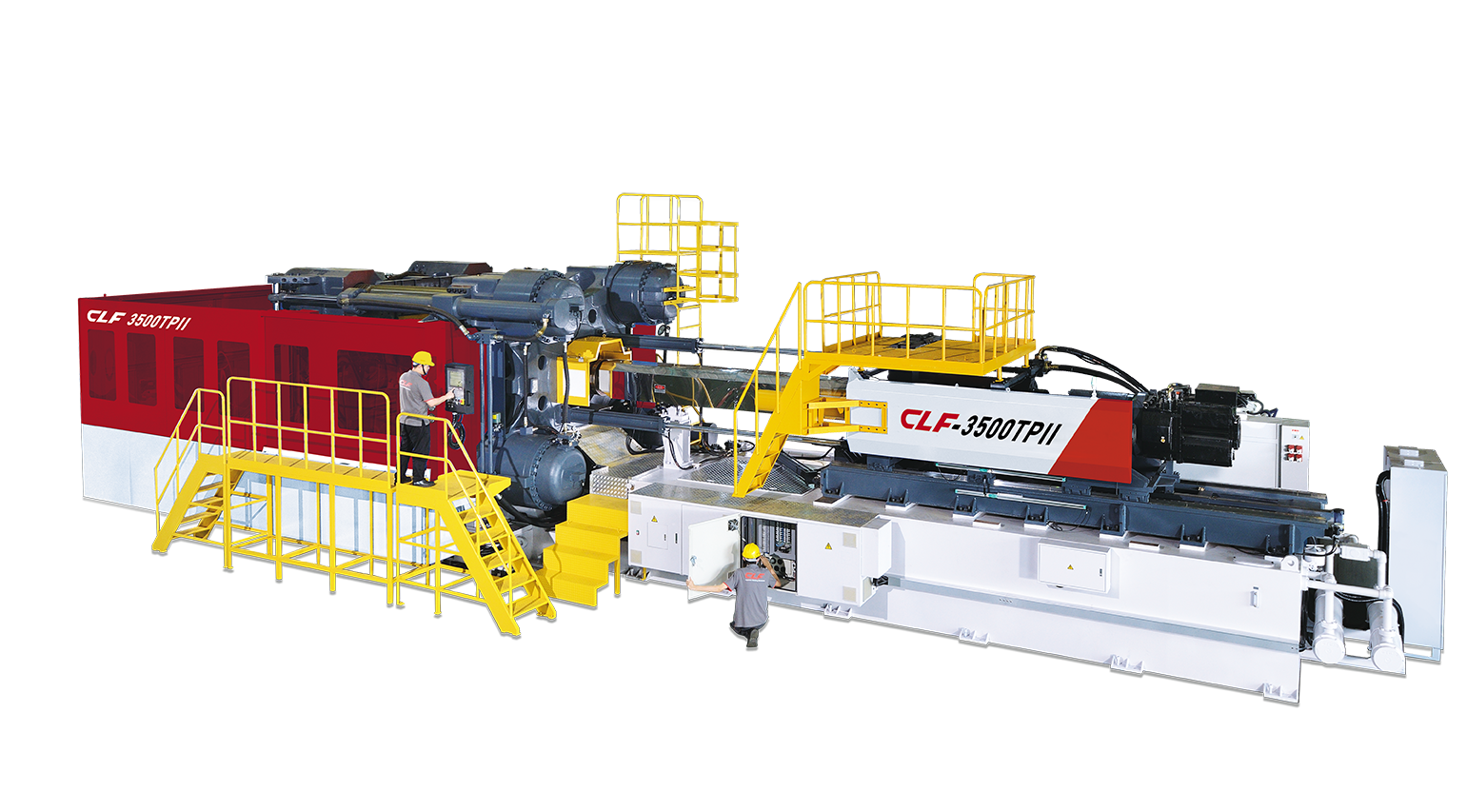

Chuan Lih Fa (CLF) Machinery Works Co. Ltd, a decades-old global manufacturer of diverse plastic injection molding machines, has lately made a breakthrough with their Two Platen Injection Molding Machine. CLF’s R&D team has successfully improved the cooling process and developed a multi-circular system, which resulted in an exceptionally high-speed cycle time.

Breakthrough - Successful Story in Taiwan

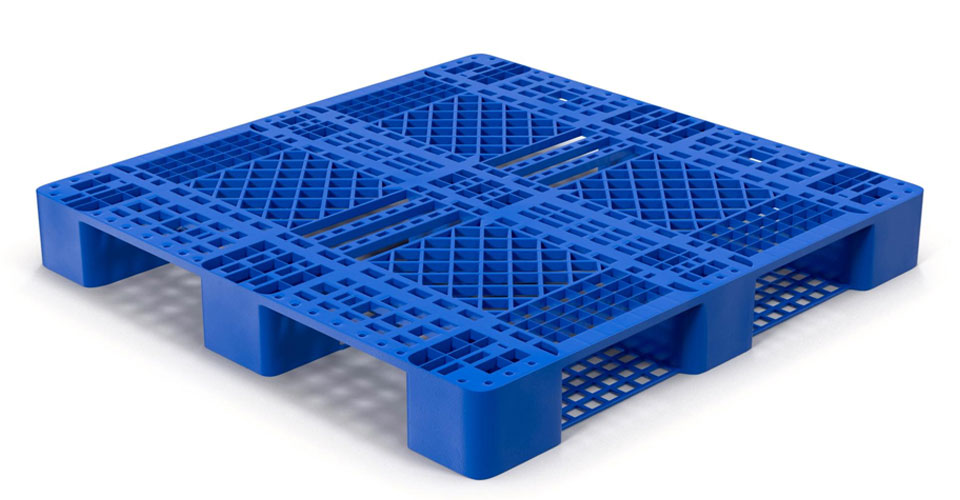

In the most recent successful case, the CLF's two-platen injection molding machine from the TPII Series has flawlessly accomplished the request of a Taiwanese customer, to reduce the injection molding cycle time in the production of large pallets. The CLF found out that the most time-consuming step of the production was cooling the mold, which could take up to 100 seconds to cool down, making one cycle over 150 seconds to complete. Thus, the R&D team began the project on the two-platen injection molding machine of the TPII Series, by using a better heat dissipation efficiency material like beryllium copper and re-designing the spacing of the mold cooling system, CLF has significantly decreased the cooling time. However, to further achieve the ultimate goal of reducing cycle time, they developed a multi-circular system, allowing multiple processes of production like feeding, molding, and storage to act simultaneously.

Moreover, this 3,500 tons injection molding machine has a unique two-platen design that greatly improves the clamping mechanism, reducing mold locking and pressure-generating time. With all these improvements and new features developed by CLF, the customer is now capable of producing an 11kg double-side pallet in an astonishing cycle time of 90 seconds.

Important Features You Need to Know

In addition, the latest TPII Series two-platen injection molding machine is more space-efficient, customized, and large mold capacity, while still maintaining incredible stability, precision, and durability. Its direct hydraulic locking mechanism eliminates the need for mechanical linkages, making this two-platen machine 20% shorter than other injection molding machines like three-platen machines.

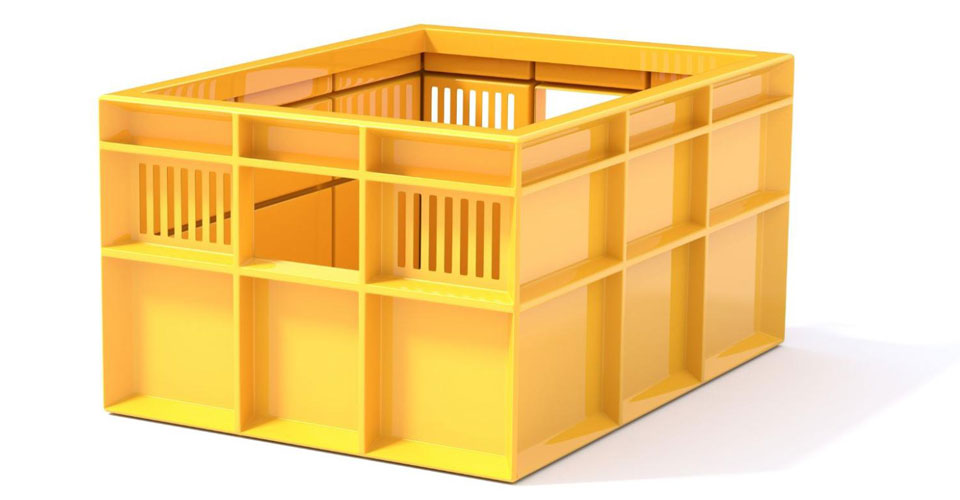

Hence, the TPII Series' clamping force, mold opening stroke, and distance between tie bars are highly customized, with its European standard control system increasing its scalability. Not to mention the spacious design between the platens allows for larger molds, which is perfect for producing large auto parts, large households, or logistic products. Additionally, the TPII Series is best known for its stability during the molding process, enhancing dimensional accuracy, and increased quality in products.

Meet Your Business Requirement

In conclusion, choosing a machine may take some time and effort. Optimal production efficiency and meeting the demands of a specific application depend on selecting the right machine. Several critical factors should be taken into account when making this decision, such as product size, energy efficiency objectives, cycle time, available space, and also budget constraints. Therefore, it is essential to thoroughly assess your business requirements and understand the applications of both machine designs before finalizing your equipment purchase.

Read more

- What Sets CLF Apart From Other Injection Molding Machine Manufacturers?

- CLF: Customized Injection Molding Machine for Automotive Parts and Components

- CLF: Consultant Expert for Plastic Injection Molding Machines!

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets