Machines de moulage par soufflage

HOT NEWS

CHEN WAY: 4 Must-Know Tips to Cost Saving and Eco-Friendly of Blow Molding Machine

In the case of extrusion blow molding, companies around the world look for ways to start eco-friendly and cost-saving production. This article will therefore let you know some must-know tips to achieve this. Why should a blow molder care for sustainability?

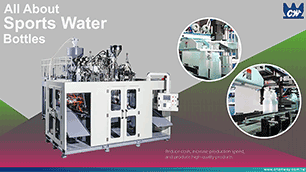

CHEN WAY: How is a Sports Water Bottle Made by Extrusion Blow Molding?

When we talk about everyday use products, we can mention different examples such as sports water bottles, which are in almost everyone's daily life: besides ensuring individuals stay hydrated throughout the day, they also eliminate the need for disposable, single-use bottles which are known for polluting the oceans.

CHEN WAY - 3 Simple Secrets for Ecofriendly and Cost Saving Blow Molding

One thing that makes blow molding so great are its endless applications. In fact, plastic products are everywhere, making it clear how incredibly useful this material is in modern life. However, in today’s world, the production of these products is not just a matter of their unit price, quality, or visual appearance; customers and end users also care about their sustainability, and they care a lot.

LONG CHANG: Single Body Oil Hydraulic Compression Molding Machine - FC Series

Long Chang offers high-efficiency and top-notch post-sales service to accomplish customer needs by our experience and hard-working team. With more than 40 years experience in the field of injection molding, LONG CHANG can offer not only a wide range of high quality injection molding machines for different plastic industries and molding solutions, but integrated turnkey project for end users.

CHEN WAY - Top 6 Common Problems in HDPE Blow Molding

HDPE Blow Molding is the most economical- highest production output forming process for hollow products: beverage, chemical or pharmaceutical bottles, edible oil jerry cans, chemical drums, etc. And even though you can produce an almost perfect, high quality container, you might encounter different problems along the blow molding process of your products, so it is vital that you can identify where the problem comes from and how to handle it.

5 Minutes to Know HDPE Blow Molding

HDPE Blow Molding is the process of molding a softened thermoplastic hollow form called a Parison, by inflating it against the cooled surface of a closed mold, the expanded plastic then solidifies into a hollow product that needs very little to none finishing processes after the Blow Molding.

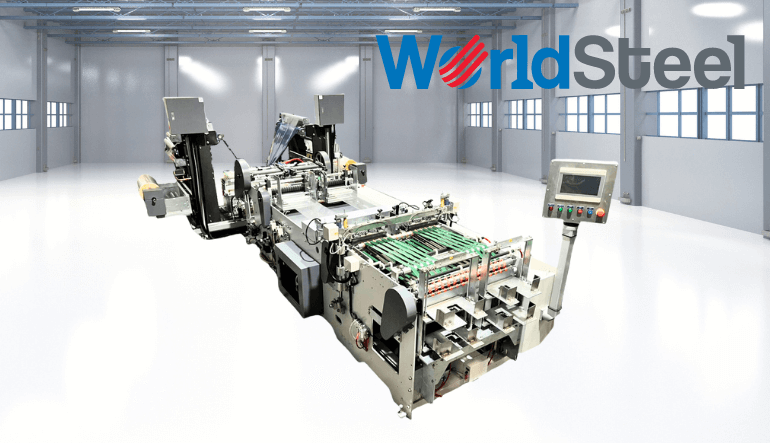

FULL SHINE: Blow Molding Machines with High Production Efficiency, High Quality and Lower Cost

FS-90PLDO from Full Shine Plastic Machinery (TAIWAN) is your best choice for the pursuit of highly productive blow molding machine

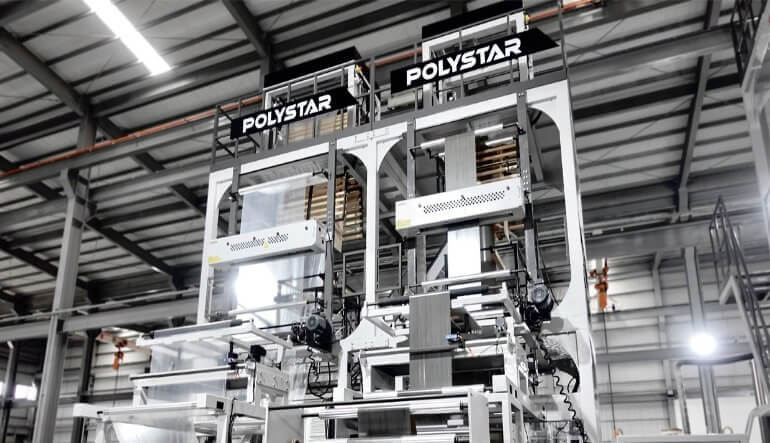

CHIA MING: Our Machines Now Go SMART

In response to the trend of environmental protection and the demand for less energy consumption, CHIA MING is pleased to provide a fully electric co-extrusion blow molding machine model CM FE90.55FVH2D