LATEST UPDATE Souscrire

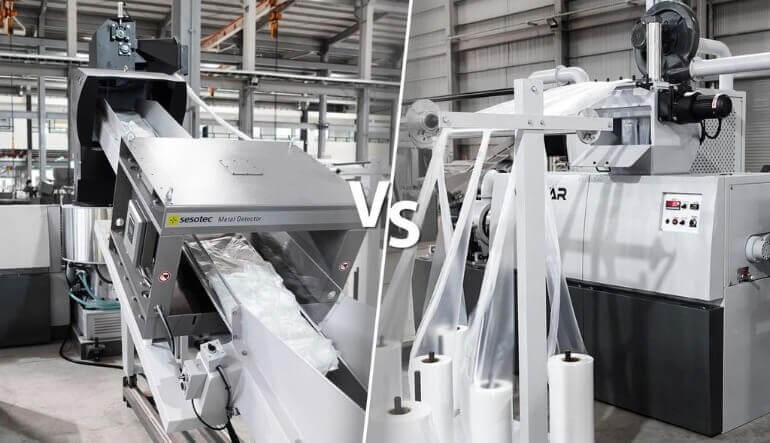

Plastic Pelletizer Comparison for In-house Plastic Film Recycling

In-house plastic film is usually clean and can be reprocessed right away without extra procedures. But what kind of recycling equipment you should invest in to make the best use of it? For in-house plastic film recycling, POLYSTAR has two recommended solutions: the Cutter-compactor Plastic Pelletizer, Repro-Flex, and the Air-cooled Plastic Pelletizer, Repro-Air. Both recycling machines can process HDPE, LDPE, and LLDPE clean post-industrial plastics like film, bags, T-shirt bag cut-offs, and edge-trim waste. However, Repro-Flex can deal with more kinds of plastics such as PP, PS, PA, etc. Let’s take a closer look at what they feature and their advantages, which are the main differences between them.

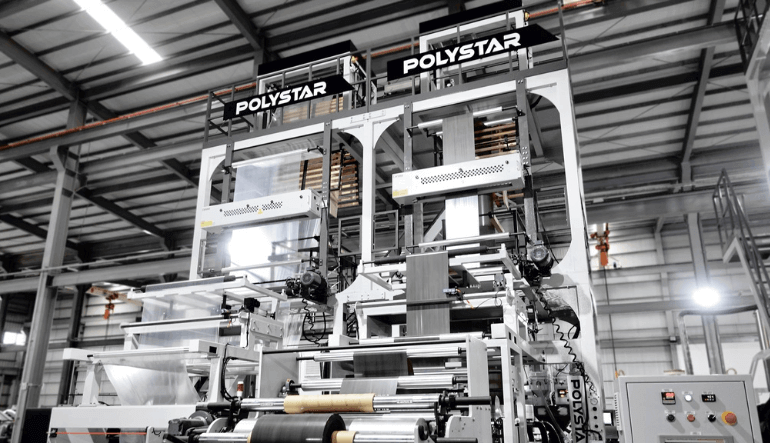

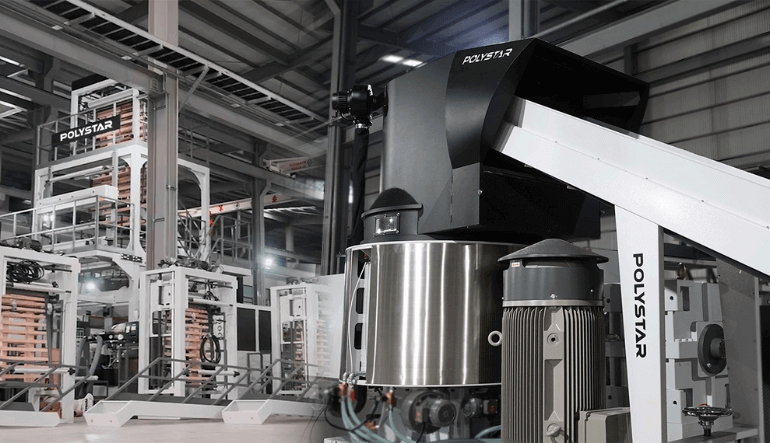

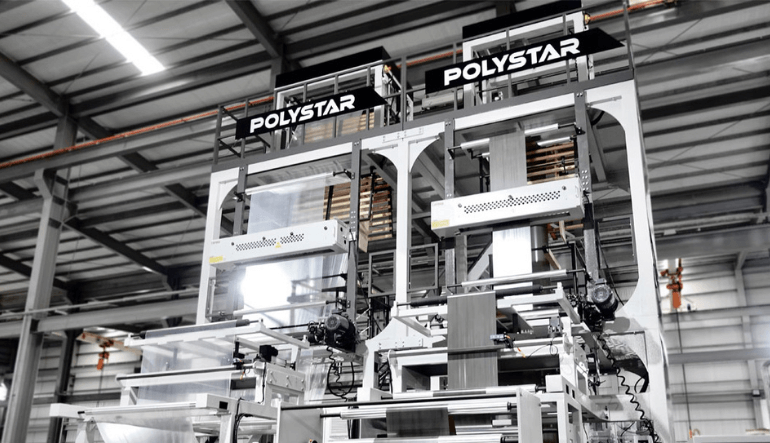

Optimized Blown Film Technology: Keys to Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. POLYSTAR's blown film extruders are designed to be operationally stable and easy to use. Additionally, by optimizing extrusion screws and die heads, our machines empower manufacturers to adopt sustainable materials like recycled pellets, and CaCo3. Let’s take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging!

POLYSTAR Recycling Machines Turn Waste into Profit

In the first quarter of 2024, POLYSTAR traveled to various countries worldwide for installations, maintenance, and exhibitions. We had the pleasure of meeting one of our biggest customers in the US. In this article, we'll take you through their successful journey of integrating our plastic recycling technologies and achieving success in the industry. If you're interested in our plastic recycling machines, be sure to catch us at these upcoming exhibitions for our innovative plastic recycling solutions

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

Flexible POLYSTAR Blown Film Extruders for Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. Let's take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging.