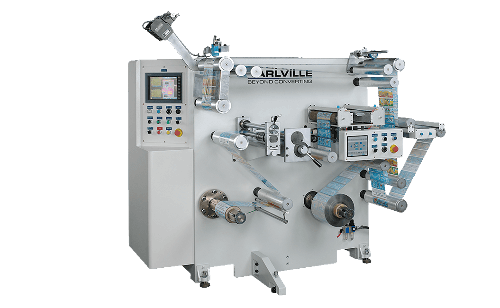

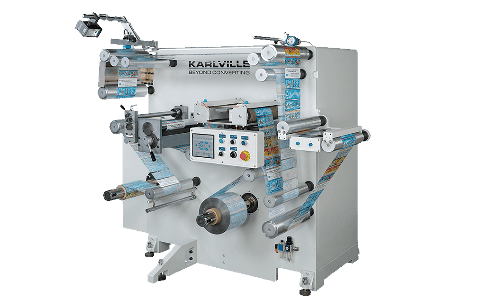

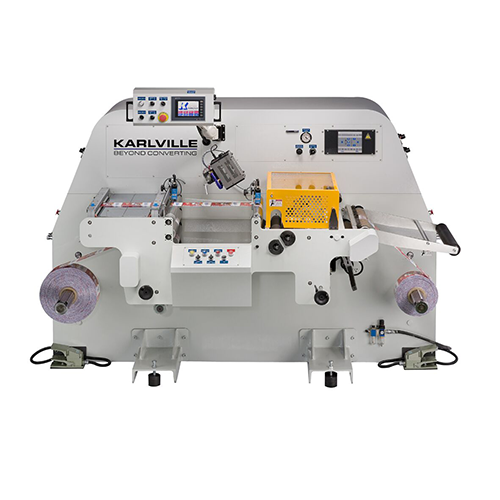

Classification: Coupe étroite et inspection

Pays: Taïwan

Téléphone: 886-4-23587272

Fax: 886-4-23580882

Personne de contact: Vicky Chen

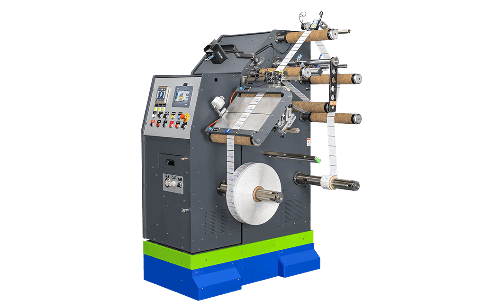

- Film Accumulation

- Unilux Strobe & Operator View Table

- Shear Knifes

- Single Rewind Shaft

- Air Shafts

- Digital Edge Guide

- Unwind & Splice Table

- Foot Pedals

- Touch Screen

- Web Gripper

| Model | ProLabel |

|---|---|

| Materials | Self Adhesive Label Stock |

| Available widths | 350mm/450mm |

| Speed | 300 meters per minute |

| Unwind diameter | 700mm / 1000mm |

| Rewind diameter | 500mm |

| Core sizes | 1- 6” standard 3” (76”mm) |

| Unwind splice table | Standard |

| Unwind tension system | Auto control by calculation |

| Unwind shaft | Cantilever air shaft |

| Unwind tension control | Powder brake |

| Unwind edge guide | E+L Germany – ultra sonic edge; Line & edge optional |

| Separate unwind for 1000mm diameter unwind rolls | Optional |

| Nip design | Driven ac vector motor, pneumatically actuated |

| Rewind operator view table | Standard; synchronized strobe |

| Rewind shafts | Single shaft – bi directional |

| Rewind standard shafts | Quick change air shaft |

| Rewind differential shaft option | N/A |

| Rewind tension system | Auto control by calculation |

| Rewind tension control | Driven AC vector motor |

| Lay-on roller for rewind shafts | N/A |

| Web clamps for rewinds | Standard |

| Waste & trim removal | Optional |

| Splice table | Standard |

| Razor Slitting | N/A |

| Shear slitting | Standard – 3 knives |

| Smart label counter management system – two systems available | The LC1 smart counter uses advanced technology complemented by advanced inspection algorithms for precise label count. |

| The LC2 smart counter uses advanced technology for precise label count, multi-lane missing label detection, matrix remains detections and automatic fault positioning/management system. | |

| Flag detection | Optional |

| Missing label sensors | 8 Channel optional |

| Capacitive sensor | Optional |

| Reflective sensor | Optional |

| Vision system for 100% inspection separate stand for vision system installation | -Accumulation included for fault position, fault will stop at operator viewing table. -If fault defect confirmed, operator jogs fault to splice table. -Machine speed during 100% inspection – 300m/min -Optional –web guide system and mechanical device for swing table for vision system requirements. |