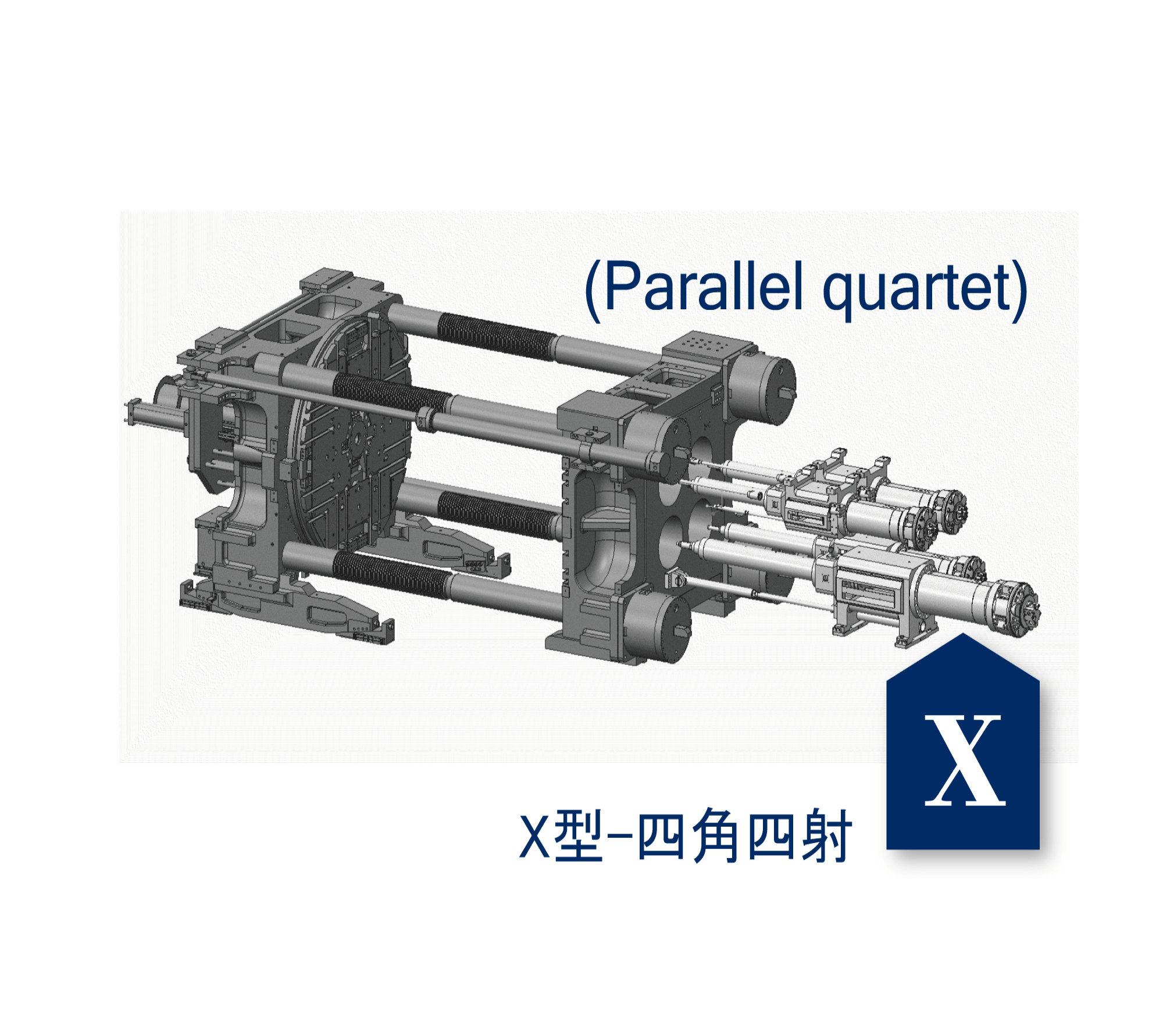

A New Product From The FCS Multi-Component Injection Molding Machine Line Has Been Released: The Debuts Of The X-Type Parallel Quartet-Injection Molding Machine!

The multi-component molding technology solution of FCS Group (FCS) has embraced a new product: The X-type parallel quartet-injection molding machine. This technology has been introduced to the FCS large multi-component injection molding machine line. The first GW-1600R large two-platen multi-component injection molding machine (quartet-injection molding machine) has been delivered to a well-known Chinese automotive lamp supplier for mass production.

Photo/The GW-1600R quartet-injection molding machine has been put into mass production by the client.

The cost of headlamps, as the most critical component of a vehicle, determines the cost structure of the vehicle. Currently, the best-selling 30 cars in the market mainly adopt LED and "halogen + LED" headlamps. Specifically, "halogen + LED" headlamps represent approximately 50% of the total number of headlamps. General car models mostly use halogen headlamps, while high-end ones employ LED headlamps.

Overall, LED headlamps are now the mainstream of the market. Statistics show that the penetration rate of LED headlamps in the global passenger car market surpassed 50% in 2020. Additionally, according to the Customs of China, the import and export of electrical lighting devices for motor vehicles have been growing steadily since 2015. Particularly, thanks to the surge in sales of new energy vehicles (NEVs) and the rebound effect of consumption, the overall import and export volumes rose significantly in 2021 to 52.86 million and 413.36 million sets, respectively. It is expected that the overall import and export will maintain the growth trend amid the continuous penetration of NEVs.

In recent years, not only rear lamps adopt the design that connect the left and right lamp visually, but also headlamps with the run-through connect design are nothing new now due to the discard of the front air inlet of NEVs. Such headlamps are trendier technologically. As new appearances of NEVs constantly emerge, the functionality of headlamps is being improved in size, precision, and stability. Therefore, multi-material processing machines have been much sought after by headlamp suppliers.

Photo/ (left) general headlights; (right) tail light of the run-through design.

Photo/ (left) general headlights; (right) tail light of the run-through design.

In response to such demand, FCS has launched the X-type parallel quartet-injection multi-component solution. Compared with the previous L-type quartet-injection solution, the X-type parallel quartet-injection molding machine occupies a smaller area and features a more concentrated injection structure. Its four injection units can be applied to a wide range of molds, and thus two-component, three-component, and four-component products can be efficiently and flexibly produced.

Furthermore, FCS offers an X-type parallel quartet-injection solution, which is the preferred brand of multi-component equipment, given its higher cost performance and advantages in the delivery cycle and after-sales services. This product line has been warmly received immediately after its launch. We will launch X-type parallel quartet-injection molding machines with a larger tonnage. Stay tuned!

-web-01.jpg)

The characteristics of the new X-type parallel quartet-injection multi-component injection molding machine:

1. A two-platen clamping unit, a concentrated layout of injection units, and small area occupation favorable for factories to allocate space.

2. The four injection units are arranged in parallel up and down on the fixed mold side. The concentrated structure and flexible layout meet the injection molding requirements of diverse products.

3. The injection units to use can be flexibly selected according to mold requirements. Two-component, three-component, and four-component products can be efficiently produced without moving or changing the injection units.

4. The high accurate servo rotary table can be rotated for multiple angles and tasks. Additionally, it features precise positioning and high-speed operation.

As of the end of October 2022, more than 800 FCS large and medium-sized multi-component injection molding machines were sold cumulatively to the automobile industry at the cumulative price of RMB 1.7 billion, with a total clamping force exceeding 800,000 tons. The development of larger and electric multi-component injection molding machines and the launch of more new structures and products with a larger tonnage by FCS will drive the NEV industry to be more prosperous!

- Read More (1):FCS Has Become BYD Auto's Supplier For The Multi-Component Injection Molding Machines, With An Amount Of Accumulative Order Of Approximately RMB 200 Million

- Read More (2):The Market Size Of Injection Molding Machines Is Growing Steadily Under The Normal State Of Automotive Lightweighting