LATEST UPDATE Souscrire

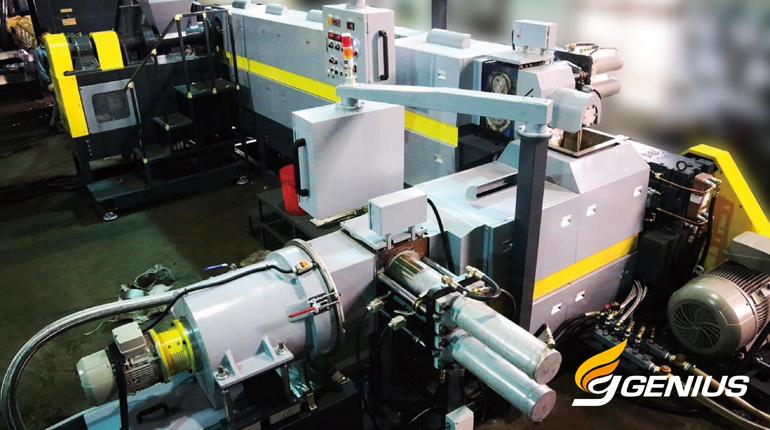

GENIUS: How to Recycle Waste from Electrical and Electronic Equipment (WEEE)?

Recycling of WEEE (Waste from Electrical and Electronic Equipment) is a rising issue in the global recycling market. Such as the amount of waste electrical and electronic equipment created every year in the European Union is increasing rapidly as the fastest growing waste streams. Based on European Commission, 5 tonnes of waste is produced by the average European each year. Only 38% of waste in the EU is recycled, and over 60% of household waste still goes to landfill in some EU countries.

KING'S - Trend In Global 5-Gallon Water Bottles Market By 2026

According to the forecast of BlueWeave Consulting, the valuation of the global 5-gallon water bottle market will increase from US$7856.88 million in 2019 to US$10,234.50 million in 2026. During the forecast period from 2020 to 2026, the compound annual growth rate is 2.2%.

HCI Provides Latest Technology of Medical Sterilization Pouch / Reel Making Machine

Global demand for medical packaging continues to grow, quality standard expected of the sterile pouches/ reels also set to increase and become more stringent. HCI is aware of this trend and has since collaborated with MNCs to make critical changes to its medical pouch making machine to meet this new standard. More operator oriented features, stable and reliable machine with more precise temperature control are the key.

Chao Wei - Multi-function Side Sealing Machine: CW-PFM-SV

CW-PFM-SV series are special designed versatile machines which can produce several types of bags, Soft Loop Handle Bag, Draw Tape Bag, Die Cut Bag & Patch Handle Bag. They are very beneficial for the customers as they will help to save on investing different machines for these different types of bags.

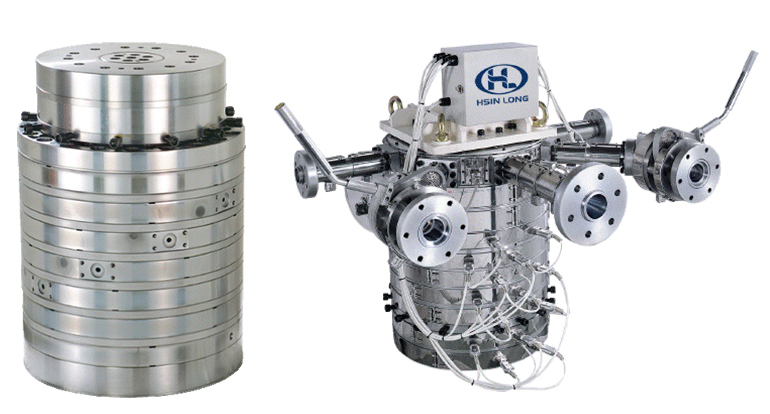

HSIN LONG- Innovations for Optimal Solutions

HSIN LONG, one of the leading manufacturers of Blown Film Die Head Industry, has been forging its outstanding reputation for over 50 years. Hsin Long began as an OEM cooperating with Taiwanese companies who could supply different components to their customers.

Italian FIMIC melt filter provides automatic melt filter solution for customers in Asia

The Italian company FIMIC, which provides automatic self-cleaning filter to plastic recycling industry, participated Chinaplas for the very first time.

TAIWAN KINKI at CHINAPLAS 2021

Faced with CHINAPLAS, which has been delayed for one year, Taiwan Kinki benefited from the establishment of factories in Dongguan and Ningbo on the mainland in 1991. It not only took over the Chinese market in the third quarter of last year, but also rebounded due to rapid response to the early termination of the supply chain phenomenon.

SHINI - The Case of Whole Plant Planning in Protective Appliances Industry

Shini is continuously supporting its customers and cherish their successful stories that the customers add value to the industry despite of the current outbreak. In this article we would like to share about one of our customers' case story from China.

Chinaplas 2021: ENGEL at Industry 4.0 – Factory of the Future

How can consistently high product quality be maintained in the face of fluctua-tions in raw material? How can high machine availability and productivity be ensured even in the face of travel restrictions?

Fast Delivery and Simple Installation of Recycling Machine - A Clear Advantage for Film and Bag Producers

Multiple sets of recycling pelletizing extruders Repro-Flex have been installed in South Africa in the year of 2020, mainly for film producers and bag converters of LDPE, HDPE, PP and BOPP who process their post-industrial (factory) waste in-house.

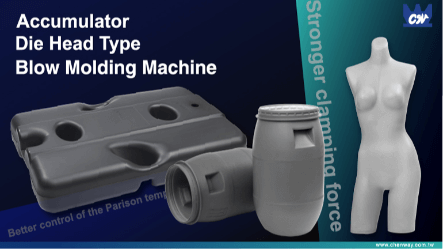

CHEN WAY: 5 Minutes to Know HDPE Blow Molding

What is HDPE Blow Molding? HDPE Blow Molding is the process of molding a softened thermoplastic hollow form called a Parison. This Parison is first vertically extruded from the Die Head of a Blow Molding Machine and then, it is inflated against the cooled surface of a closed mold, the expanded plastic then solidifies into a hollow HDPE product that needs none or very little finishing processes after the Blow Molding.