GENIUS: What to Consider When Choosing Melt Filters for Plastic Recycling Machines?

Melt Filter is an important component of Plastic Recycling Extrusion Machine. It helps to improve the end product's quality while also increasing production. However, as you are aware, not all melt filters for recycling and filtering post-consumer and post-industrial plastics are the same. They differ in terms of performance and price. If you want to buy an optimal melt filter for your plastic recycling extrusion machine, you should think about various variables before making your final decision. In this article, we will discuss 6 critical aspects that will assist you in selecting a dependable melt filter for your extrusion recycling machine and preventing it from creating a bottleneck in your recycling lines.

1. Your materials to be extrusion recycled

The type of melt filter you need depends on the material that is going to be recycled. If you are recycling unwashed post-industrial materials such as PVC, PET or HDPE, then you will require a different type of melt filter than if you are recycling washed post-consumer materials such as PP raffia, big bags or linear LDPE, HDPE packaging films. If your plastic feedstock contains higher comtainminations like labels, paper, wood or metal, then these must be removed through a fine mesh screen before being extruded into the pelletizing system. Any high contaminants presented in the plastic scraps will clog up your pelletizing system and reduce productivity dramatically if not eliminated entirely from the process flow.

2. Your required production output

Another factor that you need to consider for melt filtration is required output capacity. This will help you determine how much material you need to filter through each time you run it. If you have a high-production recycling machine and want to be able to keep up with demand, then you'll need a melt filter that can handle high volumes. If your recycling machine has a lower production rate and takes more time between runs, then you might be able to get by with less filtering capacity in order to save equipment costs.

3. Your required contamination level for final product

When choosing a melt filter for your plastic recycling extrusion machine, you need to ensure that it can handle the level of contamination and filtration requirements that your application requires.

The filtration requirement refers to how much impurity can be filtered out by melt filters for plastic recycling extrusion machines. If you have a lot of impurities in your plastic material and want to remove them as much as possible from your product, you need to choose a high-filtration melt filter for your extrusion recycling machine.

For example, if you are recycling plastic bags of food packaging, then you will need a more thorough filtration process than if you are recycling plastic bottles. Contamination level refers to how much contamination in the material being filtered out by the melt filter. If there is not much contamination in the material being filtered out, then a less rigorous filtration process will suffice.

4. Your extrusion screw diameter

Your extrusion screw diameter is also one of the factors to consider when choosing a melt filter for plastic recycling extrusion machines. This is because it will determine how much melt filtration you need and what type of filter you can use.

If you have an extrusion screw with a large diameter, then you will need a large filter that can handle the amount of melt that comes out of it. A small filter will not be able to do this effectively because it cannot hold enough liquid coming through it.

5. Your manpower

When choosing melt filters for your plastic recycling extrusion machine, it's important to consider the cost of labor. In the past, many machines required human intervention to change the filters out of necessity. But now, with self-cleaning filters becoming more popular, you can save time and money by automating this process. This is especially helpful if you're working in a large capacity or at a high volume and have multiple extruders running at once.

Automation can help increase efficiency and quality, save time and cost, and reduce the risk of human error. Self-cleaning melt filters are becoming one the trends for recycling machines. This will ensure that you get consistent results with each batch of recycled plastic.

6. The future maintenance costs

Maintenance costs should be as low as possible. The more reliable your recycling extrusion machine is, the less time and cost you'll have to spend fixing it. An important way to reduce maintenance costs is by having a filter that's easy to clean and maintain, which means it can be done by fixed operators in less time without tools. Another way of reducing maintenance costs is by having a self-cleaning melt filter for your recycling extrusion production.

Types of Melt Filters for Recycling Extrusion Equipment

Melt filters are used to filter out contaminants before the plastic enters the extrusion machine, and they can also improve the quality of the final product by removing impurities like label, paper, wood or metal. The main function of a melt filter is to remove certain types of contaminants from melted plastic, but there are many different types of melt filters with different filtering capabilities.

There are 3 main types of melt filters :

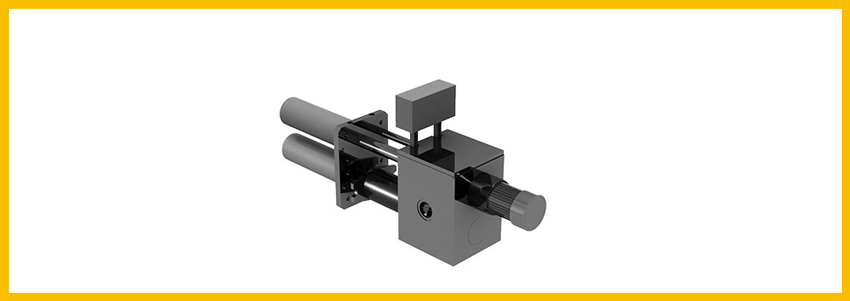

- Plate Filter : The first filter option is the plate filter, which is mostly preferable for the clean material recycling.

- Dual-Piston Filter : The second option is the dual piston filter, which is mostly suggested for the dirty material recycling. The system provides a wider filtration surface to reduce filter changing requirements and time spent. Moreover, while changing the filter screen one of the filters is always in the operation for continuous production.

- Self-cleaning Filter : The third option is the self cleaning filtration system, which saves time for manual screen changing of the filter. This filtration process can reduce residues by over 80% of the melted polymer.

The main differences are as below :

| Plate Filter | Dual-Piston Filter | Self-Cleaning Filter | |

| Labor Cost | Higher | Middle | Lower |

| Filtration Area | Smaller | Bigger | Continuously |

| Frequency of Mesh Change | Higher | Middle | Automaticly |

| Screen Monitor System | Automatic | Automatic | Automatic |

| Continuous filtration of the melt | N/A | N/A | Yes |

| Quality of final product | Fine | Better | Best |

| Reduction of Residues | Fine | Better | Best |

| Polymer lost | Higher | Middle | Lower |

We hope this article helped you understand what melt filters are and why they’re important for plastic recycling extrusion machines. If you have any questions or would like more information on the topic - melt filters, please don’t hesitate to contact us.

Original post: 6 FACTORS TO CONSIDER WHEN CHOOSING MELT FILTERS FOR PLASTIC RECYCLING EXTRUSION MACHINES