LATEST UPDATE Souscrire

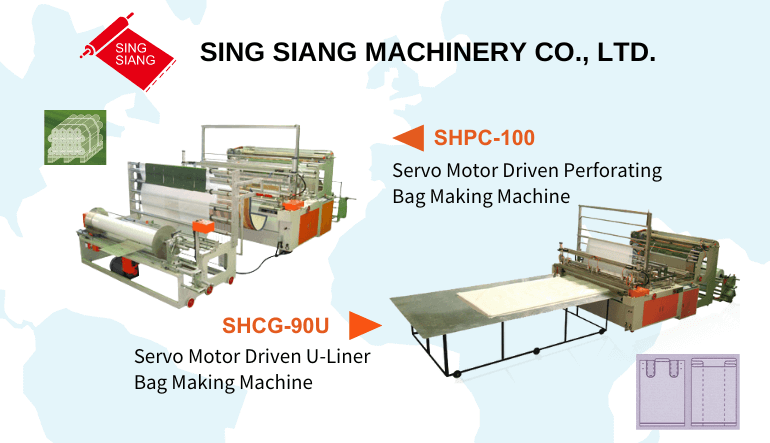

SING SIANG Always at the Forefront of Bag Making Machines Technology

SING SIANG Machinery Co., Ltd. (SSM) is established in 1975 in Taiwan, specialized in all kinds of bag making machines, always provides customers with the most comprehensive technological service. Based on more than 30 years of design and manufacturing experience, SSM is capable of design machines with practical performance for the customer, at a reasonable and competitive price.

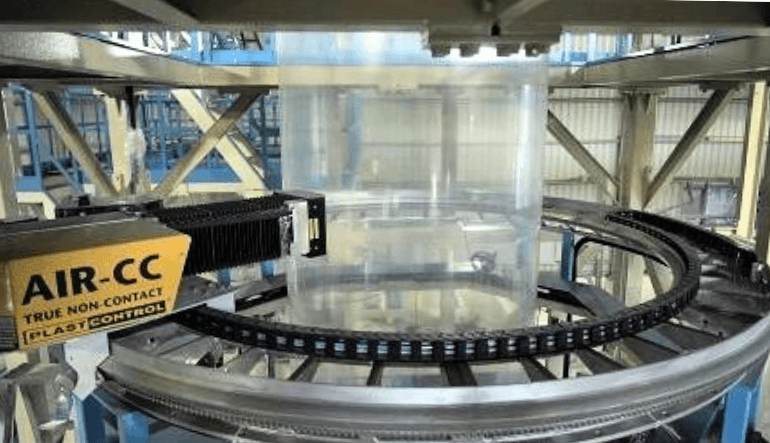

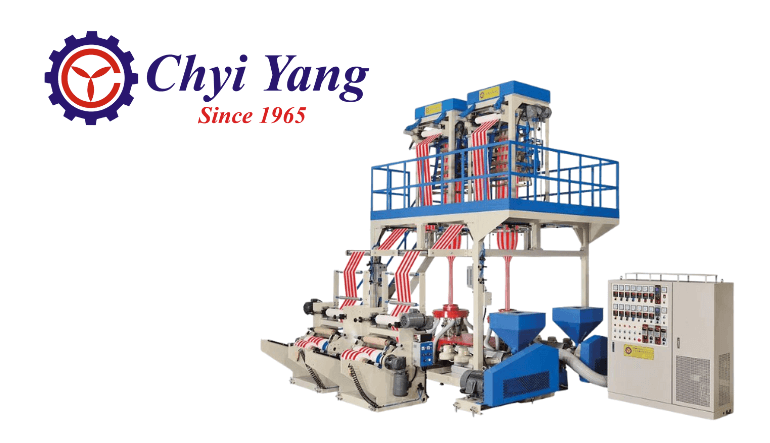

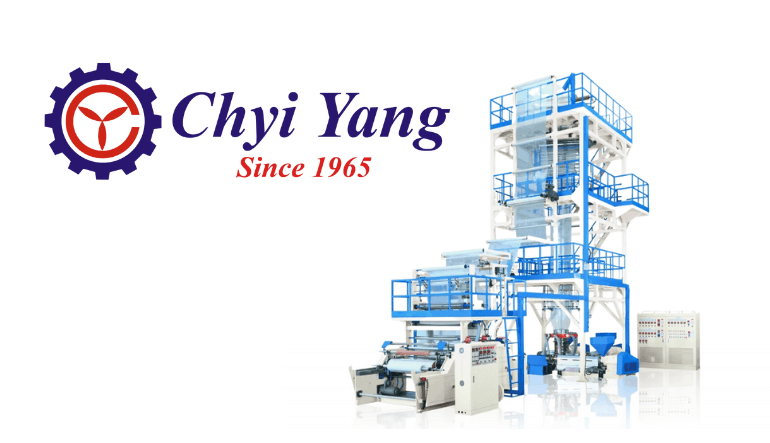

Meet Your Needs for Stable Thickness, High Productivity & Multilayer Quality with CHYI YANG Blown Film Machine

The global ESG trend is forming, and corporate sustainability will become a "standard" for businesses. As the European Union takes the lead in announcing the 2030 carbon reduction target, countries follow suit, and the plastic film industry is also contributing to the trend of sustainable development.

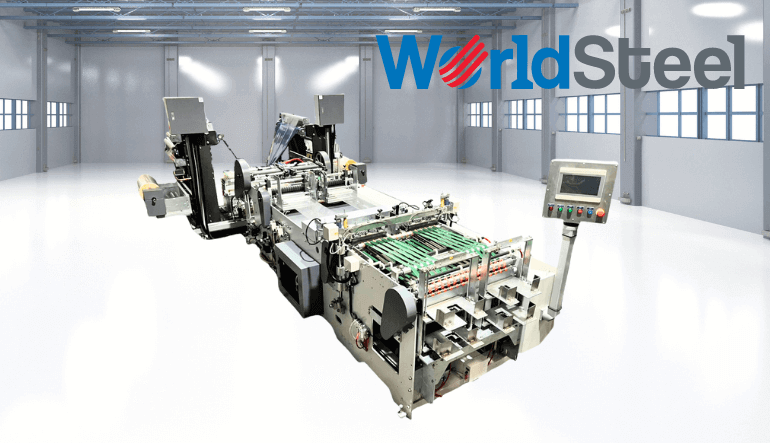

WORLD STEEL: Build Your Flexible Production Line

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, we have the best engineering crew in the industry to provide total solutions which include design, customization and development. To meet customer needs, we are committed to developing new models and increasing product competitiveness.

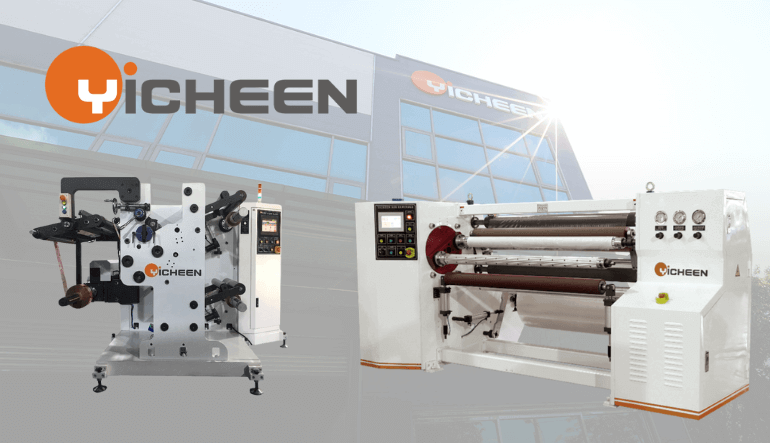

YICHEEN: Multifunctional Slitting Machine – The Importance of Post-Processing in the Flexible (Plastic) Packaging Industry

Understanding the Principle of Operation To fully leverage post-processing equipment in the flexible (plastic) packaging industry, it is crucial to understand its working principles. The post-processing slitting machines in the flexible (plastic) packaging industry primarily deal with two main types of materials: 1. Plastic tape / 2. Plastic film.

Plastic Drums and Plastic Drum Machines: A Quick Guide

Blue HDPE plastic drums are very common containers in warehouses and transport facilities across the world. These sturdy and durable containers are not only cost-effective but also incredibly useful when it comes to the safe and secure storage and transport of many different industrial goods. Given their popularity, plastic drum-making machines are also in constant demand by customers who seek effective solutions for their industrial businesses.

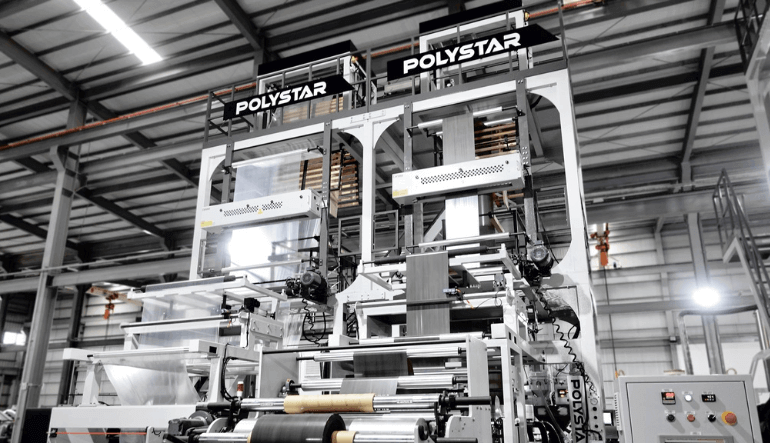

Optimized Blown Film Technology: Keys to Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. POLYSTAR's blown film extruders are designed to be operationally stable and easy to use. Additionally, by optimizing extrusion screws and die heads, our machines empower manufacturers to adopt sustainable materials like recycled pellets, and CaCo3. Let’s take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging!

Do You Know the Invisible Champion Who Can Assist You Enter into the Cling Film/Wrapping Film Market with Ease?

How do we make PE cling film that is non-toxic, breathable, and easy to tear and break? Ask Chyi Yang, the company that provides a complete plant solution that enables beginning manufacturers to enter the PE cling film/wrapping film market with just one machine, allowing them to cope with the unpredictable market environment easily.

Super High Speed HDPE Capacity Blown Film Machine in Less Space

Chyi Yang showed one set “Two Stripes & Two dies Co-Extrusion Blown Film Machine” in Andina-Pack 2015 Colombia exhibition. This machine is equipped with two dies & two extruders to produce two stripes T-shirt bags for market using. The two 45mm extruders provide two dies to have 2-line film rolls at one time. Forced feeding extruders offer you bigger capacity, the max. capacity is 140kgs/hr. for 550mm film width at 20micron film thickness. You can get max. 70kgs/hr. from each winder, and max. 140kgs/hr. from two winders.

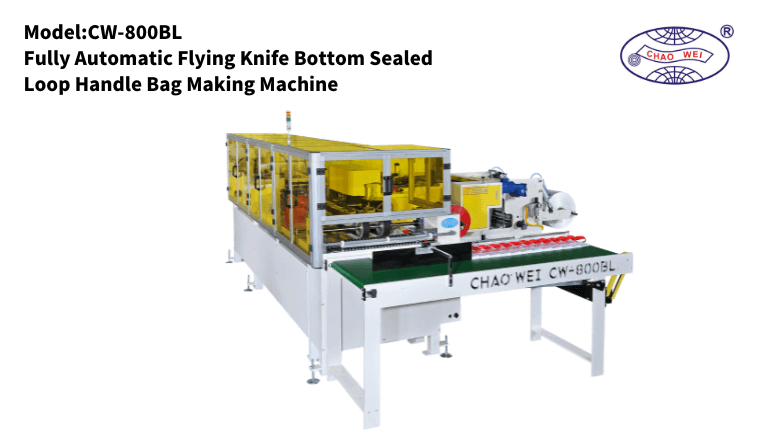

CHAO WEI: Bottom Sealed Loop Handle Bag Making Machine

CW-BL is for bottom sealed loop handle bags at maximum speed 50 bags/min.

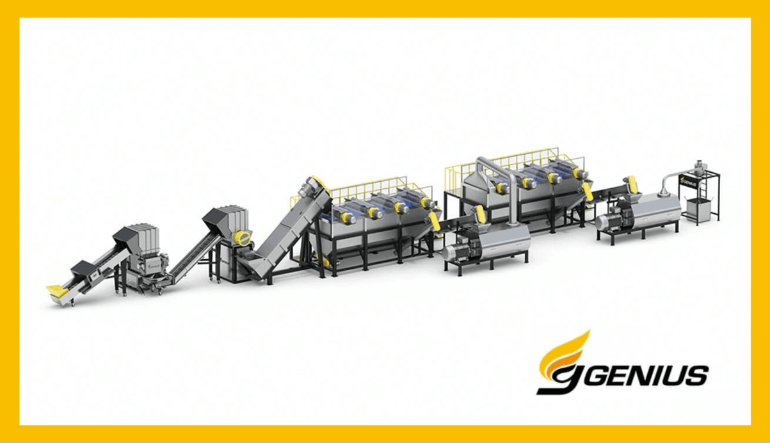

Essential Types of Plastic Recycling Machines for Efficient Waste Management

Plastic recycling is essential for addressing the waste crisis and reducing environmental impact. Beyond waste reduction and resource conservation, a significant advantage is the substantial decrease in carbon emissions achieved by diverting plastic from landfills and incineration. Recycling processes inherently involve lower energy usage, resulting in decreased carbon emissions. To enhance efficiency and maximize environmental benefits, integrating advanced technologies like plastic recycling machines, including Plastic Extruders, Shredders and Granulators, Plastic washing Lines, and Plastic Pelletizers are crucial. These mechanized systems automate and streamline the recycling process, making it more economically viable and scalable.

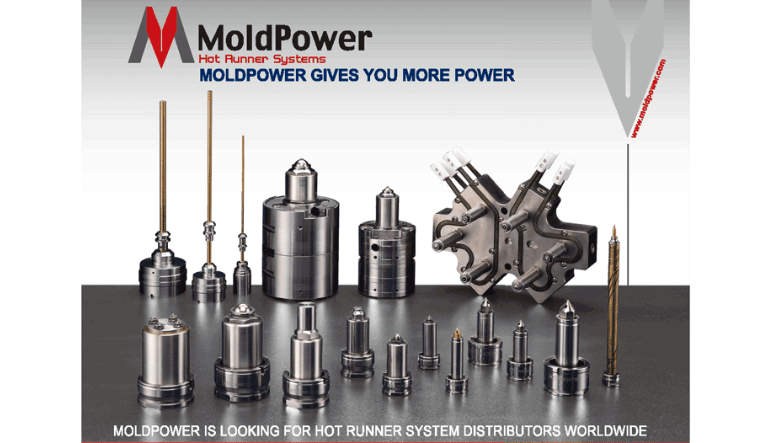

MOLDPOWER is Looking for Hot Runner System Distributors Worldwide

In 1997, Mr. Chen, Chung-Le and Mr. Chen, Ya-Mo co-founded Mold Power Co. Our core-values are honesty, quality, expertise, and a better future together. We are devoted to the design and the manufacturing of hot runner systems and originated the brand “Mold Power”. Because of our superior product performance, our products have been adopted by quite a few domestic mold plants for appliances, food containers, cosmetics, automotive parts, medical supplies, electronic products etc.. We provide customers with complete products and technology sharing.

How Can High Quality be Produced Consistently out of Complex Formulations?

The blown film market is evolving in an increasingly fast pace to meet the highly diversified, large-volume and variable material requirements of industries and emerging applications. Bag manufacturers and packaging material producers must use blown film machines with hardness, corrosion resistance, and durability to achieve consistently high yields while maintaining quality. More important goal is meeting the demands in film processing with complex characteristics such as those for agricultural films, cover films, laminated films, grain and dry food packaging, medical packaging and other critical packaging.