LATEST UPDATE Souscrire

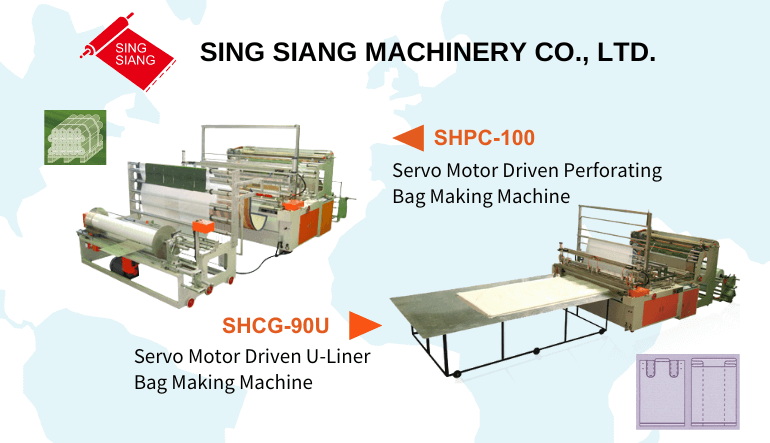

SING SIANG Always at the Forefront of Bag Making Machines Technology

SING SIANG Machinery Co., Ltd. (SSM) is established in 1975 in Taiwan, specialized in all kinds of bag making machines, always provides customers with the most comprehensive technological service. Based on more than 30 years of design and manufacturing experience, SSM is capable of design machines with practical performance for the customer, at a reasonable and competitive price.

BoReTech: Wastewater Treatment System Enabling Green Production for Plastic Recycling Facilities

Through the recycling of waste plastic, materials are reintroduced into the production cycle, achieving a “resource-product-waste-recycled resource” loop that prolongs plastic lifespan and effectively reduces the need for landfill and incineration. By recycling plastics, greenhouse gas emissions are decreased, contributing to the mitigation of climate change. As the plastic recycling industry advances, it paves the way for new technologies, plastic, and industries, promoting green innovation. However, with increased plastic recycling comes the critical task of addressing the wastewater treatment during the plastic recycling process.

Essential Tips for Choosing the Best PVC Pipe Extrusion Line

Selecting the right PVC Pipe Extrusion Line for producing high-quality pipes is a critical decision for any manufacturing operation. It affects production efficiency, product quality, and long-term profitability. Before getting overwhelmed by the numerous options available, it’s important to focus on evaluating key factors. This comprehensive guide will highlight essential considerations to help you make an informed choice.

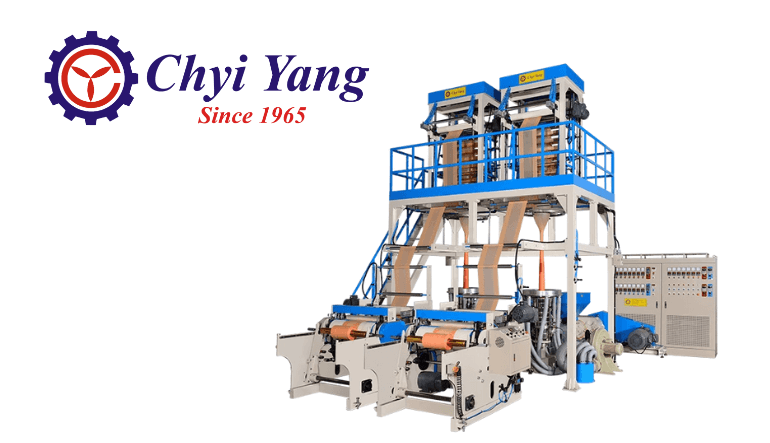

Advantages of ABA Co-extrusion Blown Film Machine

A co-extrusion process uses more than one polymer to form the plastic bubble and therefore more layers to the film. The most prevalent blown film process today is the ABA co-extrusion process. One of CHYI YANG's most popular machines is also the ABA co-extrusion blown film machine. The term ABA indicates the three-layer structure of the film, two outer layers, and one inner layer, hence ABA. The materials of the A layer and B layer are different. The outer layer typically uses new materials, whereas the inner layer uses recycled materials. Using more than one material leads to several advantages and installation adjustments on the ABA blown film machine. As a leading plastic film machinery manufacturer in Taiwan, today CHYI YANG will talk about the advantages of this kind of blown film machine and how it can help your business.

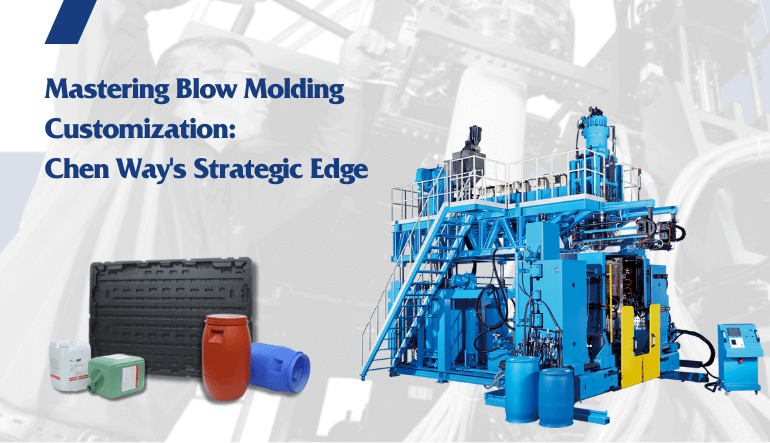

Mastering Blow Molding Customization: Chen Way's Strategic Edge

In the dynamic world of manufacturing, the ability to offer tailored solutions that meet specific client requirements is a significant competitive advantage. Chen Way Machinery (進韋機械), a leading player in the Plastic Blow Molding machinery sector, exemplifies this capability through its extensive range of products and exceptional customization services. This article delves into Chen Way Machinery's offerings, success stories, and the factors that make it a preferred choice for international machinery buyers.

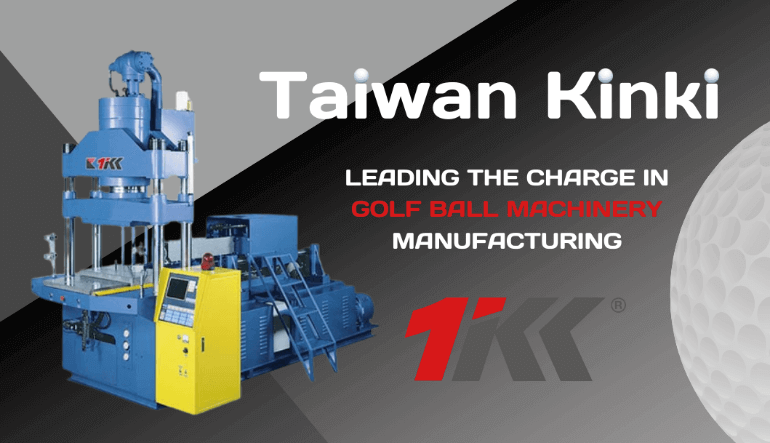

Taiwan Kinki: Leading the Charge in Golf Ball Machinery Manufacturing

As golf continues to surge in popularity worldwide, Taiwan has firmly established itself as a pivotal hub in the global golf ball industry. According to the Ministry of Finance's 2023 statistics, Taiwan’s golf ball exports have captured over 30% of the global market share, with export revenues soaring to $710 million. Amidst this thriving landscape stands Taiwan Kinki (台灣今機), a trailblazer in high-precision golf ball machinery, poised to become the preferred partner for international buyers seeking top-tier production equipment.

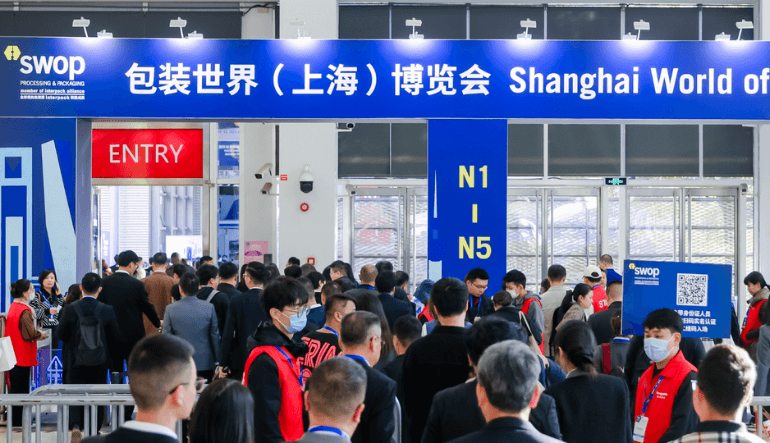

swop 2024: Leading Innovation in Packaging — A New “Buyer’s Perspective” Experience to Launch This November

The Shanghai World of Packaging (referred to as “swop”), co-organized by Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd., is set to return in full force from November 18-20, 2024, at the Shanghai New International Expo Center.

Revolutionizing the Market: CHYI YANG's Smart 5/7-layer Blown Film Machines Lead the ESG Sustainability Trend

Chyi Yang's Smart 5/7-layer Blown Film Machines revolutionize plastic film production, reducing costs and material waste while complying with regulations. Their Auto-recycling blown film machines use precision formula calculations and advanced recycling mechanisms to improve production yield and achieve "ZERO WASTE" while reducing energy consumption to improve competitiveness.

From Waste to Worth: Genius Machinery’s Green Engineering

GENIUS Machinery is renowned globally in the plastic recycling machinery market for its advanced technology and customized solutions. Ever since it started, GENIUS has not only focused on environmental protection and the circular economy but has also been dedicated to comprehensive factory planning for plastic recycling systems. With over 40 years of experience in the design and manufacturing of recycling machinery, the company offers a complete range of solutions, including plastic washing lines, recycling machines, pelletizers, squeeze dryers, crushers, and shredders. Worldwide Market Deployment: Strengthening Global Presence

PE Cling Film Market Trend: Sustainability and Clean Production

The use of cling film has substantially expanded in recent years in response to the increased demand from global pharmaceutical and F&B industries. This is especially true considering that manufacturers have developed many special-purpose films to boost market appeal. North America currently dominates the cling film market; however, the market for cling film has become a hot spot for rapid growth due to the urbanization of developing regions in the Asia Pacific, including China, India and Southeast Asia.

Mastering PVC Twin Screw Extruders: Your 3-Minute Essential Guide

PVC Twin Screw Extruders are a type of plastic processing machine that melts, blends, and incorporates PVC resin into a homogeneous melt. The melt is then extruded through a die to form the desired shape of the final product, such as pipes, profiles, films, sheets, or foams. This guide provides a comprehensive overview of PVC Twin Screw Extruders, covering their process, key components, applications, and how to choose the right one for your needs.

How to Choose the Right POLYSTAR Recycling Machine Based on Your Plastic Waste?

Follow the guidelines to choose the right POLYSTAR plastic recycling machine that processes your plastic waste efficiently and with a high yield.