Issue 166

Souscrire

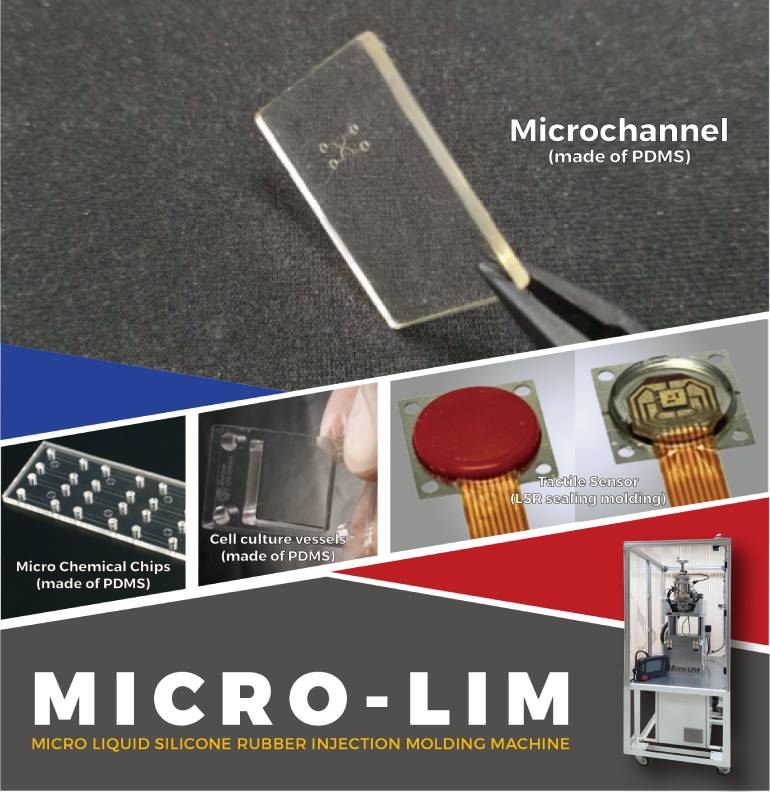

Liquid Silicone Rubber Injection Molding Machine Presented by ANNTONG. Applied to LSR & PDMS & EPOXY Without Dosing System Equipment.

The applications of Liquid Silicone Rubber (LSR) have gradually increased due to its excellent property and weather ability. We provide the high-performance LSR cold runner system and cold deck to the industries in the electronics and appliances, construction, automobile, and medical products, etc. The commonly used products include pacifier, medical equipment, kitchen utensil, headset, buttons, seals and dive masks, etc.

We provide the Micro-LIM without LSR dosing system equipment, which can not only save your equipment cost, but also make samples quickly. “Micro-LIM” is a high precision injection molding machine that can perform injection molding of transparent high-purity liquid silicone rubber (PDMS). The molding operation is completed in 3 minutes, achieving overwhelmingly superior productivity compared to casting.

.Injecting molding of “Liquid Silicone Rubber” or “Low-Viscosity & High-Clear PDMS” is possible.

.Can be performed the injection molding process without the dosing system.

.Precision molding based on precise weighing by power-driven plunger a unique shut-off valve.

.Far more excellent productivity in PDMS molding compared to casting.

.Compact in size & excellent in maintainability. It can be set up in clean booth in your laboratory.

.Molding produced in small quantities of resins (100g):It's ideal for special & expensive materials tests.

.Capable to mold other thermosetting liquefied materials (epoxy or acrylic systems) well.

Main Specifications:

.Mold Clamping Force:2 ton

.Dimensions:W495 x D530 x H915 (mm)

.Target Materials:LSR, PDMS, EPOXY

.Drive:Motor, Air

.Control:3 Speed rates, 2 Pressure setting, Position / Pressure switchover control, etc.

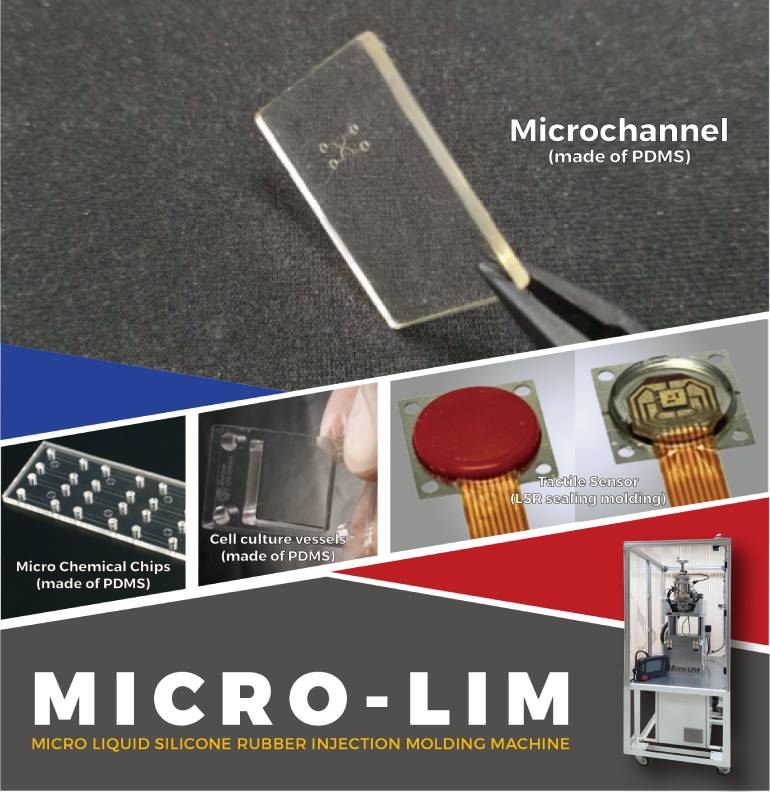

We provide the Micro-LIM without LSR dosing system equipment, which can not only save your equipment cost, but also make samples quickly. “Micro-LIM” is a high precision injection molding machine that can perform injection molding of transparent high-purity liquid silicone rubber (PDMS). The molding operation is completed in 3 minutes, achieving overwhelmingly superior productivity compared to casting.

.Injecting molding of “Liquid Silicone Rubber” or “Low-Viscosity & High-Clear PDMS” is possible.

.Can be performed the injection molding process without the dosing system.

.Precision molding based on precise weighing by power-driven plunger a unique shut-off valve.

.Far more excellent productivity in PDMS molding compared to casting.

.Compact in size & excellent in maintainability. It can be set up in clean booth in your laboratory.

.Molding produced in small quantities of resins (100g):It's ideal for special & expensive materials tests.

.Capable to mold other thermosetting liquefied materials (epoxy or acrylic systems) well.

Main Specifications:

.Mold Clamping Force:2 ton

.Dimensions:W495 x D530 x H915 (mm)

.Target Materials:LSR, PDMS, EPOXY

.Drive:Motor, Air

.Control:3 Speed rates, 2 Pressure setting, Position / Pressure switchover control, etc.

|

| Official Website https://www.anntong.com.tw/en/index.html ANNTONG in PRM-TAIWAN https://www.prm-taiwan.com/com/anntong.html |

E-News Categories

Machines de moulage par soufflage

- Machine de soufflage automatique

- Machines de moulage par soufflage

- Machines de moulage par soufflage par extrusion continue

- Machine de moulage par soufflage par extrusion

- Machines de moulage par soufflage par extrusion

- Machine de moulage par soufflage entièrement électrique

- Machines hydrauliques de moulage par soufflage

- Machine de moulage par soufflage en plastique

Extrudeuses et lignes d'extrusion

- Ligne d'extrusion de film à bulles d'air

- Ligne d'extrusion de film à bulles d'air

- Ligne de co-extrusion de feuille de bulle d'air

- Machines de fabrication de sacs

- Machine de fabrication de film de soufflage

- Souffler Film Exusion

- Machine de fabrication de film soufflé

- Machine de film de fonte

- Machine de revêtement

- Ligne d'extrusion de feuille de mousse d'ENV / EPE

- Extrudeuse

- Machines à plastifier

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Machines d'extrusion de monofilament

- Ligne d'extrusion de monofilament

- PET Strapping Band Extrusion Lines

- Machines de fabrication de sacs en plastique

- Co-extrusion de film plastique

- Machines de fabrication de tuyaux en plastique

- Machine de fabrication de tubes en plastique

- Tuyau de PVC faisant la machine

- Machines de fabrication de paille

- Extrudeuse à double vis

- Extrudeuses à double vis

- Sac tissé faisant la machine

Machines de moulage par injection

- Machines électriques de moulage par injection

- Machine d'injection horizontale

- Machines horizontales de moulage par injection

- Machines de moulage par injection

- Moulage par injection précis

- Machines de moulage par injection à deux plateaux

- Machine d'injection verticale

- Machines verticales de moulage par injection

Équipement de recyclage pour le prétraitement

- Ligne de lavage de bouteilles

- Broyeur

- Granulateur

- Pelletiseur

- Pelletiseurs

- Pelletizing Machines

- Ligne de recyclage de bouteilles PET

- Ligne de lavage à chaud en PET

- Machine à granuler

- Équipement de recyclage de plastique pour le prétraitement

- Machines de recyclage de plastique

- Machine de recyclage des déchets plastiques

- Lignes de recyclage

- Machine de recyclage

- Shredder

- Squeezers

- Corde à linge

- Équipement de recyclage des déchets