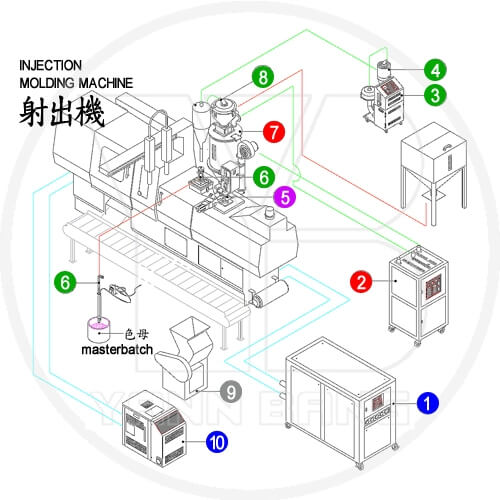

L'IRS est la meilleure solution pour le système de recyclage automatique du plastique en intégrant des granulateurs, des séchoirs à trémie et des chargeurs sous vide. Il convient au recyclage des films, des flocons de PET et d'autres déchets plastiques pour économiser le coût des matériaux vierges.

Dans le passé, les opérateurs jetaient les carottes ou les déchets en petite quantité ou attendaient de les collecter en grande quantité pour les réutiliser. Cependant, cette poussière peut être collée par l'électricité statique devenue trop mauvaise pour être réutilisée pendant un certain temps. Cela occupe non seulement votre espace, mais vous coûte également du temps pour trier, casser la nature plastique et régénérer au cours d'un processus aussi long.

Yann Bang "Système de recyclage instantané" utilise un concasseur pour granuler immédiatement les carottes, les déchets ou le produit NG en petits morceaux en tant que matériau recyclé qui sera mélangé avec du matériau vierge par une vanne proportionnelle dans les bonnes proportions.

Le processus de recyclage vous aide à réduire les dépenses en matériaux sans affecter la qualité. La petite taille avec un faible bruit et une faible consommation d'énergie est idéale pour un fonctionnement de longue durée.

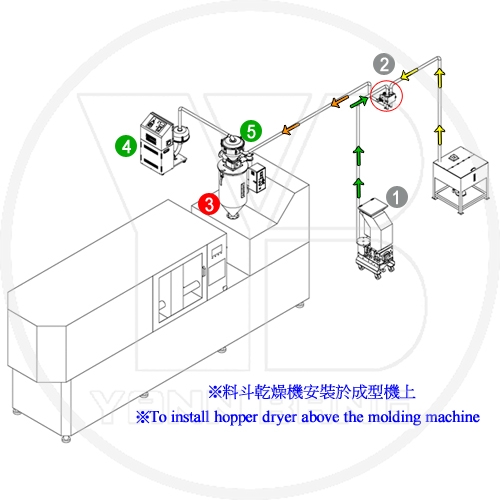

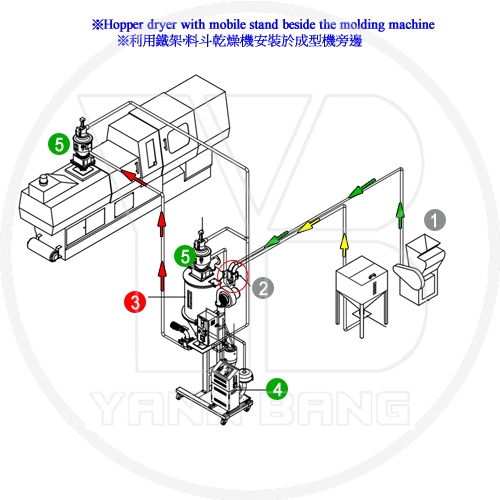

Un petit système de recyclage instantané périphérique automatique pour votre machine de moulage combiné à quatre équipements individuels : broyeur, chargeur sous vide automatique, trémie sécheuse et vanne proportionnelle. Peut également être utilisé avec un robot ou un convoyeur à bande. La fonction principale est de mélanger les déchets granulés directement de la machine de moulage par injection et le matériau vierge avec une bonne proportion. Bénéficiez de moins de matériel et de pollution pour vos productions standard. Le système de recyclage instantané automatique peut recycler, transporter et sécher le matériau granulé de manière séquentielle.

-

Moins de bruit et moins de poussière pour garder votre espace de travail propre.

-

Taille compacte, poids léger et facile à déplacer.

-

Proportion de mélange précise pour une bonne qualité.

-

Le recyclage instantané offre une productivité à haut rendement et réduit le coût des matériaux.

Mighty Crusher (YBC)

- Our crushers are applied to all types of plastic, rubber, resin, and other materials.

- Large feed inlet can break most kinds of plastic or rubber scrap and waste material easily, bulk feeding more efficient, save labor cost and time.

- The main structure is made of high quality steel. It is fracture-proof.

- High-quality blades which increase motor’s efficiencies.

- Able to open widely for better vision.

- With patented(CHINA PAT. ZL200820119883.8) design,once the crusher required for maintenance or repair, the crusher will completely stop as the safety device is on and it is very safe for the operator to open the crusher to clean, check or maintain.

Instant Crusher (YBCS)

- An instant recycling system can help you to cost down by recycling the sprues, waste material or defective products. YANN BANG Instant Crusher is also good to granulate long and thick material.

- This series is perfect to locate next to a molding machine to recycle immediately.

- With patented(CHINA PAT. ZL200820119883.8) design, once the crusher required for maintenance or repair, the crusher will completely stop as the safety device is on and it is very safe for the operator to open the crusher to clean, check or maintain.

Low-Speed Silence Crusher (YBCSS)

- This series are suitable to granulate a small amount of sprues, waste material or defective products located next to your molding machine.

- With low-speed and silence design, it can break evenly and quietly with less dust. Easy to clean and operate with multi safety device.

- With patented(CHINA PAT. ZL200820119883.8) design, once the crusher required for maintenance or repair, the crusher will completely stop as the safety device is on and it is very safe for the operator to open the crusher to clean, check or maintain.

The unique air valve structure design stops dust from entering the cylinder of the unit and thus reduces waste.

Can mix or feed one kind of resin only if required.

The controller is fitted with digital readout (PV-A-D Series) and setting for the mixing cycles which gives a high rate of accuracy. It is easy to set and be set in the range of 0-9.9 seconds.

Transparent cleaning cover design for quick cleaning and easy changing materials.

Individual controller for convenient operation.

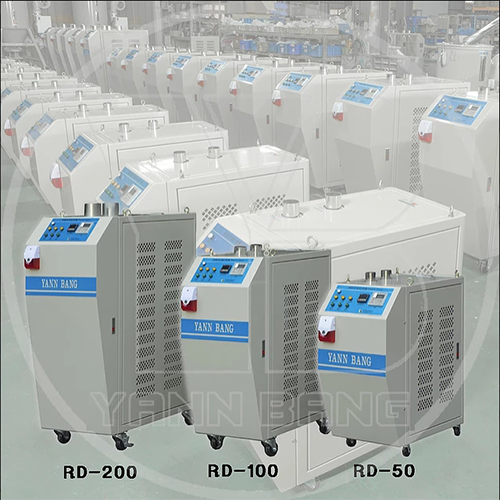

1. Energy-Efficient Hopper Dryer (G series)

Awarded patents in Germany, Taiwan and China, the advanced technology recycles internal heat and faster heating. That saves your energy over 30% and extend equipment life time. Work with a dehumidifier can save more!

The temperature inside hopper increases quickly for better drying and shorten above 30% of drying hour. Simultaneously HEI can separate dust and oil for better quality. An energy-efficient device can save energy and improve working environment for you.

2. Stainless Hopper Dryer For Optics

‧ The perfect dry capacity is special for optics and electronics use.

‧ Unique design is dust-free and clean-free. Stainless and polish one-unit hopper is compact and light weight to install on the molding machine directly.

‧ To see the material level through a sight glass is to make working more efficient.

3. Hopper Dryer (HD/IHD/DHD)

‧ HD Series

Rapid heating.

Constant temperature control.

‧ IHD Series

Special insulated design.

Energy saving.

Save against burns.

‧ DHD Series

Insulated design.

Dust-free, clean free.

The standard DHD model is equipped with timer(T), EGO overheat protector(P),and patented magnetic stand (NSD)

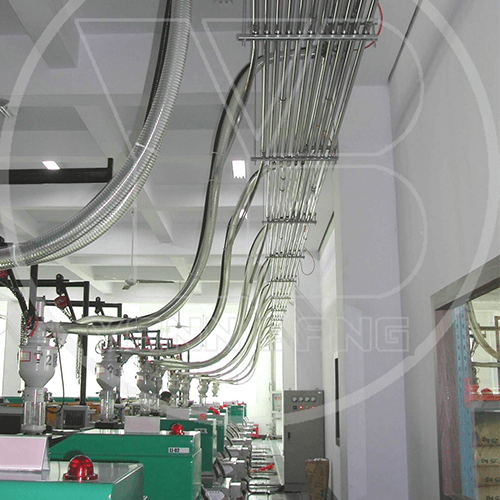

Floor Mounted Auto Vacuum Loader

The separated design of a blower and a suction hopper with mighty horsepower is suitable for long distance conveying. The flexible combination of one blower with one suction hopper up to four suction hoppers can help you to save space and equipment investment cost. That also keeps your resin away the pollution and extend suction points easily for future need.

-

TA series

Easy use by a quiet and powerful induction motor. The motor cabinet can be placed on the floor for convenient operation and the suction hopper on the hopper dryer for easy installation.

-

TB series

Use the same commutator motor as the BC series, and separate motor cabinet and suction hopper design as the TA and TC series. Combine the advantages of the hopper mounted and floor mounted loaders.

-

TC series

The blowers are belt-driven that are the best choice for silent operation.

-

Patented Optional Parts

-

Vortex Cyclone (VC): Works with any auto loaders to stop the regrinded resin from discharging to the surrounding area.

-

Filter Set: s optional equipment from YANN BANG is perfect for dust-free of indoor working place. To do the filter routine maintenance is so easy without dirtying your hands and place. Unload the filter set without opening the cover until move to the please you want to clean.

-

Auto Dust Cleaner: Saves your time and labor. No need to clean your filter anymore. The Auto Dust Cleaner is designed to install upon the filter of the loader. Set the timer and it cleans your filter routinely.

Suction Hopper

-

Standard Series (HS)

By negative pressure principle, convey the raw material into the hopper controlled by the limited switch.

-

Glass series (GS)

Fitted with a proximity switch to make the accurate control and the material supply easily observed. It can be mounted directly onto the molding machine and gives the operator a clear view of the loading through the sight glass.

-

Stainless Series for Optics (HS-S/GS-S)

The stainless suction hopper which is internal buffed is dust-free and best choice for optics industry.

-

Booster Series (HS-E)

Flexible Hopper design to increase or decrease your hourly capacity is economic and user-friendly.

-

Dust-Free Filter Hopper for optics (HDF)

During conveying, dust and resin are separated. To compare with other air filter, it can increase 300% efficiency to de-dust. Stainless design with transparent tempered glass gives a clear view of the loading, and it is perfect for optics need of dust-free.

-

Powder Series (HSP)

Working with a floor-type auto loader (TAE series) .It is the best choice for powder user. Available for powder, pellet or flake resin. Both new and recycled material are no problem. Special design to prevent dust and keep workshop clean. No longer worry about the powder jam at the bottom.

- Sent the recycled material instantly to the discharge bin by compressed air.

- Unique design avoids pollution for good quality.

- The filter can keep your working place clean.

- The discharge outlet with multiple designs is great for your different uses.

- The feeder and base can adjust the output of raw resin or recycling material.

- To speed up the air inside pipe by 4-6kgf/cm² compressed air conveys the recycled material to the discharge bin.